Preparation method of carbon fiber surface composite coating

A surface composite, carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, fabric surface trimming, etc., can solve the problem of the weak interface between carbon fiber and resin matrix, etc., to increase the surface roughness and surface energy, good effect and close connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

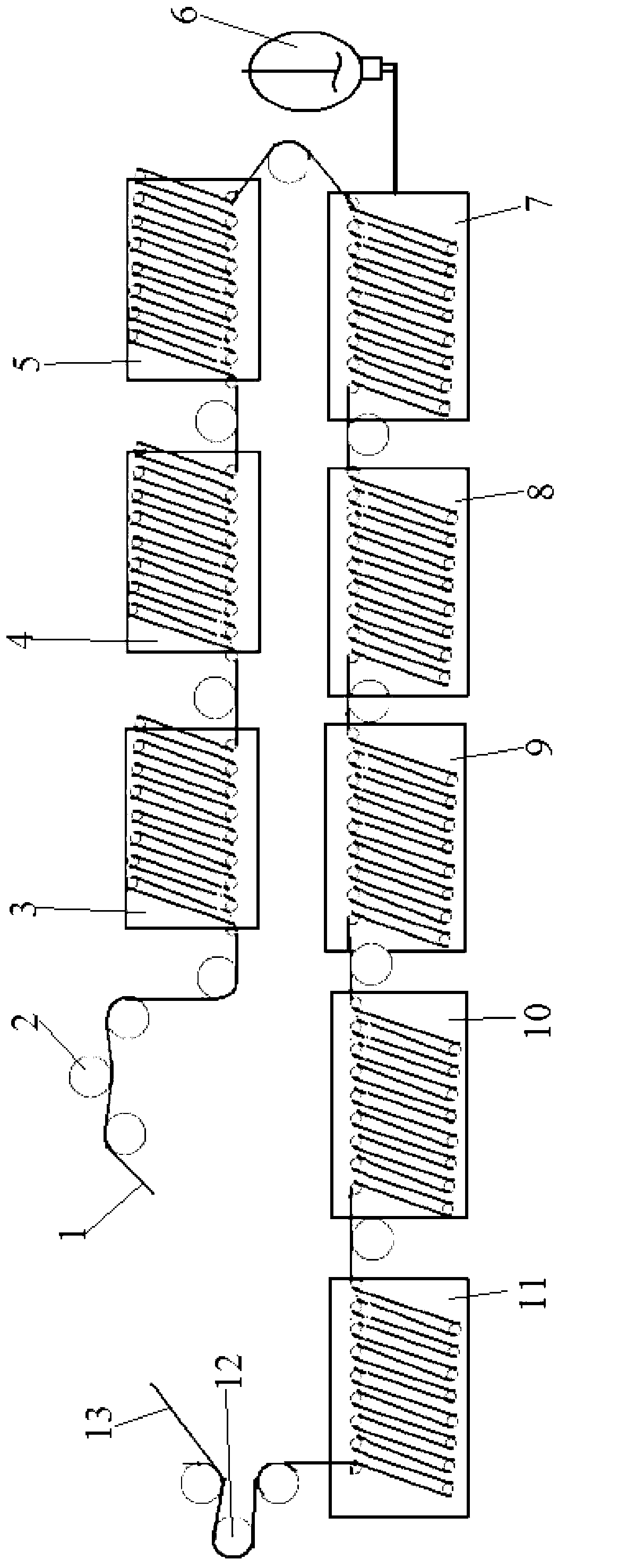

Image

Examples

specific Embodiment approach 1

[0009] Specific Embodiment 1: This embodiment is a preparation method of a carbon fiber surface composite coating, which is specifically completed according to the following steps: 1. Pretreatment of carbon fibers: first, carbon fibers are pretreated on the fiber surface, and the pretreatment is 1min to 120min , the surface pretreated carbon fiber is obtained after taking it out, and the surface pretreated carbon fiber is washed with deionized water for 1min~120min, and then the washed surface pretreated carbon fiber is placed in an oven at a temperature of 90°C~500°C Drying for 1min~60min, the pretreatment of carbon fiber is completed, and the pretreated carbon fiber is obtained; 2. Coating: soak the pretreated carbon fiber in phenolic resin slurry for 1min~300min, and get the surface coated phenolic resin after taking it out Carbon fibers of resin prepolymers; 3. Curing: Curing the carbon fibers coated with phenolic resin prepolymers obtained in step 2 at a pressure of 0.1MPa...

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pretreatment liquid described in step 1 is acid treatment, plasma treatment or gamma ray treatment. Others are the same as the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the carbon fiber is firstly immersed in the pretreatment liquid to pretreat the surface of the fiber, and the pretreatment lasts for 5 minutes to 110 minutes. For the treated carbon fiber, use deionized water to wash the surface pretreated carbon fiber for 5min~110min, then place the washed surface pretreated carbon fiber in an oven, and dry it at a temperature of 80℃~360℃ for 5min~55min , that is, the pretreatment of carbon fibers is completed to obtain pretreated carbon fibers. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com