MIM (metal-insulator-metal) capacitor and manufacturing method thereof

A manufacturing method and technology of capacitors, which are applied in the direction of circuits, electrical components, and electric solid devices, can solve problems such as MIM capacitor short circuit, dielectric layer breakdown, affecting product yield and reliability, etc., to reduce process complexity, The effect of reducing the probability of breakdown and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

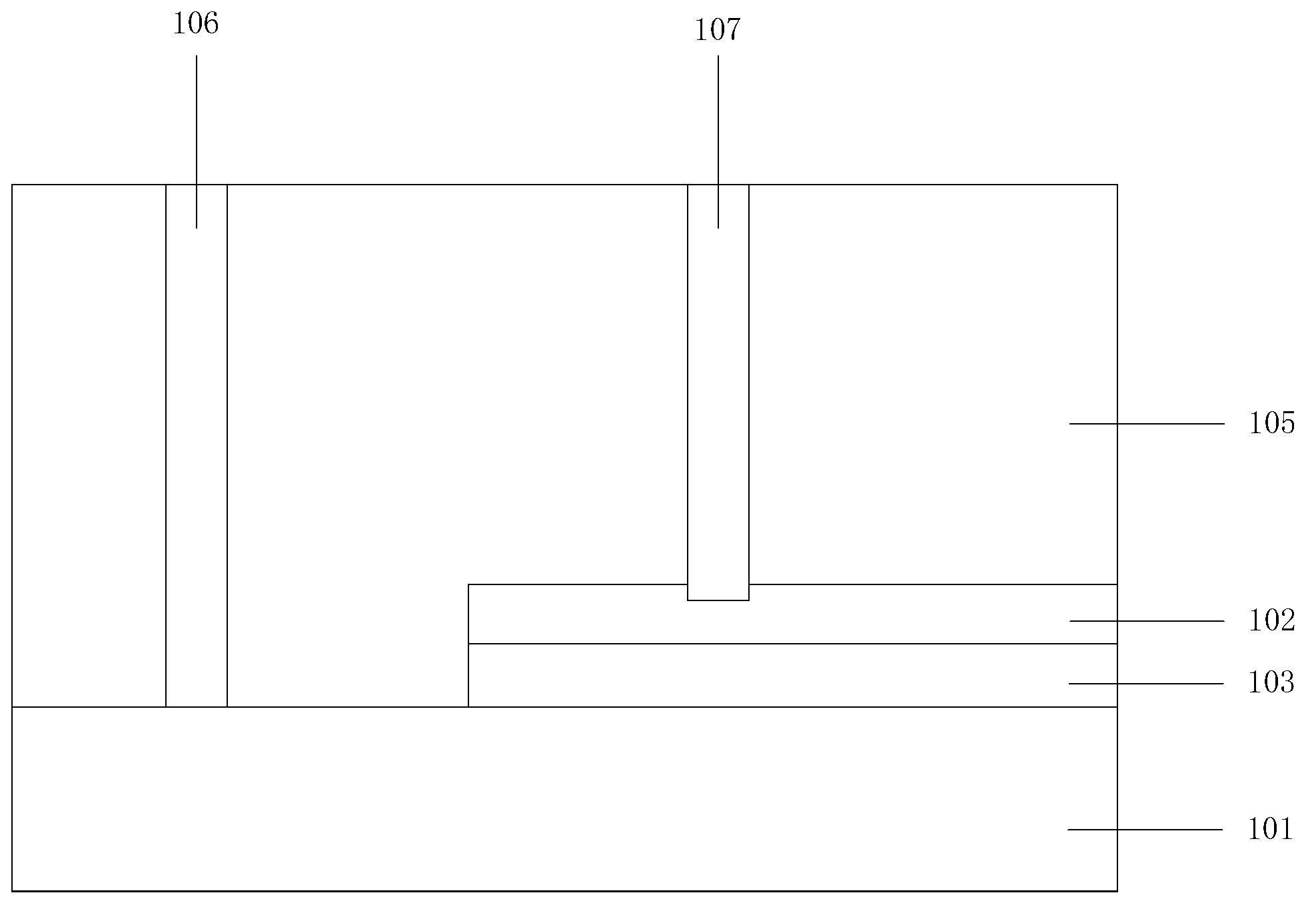

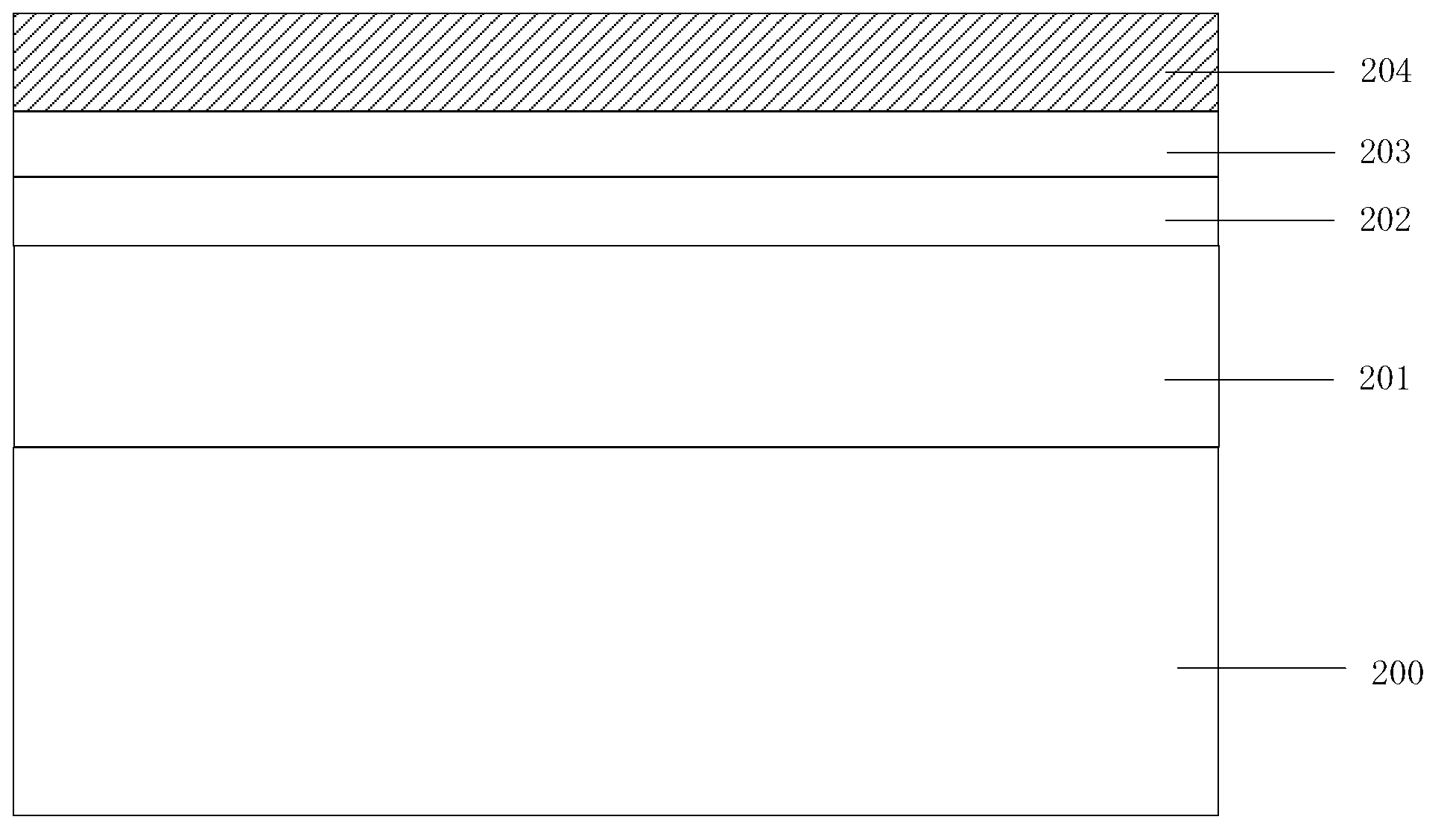

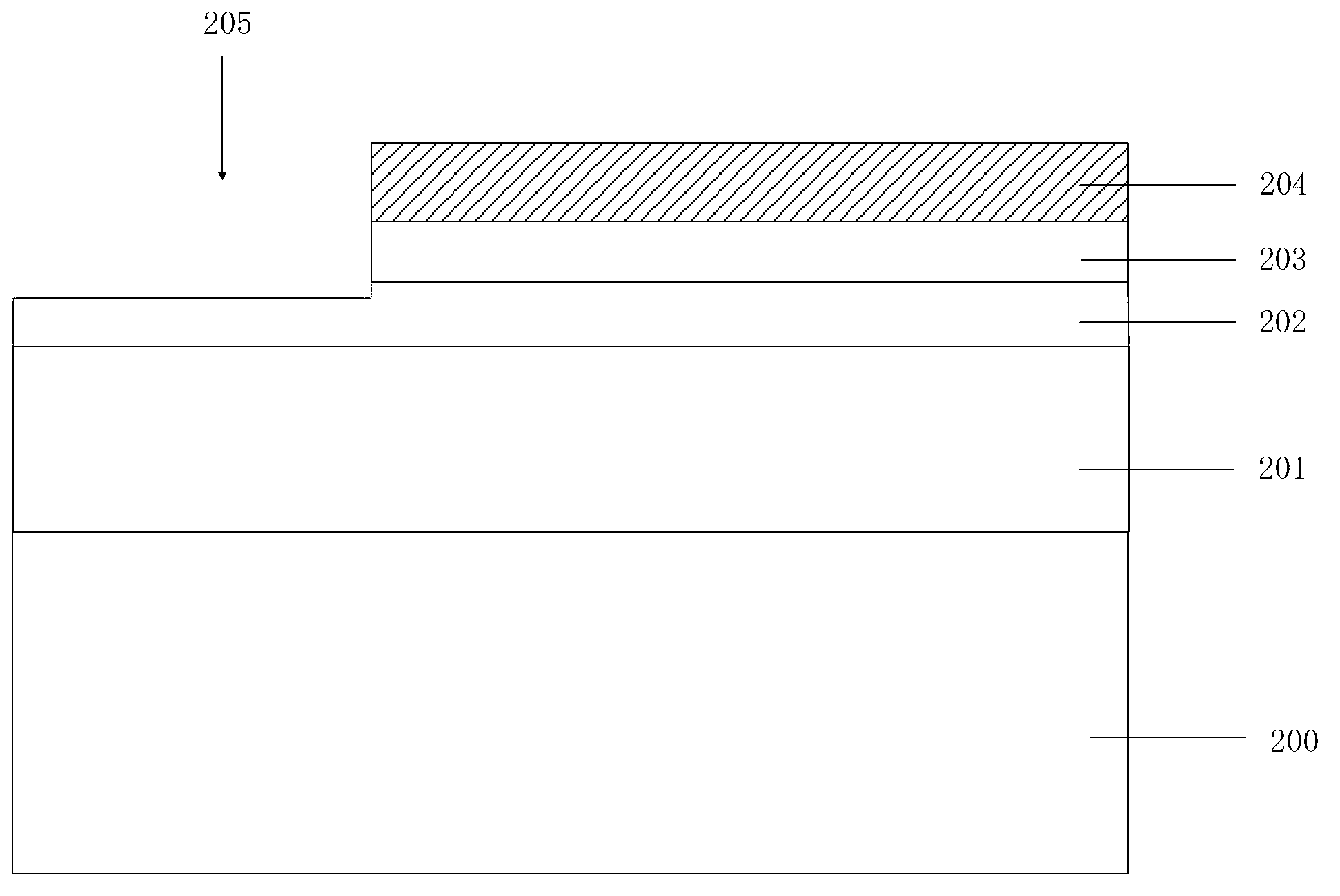

[0035] Figure 2 to Figure 6 Shown is a schematic cross-sectional view of the structure of a method for manufacturing an MIM capacitor. Combine the following Figure 2 to Figure 6 The technical solution of this embodiment will be specifically described.

