Simulation optimization method of fuzzy control variable heating temperatures in directional solidification process

A technology of fuzzy control and heating temperature, which is applied in general control systems, control/regulation systems, simulators, etc., and can solve problems such as outstanding process effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

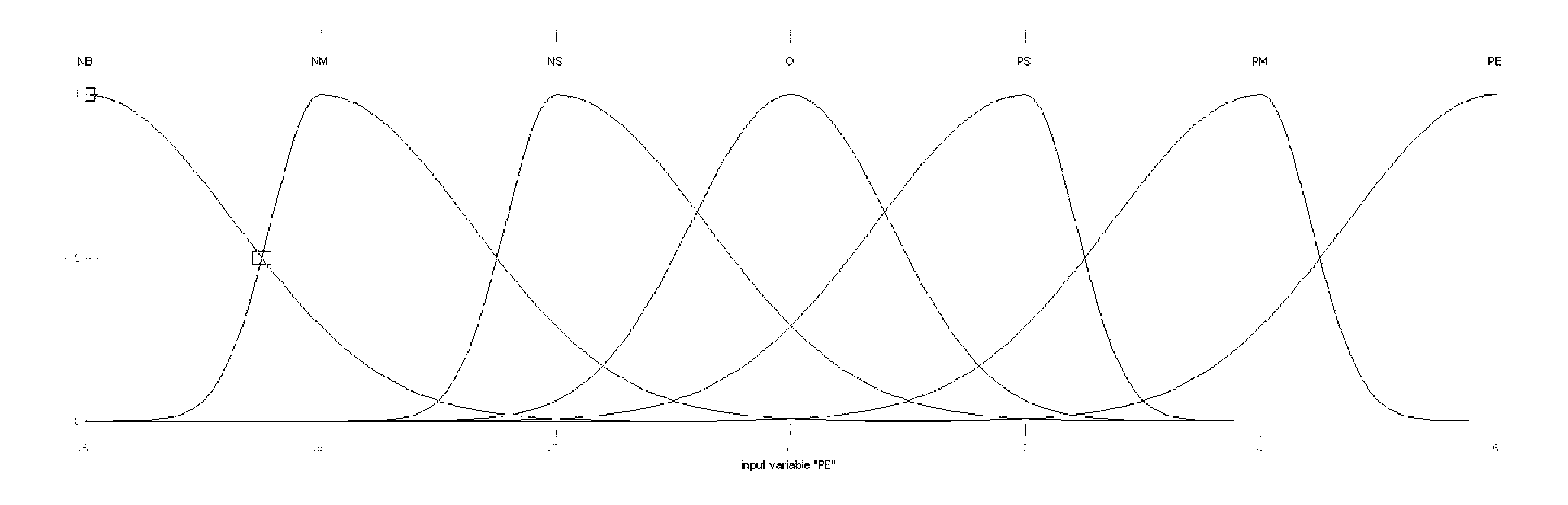

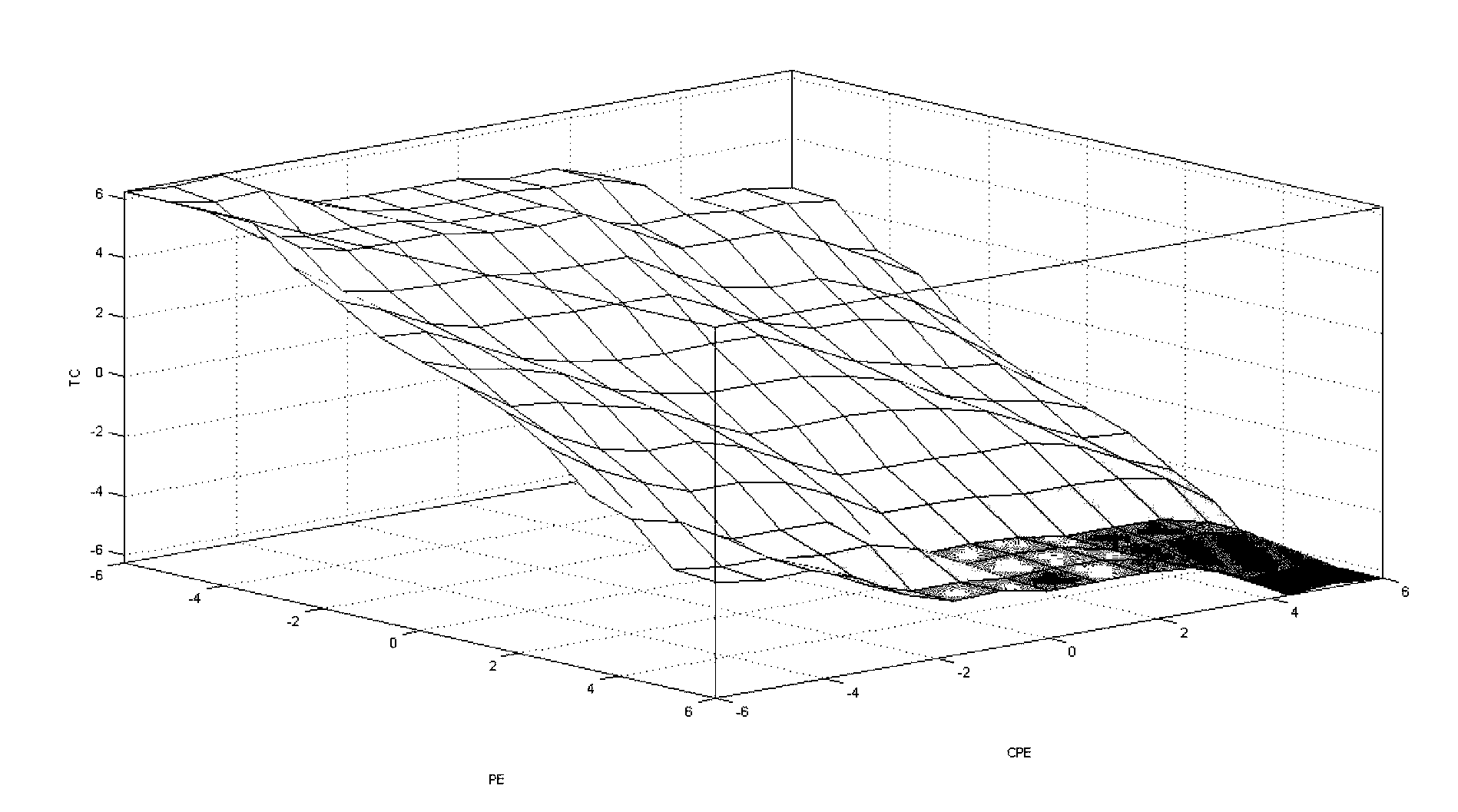

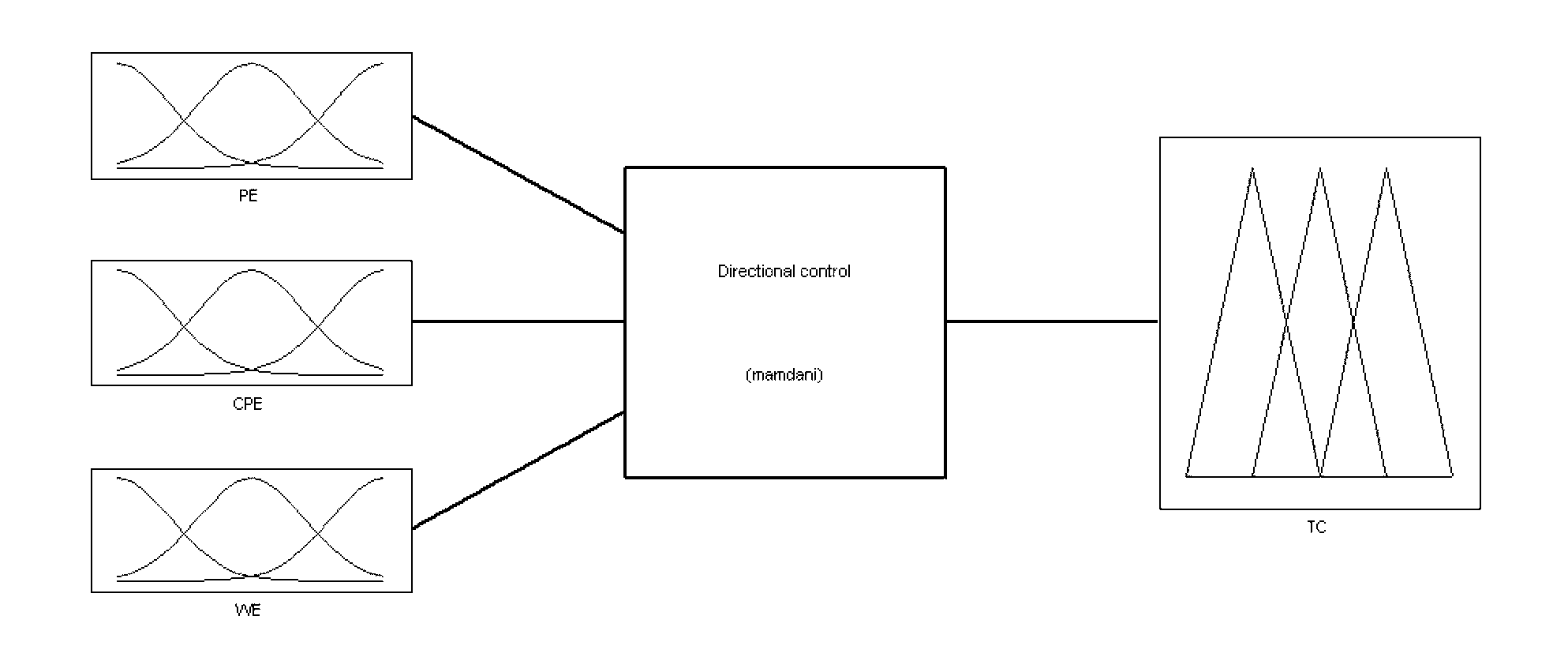

[0084] The principle, structure and process of the present invention will be further described below in conjunction with the accompanying drawings.

[0085] figure 1 A mathematically simplified schematic diagram of a directional solidification device,

[0086] The equipment is based on the Bridgman directional solidification method and is a special equipment for the directional solidification production process. The furnace body of the directional solidification furnace can be divided into a heating zone 1 and a cooling zone 3, wherein the heating zone 1 continues to heat the blade part during the solidification process, and the cooling zone 3. During the solidification process, the part of the blade entering the area is cooled. The baffle plate 2 is responsible for isolating the heating area and the cooling area to increase the temperature gradient. The 4-blade module is generally 6 blade-shaped shells or 3 blade-shaped shells The mould, the pull push rod 5 and the disc crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com