Method for degrading eupatorium adenophorum into fermentable reducing sugar

A technology of Eupatorium adenophorum and degradation time, applied in fermentation, biofuel, etc., can solve the problems of no process technology, low recovery rate, large acid and alkali consumption, etc., and achieve the effect of reducing cost, shortening time, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

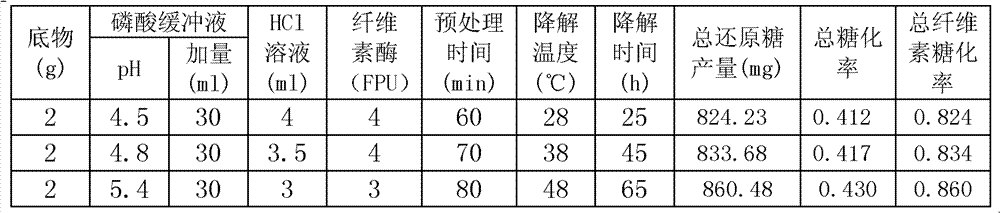

[0026] Dried Eupatorium adenophorum, weighed, and mechanically crushed into 30-mesh Eupatorium adenophorum powder, without sieving, added to the above-mentioned Eupatorium adenophorum powder at a solid-liquid ratio of 1:6-20 Phosphate buffer solution, based on the amount of buffer solution, add 1-7ml HCl solution with a concentration of 0.10mol / L per 50ml buffer solution for pretreatment for 5-180min to obtain a treatment reaction solution; select commercially available cellulase Enzyme, cellulase is added to the above-mentioned treatment reaction solution at the weight of 1.5-4.5 FPU / g Eupatorium adenophorum for degradation, the temperature of the degradation process is kept at 28-45° C., and the degradation time is 6-72 hours. The entire reaction process of pretreatment and degradation is carried out in a shaking table, and the rotating speed of the shaking table is kept at 100r / min. The concrete experimental data of embodiment is shown in Table 1:

[0027] Table 1

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com