[0036] First, refer to figure 2 As shown, step S11 is performed: a substrate 200 is provided, and a first conductive layer 201 , a capacitor dielectric layer 202 , a second conductive layer 203 and a cover layer 204 are sequentially deposited on the substrate 200 from bottom to top.

[0037] The substrate 200 provided in this step may be a semiconductor substrate on which a premetal dielectric (PMD) is formed, or a semiconductor substrate on which various devices or metal interconnect structures are formed. Conductive layer 201 is electrically insulated from pre-formed various devices or metal interconnect structures.

[0038]The first conductive layer 201 formed in this step is used to form the lower plate of the MIM ca...

Embodiment 2

[0054] The structure and fabrication method of the MIM capacitor provided in the second embodiment are substantially the same as those in the first embodiment. The difference lies in: the material and thickness of each layer of the capacitor dielectric layer 202 and the cover layer 204 deposited in step S11, the thickness and material of the dielectric layer 206 formed in step S13, and the dry etching gas selection in step S14, It satisfies that the two through holes 208 and 207 formed by the dry etching in step S13 expose the second conductive layer 203 while exposing the first conductive layer 201 . In other words, the above etching process will not cause damage to the upper electrode plate and the lower electrode plate, and the accumulation degree of positive charges in the upper electrode plate is further reduced, thereby further improving the reliability of the MIM capacitor.

[0055] Specifically, for the case where the capacitor dielectric layer 202 and the cover layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com