Method for preparing high polymer micro-nano fiber bragg grating based on nanoimprint lithography

A technology of Bragg grating and micro-nano optical fiber, which is applied in cladding optical fiber, optical mechanical equipment, optical waveguide and light guide, etc., can solve the problems of time and material consumption, and achieve the effect of simple method, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation The micro-nano fiber Bragg grating is prepared using commonly used polymethyl methacrylate as a polymer material, and the steps are as follows:

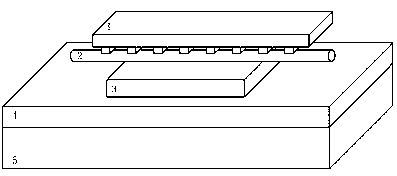

[0028] 1. If figure 1 As shown, first a polydimethylsiloxane film 3 is placed on a glass substrate 4 as a mechanical support. Then place the polymethyl methacrylate micro-nano optical fiber 2 on the polydimethylsiloxane film 3 . The polydimethylsiloxane film has a width of 300 μm and a thickness of about 50 μm.

[0029] 2. Heat the polydimethylsiloxane film 3 and the glass sheet 4 to 120°C with an electric heater 5, which exceeds the glass transition temperature of polymethyl methacrylate (about 100°C).

[0030] 3. Use a commercial planar reflective grating1 as an imprint template with a period of 555 nm (1800 lines per mm). Use a three-dimensional precision adjustment frame to place the grating template vertically on the polydimethylsiloxane film 3, while ensuring that the grating plane is parallel to the polyd...

Embodiment 2

[0036] Also prepare micro-nano fiber Bragg gratings using commonly used polymethyl methacrylate as a polymer material. The width of the film is 300 μm. Other steps and parameters are the same as in Example 1.

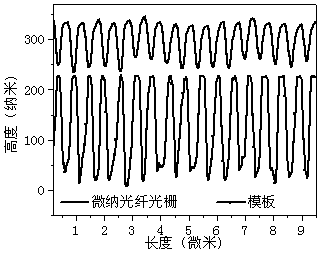

[0037] Figure 5 The transmission spectrum of a polymethyl methacrylate micro-nano fiber Bragg grating with a width of 1.8 μm, a thickness of 1 μm and a grating length of 300 μm is given. It can be seen that the peak of the transmission spectrum is 1518 nm. The experimental results also correspond well with the theoretical calculation results. The grating effect inside the nanoimprinted polymer micro-nano fiber Bragg grating was verified.

Embodiment 3

[0039] Similarly, the commonly used polymethyl methacrylate is used as a polymer material to prepare micro-nano fiber Bragg gratings. The difference between the steps of this method and the steps of preparing nanoribbons is that the applied force is 0.05 N, and the polydimethylsiloxane used The width of the film is 100 μm. Other steps and parameters are the same as in Example 1.

[0040] Image 6 The transmission spectrum of a polymethyl methacrylate micro-nano fiber Bragg grating with a width of 1.1 μm, a thickness of 400 nm and a grating length of 100 μm is given. It can be seen that the transmission spectrum peaks at 1490 nm. The experimental results also correspond well with the theoretical calculation results. The grating effect inside the nanoimprinted polymer micro-nano fiber Bragg grating was verified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com