A real-time negative pressure simulation device

A simulation device and negative pressure technology, applied in the field of real-time negative pressure simulation device, can solve the problems of large space, complex structure design and control system design, high requirements on the exhaust volume and depressurization rate of the pressure control system, and achieve simple operation , It is convenient for computer control and the effect of continuous pressure change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

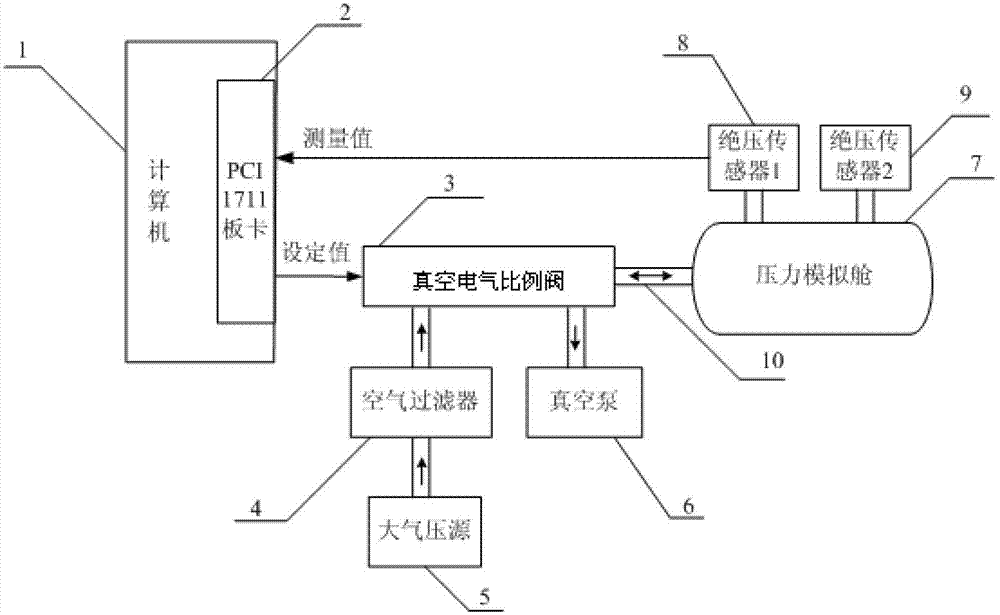

[0020] combine figure 1 The negative pressure real-time simulation device of the present invention includes a computer 1, a PCI-1711 board card 2, a vacuum electric proportional valve 3, an air filter 4, an atmospheric pressure source 5, a vacuum pump 6, a pressure simulation cabin 7, an absolute pressure sensor I 8, an absolute pressure Sensor II 9 and gas pipeline 10.

[0021] The PCI-1711 board 2 is installed in the computer 1; the PCI-1711 board 2 is connected with the absolute pressure sensor Ⅰ 8 and the vacuum electrical proportional valve 3 through the data line; the atmospheric pressure source 5 passes through the gas pipeline 10 and passes through the air filter 4 and the vacuum electrical proportional valve The pipeline interface of the valve 3 is connected; the vacuum pump 6 is connected with the pipeline interface of the vacuum electrical proportional valve 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com