Preparation method of one-dimensional magnetic nanowire array with ultrahigh axial remanence ratio

A magnetic nanometer and remanence ratio technology, applied in nanotechnology, chemical instruments and methods, single crystal growth, etc., can solve the problems of low magnetic parameters and can not meet the needs of practical applications, and achieve good universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

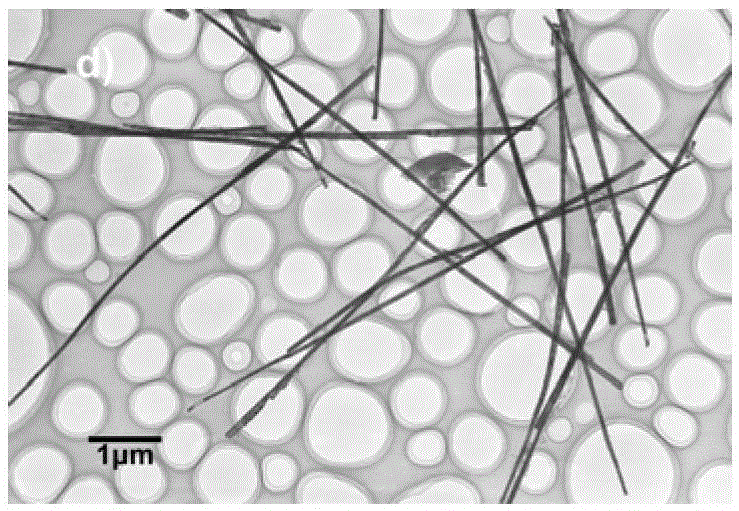

Image

Examples

Embodiment 1

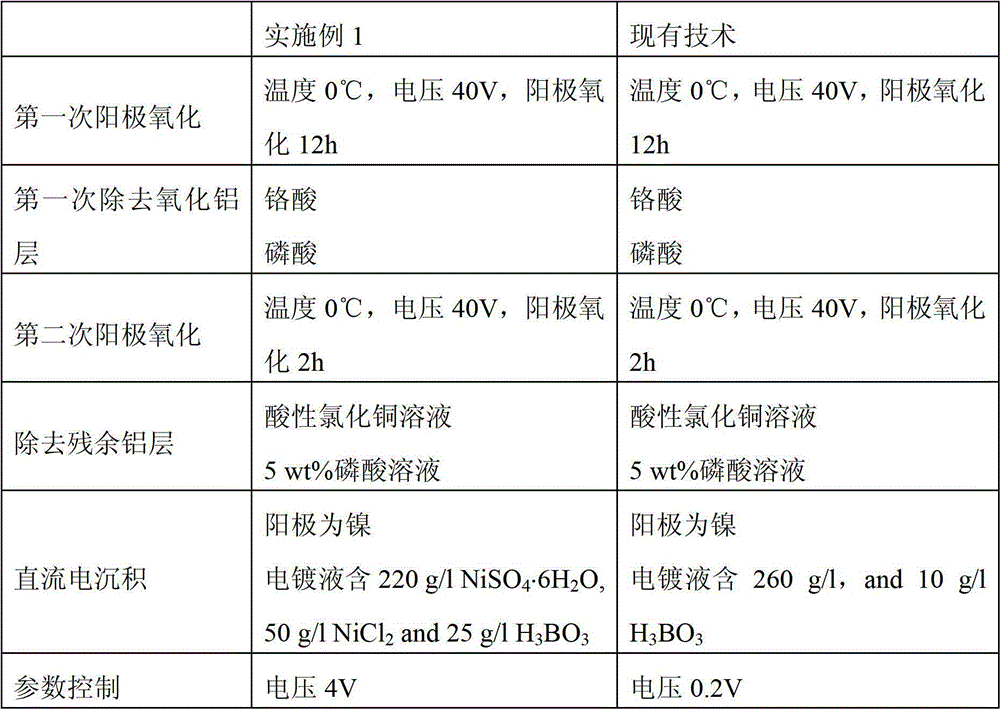

[0054] Embodiment 1 takes the alumina template as an example, and the preparation process of the alumina template includes the following steps:

[0055] a1. The first anodic oxidation: the degreasing and polished aluminum sheet is used as the anode, copper is used as the cathode, the electrolyte is phosphoric acid, the temperature is kept at 0°C, the voltage between the electrodes is 40V, and the anodization is performed for 12 hours. Alumina layer.

[0056] a2. Removing the alumina layer for the first time: use a mixed solution of 15wt% chromic acid and 10wt% phosphoric acid in a volume ratio of 1:5 to remove the generated alumina layer and wash it.

[0057] a3. The second anodic oxidation: the aluminum sheet after removing the alumina layer in step a2 is used as the anode, and the copper is used as the cathode, and the second anodic oxidation is carried out. Anodize for 2 hours.

[0058] After the second anodization, a uniformly distributed alumina channel array is formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com