Coating type nano-palladium film catalytic electrode and its preparation method

A catalytic electrode and nano-palladium technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of nano-carbon powder loss, easy agglomeration, toxicity, etc., and achieve the effects of improved stability, good repeatability, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

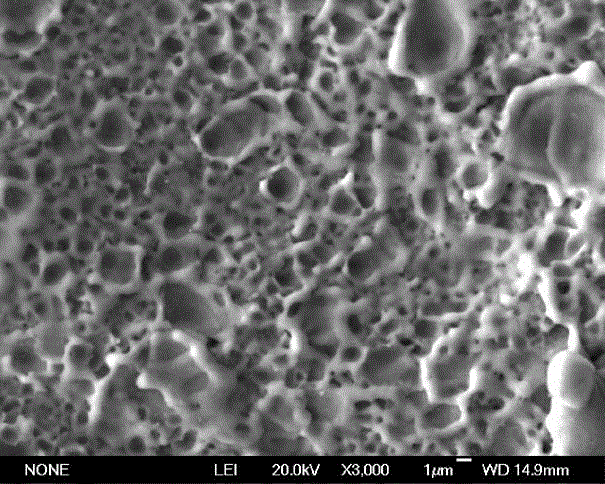

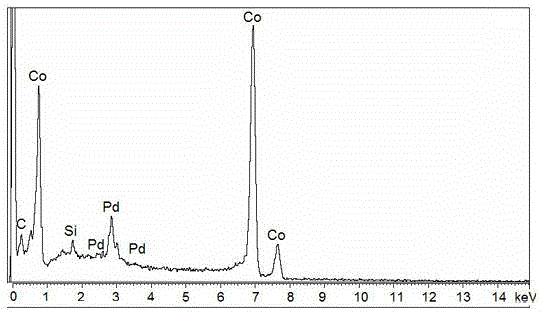

[0031] Embodiment 1: a kind of coating type nano-palladium thin film catalytic electrode, catalytic electrode is that diameter is 13 millimeters, the metal cobalt sheet that height is 2 millimeters, described metal cobalt sheet purity is more than 99.5wt.%, in described cobalt sheet The upper surface is coated with palladium metal with a composition of 10at.%, the two are metallurgically bonded, the surface microscopic appearance is sputtered spot shape, and the spot size is 10 microns.

[0032] Concrete preparation method is finished as follows:

[0033] (1) Wire-cut a cobalt rod with a diameter of 13 mm and a purity of 99.5 wt.% into discs with a height of 2 mm, and then at room temperature, use 600, 2000-mesh metallographic sandpaper to grind and polish it until bright, respectively. Sonicate in deionized water and absolute ethanol for 10 minutes, remove to dry.

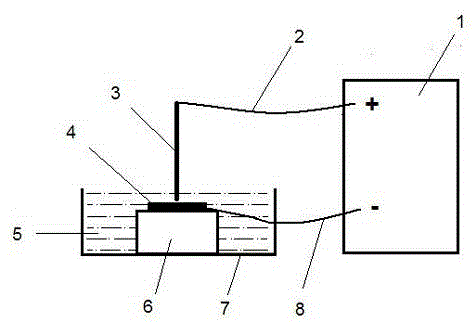

[0034] (2) if figure 1 As shown, the pretreated cobalt sheet 4 is immersed in a silicone oil bath 5 at a temp...

Embodiment 2

[0039] A coating type nano-palladium thin film catalytic electrode, the catalytic electrode is a metal cobalt sheet with a diameter of 15 mm and a height of 4 mm, the purity of the metal cobalt sheet is 99.95wt.%, and the upper surface of the cobalt sheet is coated with a composition of 80.at.% palladium metal, the two are metallurgically bonded, the surface microscopic appearance is sputtered spots, and the spot size is 100 microns.

[0040] Concrete preparation method is finished as follows:

[0041] (1) Wire-cut a cobalt rod with a diameter of 15 mm and a purity of 99.95 wt.% into discs with a height of 4 mm, and then at room temperature, successively grind and polish with metallographic sandpaper of 600 and 2000 mesh until bright, respectively Sonicate in deionized water and absolute ethanol for 20 minutes, remove to dry.

[0042] (2) Immerse the pretreated cobalt sheet in a silicone oil bath at a temperature of 35°C, place it 1 mm below the liquid surface, lead a wire fr...

Embodiment 3

[0046] A coating type nano-palladium thin film catalytic electrode, the catalytic electrode is a metal cobalt sheet with a diameter of 20 mm and a height of 5 mm, the purity of the metal cobalt sheet is above 99.99wt.%, and the upper surface of the cobalt sheet is coated with Covered with palladium metal with a composition of 70.at.%, the two are metallurgically bonded, and the surface microscopic appearance is sputtered spot-like, and the spot size is 0.1 micron.

[0047] Concrete preparation method is finished as follows:

[0048] (1) Wire-cut a cobalt rod with a diameter of 20 mm and a purity of 99.99 wt.% into discs with a height of 5 mm, and then at room temperature, successively grind and polish with metallographic sandpaper of 600 and 2000 mesh until bright, respectively Sonicate in deionized water and absolute ethanol for 30 minutes, remove to dry.

[0049] (2) Immerse the pretreated cobalt sheet in a silicone oil bath at a temperature of 40°C, place it 2 mm below the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com