Manufacturing device of bus bar and manufacturing method thereof

A technology for a manufacturing device and a manufacturing method is applied to the manufacturing device of a bus bar and the manufacturing field thereof, which can solve the problems such as the inability to sufficiently reduce the unit price of the bus bar, and achieve the effects of reducing the burden of management and simplifying the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

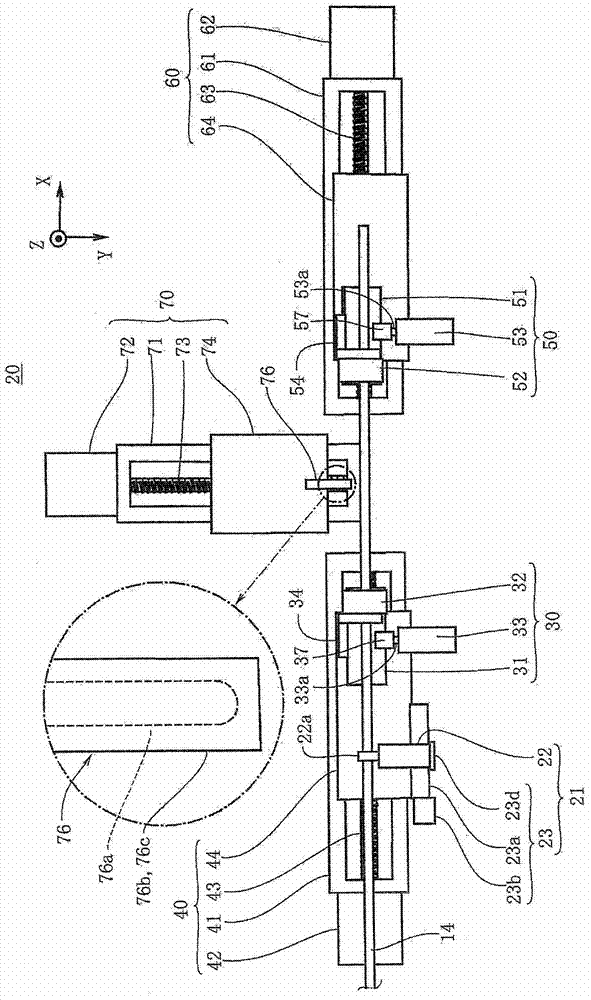

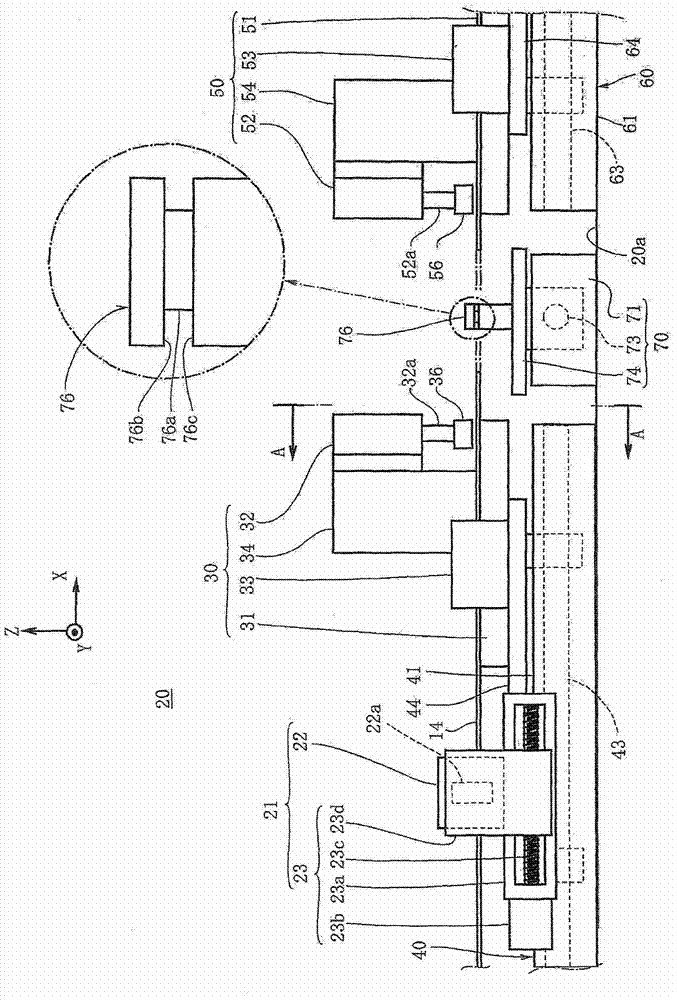

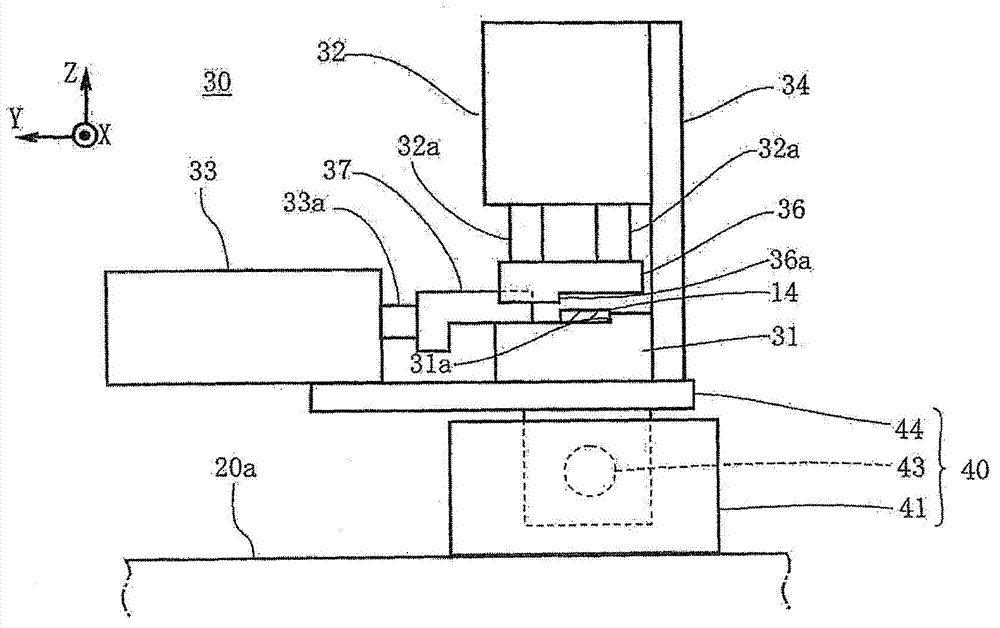

[0029] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

[0030] figure 1 as well as figure 2 The manufacturing apparatus 20 of the bus bar of this invention is shown. Such as Figure 9 As shown, the manufacturing device 20 automatically manufactures the elongated and elongated main body portion 12a, and the main body portion 12a extending from the predetermined position of the main body portion 12a to the main body by bending the metal elongated square wire 14. The bus bar 12 is the fins 12b, 12c protruding in a folded or cantilever shape in the direction where the portion 12a intersects.

[0031] For the square wire 14, a relatively thick wire material that can maintain its shape when bent is used. In this embodiment, a case is shown in which a so-called square wire 14 is used, and the cross section of the square wire 14 on which an insulating film is formed on the surface is formed in a rectangular shape. If ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com