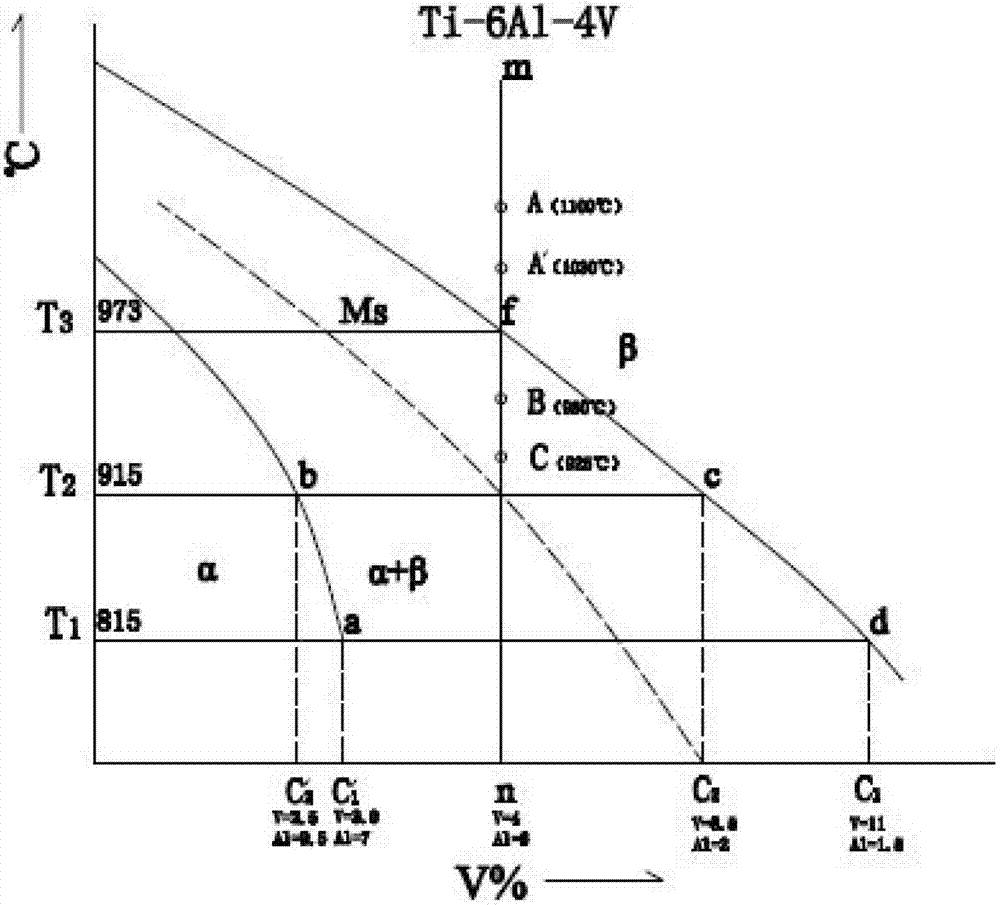

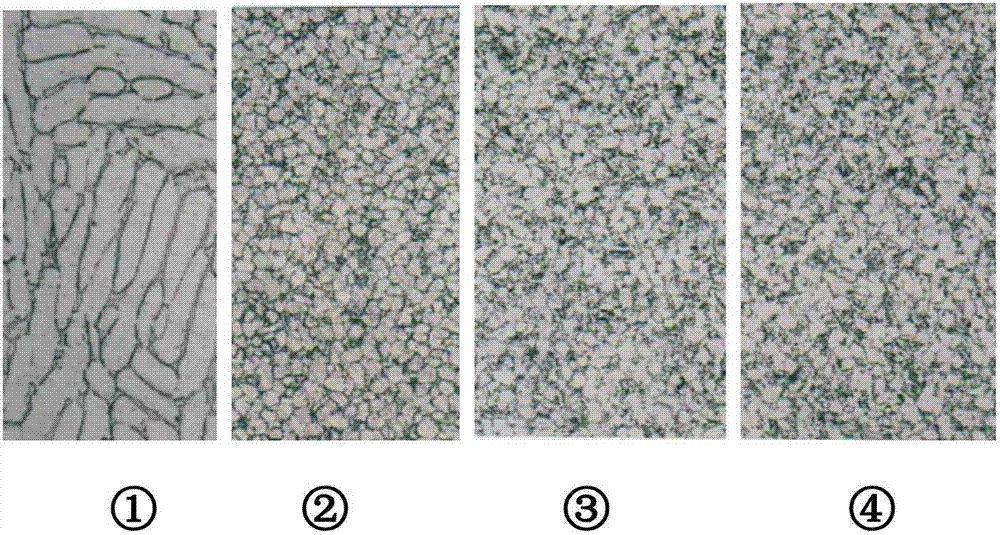

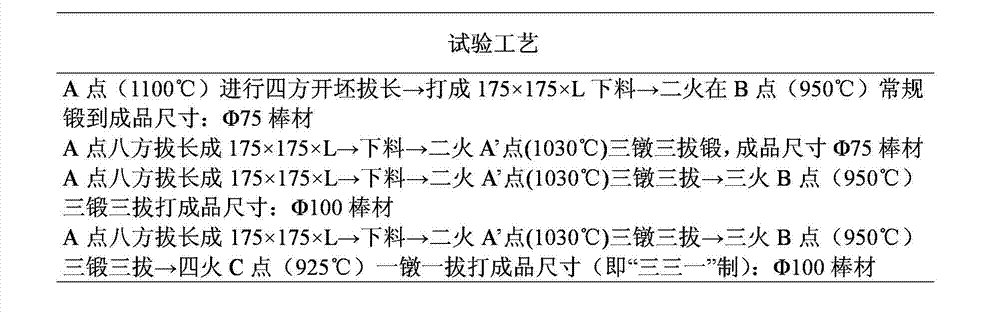

Preparation technology of titanium alloy under ultralow temperature condition

A preparation process, titanium alloy technology, applied in the field of titanium alloy preparation process, can solve the problem that titanium alloy cannot meet the ultra-low temperature requirements, and achieve the effect of improving plasticity, good structure uniformity, and wide application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preparation process for titanium alloys under ultra-low temperature conditions according to the present invention is as follows:

[0021] The first step, mixing: take Ti 1288.2Kg, Al 89.28 Kg, V59.04 Kg, Fe 1.44 Kg, O 0.86Kg, H 0.028 Kg, Zr 1.152 Kg, put them into the distributor and mix them fully, the particle size of Ti particles The particle size of Al, V and Zr is 0.2-2.5mm;

[0022] The second step, electrode production: Put the alloy mixed in the first step into the mold of a 2500-ton vertical hydraulic press to extrude the electrode. The weight of each electrode is 45Kg, and a total of 32 electrodes are produced;

[0023] Step 3: Smelting in a vacuum furnace: Put the electrode made in the second step into a vacuum furnace for smelting. In the vacuum furnace, Φ300*L, Φ380*L and Φ480*L should be smelted three times. The specific smelting The process is as follows:

[0024] First smelting: After using the argon arc welding machine to weld the eight electrodes m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com