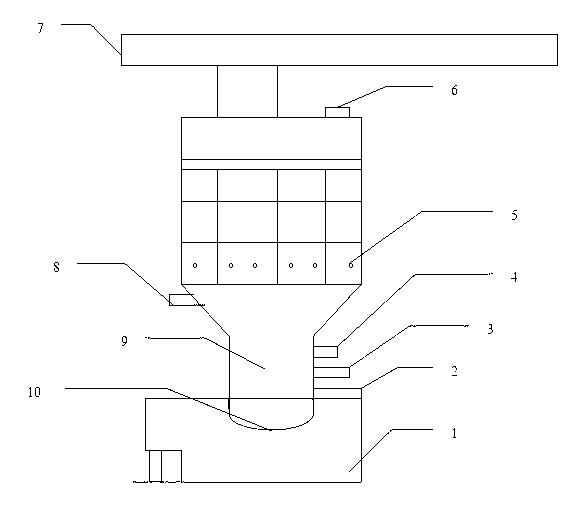

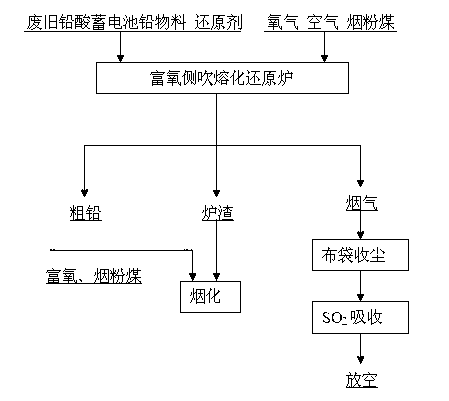

Oxygen-rich side-blown smelting reduction furnace and lead-rich material lead smelting method

A reduction furnace and oxygen-enriched technology, applied in the field of oxygen-enriched side-blown melting reduction furnaces and lead-enriched material lead smelting, can solve the problems of high labor intensity of workers, insufficient coal combustion, low energy efficiency, etc. Improve economic efficiency and accelerate the effect of reduction and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Sample loading: 10t of waste lead-acid battery materials after preliminary treatment are sent into the furnace 9 through the feeding port 6;

[0027] (2) Oxygen-enriched reduction smelting: send oxygen-enriched air with an O2 concentration of 25% into the primary tuyere, the pressure of the primary tuyere is 0.08MPa, and the wind speed is 150m / s, and the pulverized bituminous coal is injected through the coal injection port to adjust the excess oxygen The coefficient α value is 0.3, so that pulverized bituminous coal can be fully burned in the furnace, and the waste lead-acid battery material is heated and kept at a temperature of 1200-1250°C; the reduction reaction is 5 hours, and 7.5t of crude lead is produced;

[0028] (3) Product treatment: crude lead is exported from the first outlet, and then transported to the blast furnace for secondary smelting, while the smoke enters the unified flue gas bag dust removal pipeline system through the flue gas channel for bag ...

Embodiment 2

[0030] (1) Sample loading: 10t of waste lead-acid battery materials after preliminary treatment are sent into the furnace 9 through the feeding port 6;

[0031] (2) Oxygen-enriched reduction smelting: Send oxygen-enriched air with an O2 concentration of 50% into the primary tuyere, the pressure of the primary tuyere is 0.16MPa, and the wind speed is 250m / s, and the pulverized bituminous coal is injected through the coal injection port to adjust the excess oxygen The coefficient α value is 1.0, so that pulverized bituminous coal is fully burned in the furnace, and the waste lead-acid battery material is heated and kept at a temperature of 1200-1250 °C; the reduction reaction takes 5 hours to generate 8 tons of crude lead;

[0032] (3) Product treatment: crude lead is exported from the first outlet, and then transported to the blast furnace for secondary smelting, while the smoke enters the unified flue gas bag dust removal pipeline system through the flue gas channel for bag dus...

Embodiment 3

[0034] (1) Sample loading: 10t of waste lead-acid battery materials after preliminary treatment are sent into the furnace 9 through the feeding port 6;

[0035] (2) Oxygen-enriched reduction smelting: send oxygen-enriched air with an O2 concentration of 40% into the primary tuyere, the pressure of the primary tuyere is 0.12MPa, and the wind speed is 200m / s, and the pulverized bituminous coal is injected through the coal injection port to adjust the excess oxygen The coefficient α value is 0.7, so that pulverized bituminous coal can be fully burned in the furnace, and the waste lead-acid battery material is heated and kept at a temperature of 1200-1250 °C; the reduction reaction is 5 hours, and 7.7t of crude lead is produced;

[0036] (3) Product treatment: crude lead is exported from the first outlet, and then transported to the blast furnace for secondary smelting, while the smoke enters the unified flue gas bag dust removal pipeline system through the flue gas channel for bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com