Recovering technology for waste acid

An acid recovery and process technology, applied in the field of waste acid recovery process, can solve the problems of long delay time for process parameter adjustment, complex process, and many power equipment, and achieve the effects of easy control, more process parameters, and less power equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

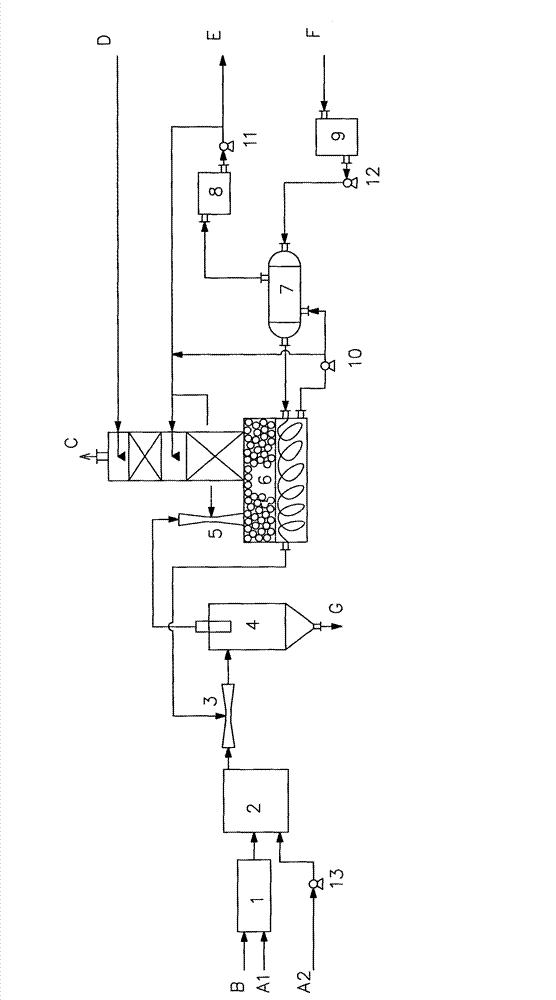

[0015] Referring to the accompanying drawings, the whole process is composed of a vaporization separation process, an absorption separation process, and a waste acid preheating process.

[0016] (1) The vaporization separation process consists of a combustion device 1 , a temperature-controlled gas box 2 , a Venturi tube 3 and a cyclone separator 4 . Using gas as energy, gas B is pressurized to ≥5KPa and enters burner 1, air A is pressurized by blower 13 (≥5KPa), enters combustion chamber and temperature control gas box 2, enters Venturi tube 3, and enters Venturi tube 3 Throat sucks the preheated waste acid, vaporizes it quickly and enters the cyclone separator 4. The operating temperature of the cyclone separator 4 is controlled at about 380°C. Impurities (acid slag G) in the waste acid are separated in the cyclone separator 4. After separation, the flue gas is sent to the absorption separation process.

[0017] (2) The absorption and separation process is composed of a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com