Method for increasing foundation bearing capacity

A foundation bearing capacity and bearing capacity technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of long time for foundation treatment, high treatment requirements, and affecting development speed, etc., so as to reduce the amount of consolidation settlement and improve Effects of processing efficiency and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] A method for improving the bearing capacity of the foundation proposed by the present invention, which organically combines vacuum preloading technology and soft foundation grouting technology, specifically includes the following steps:

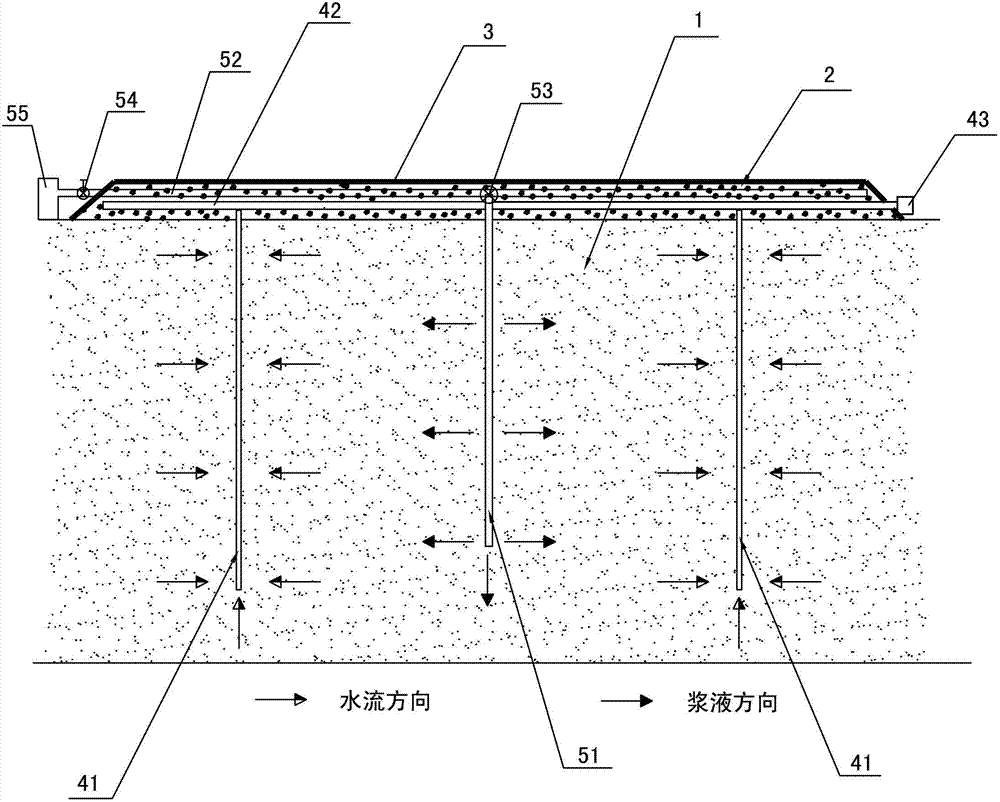

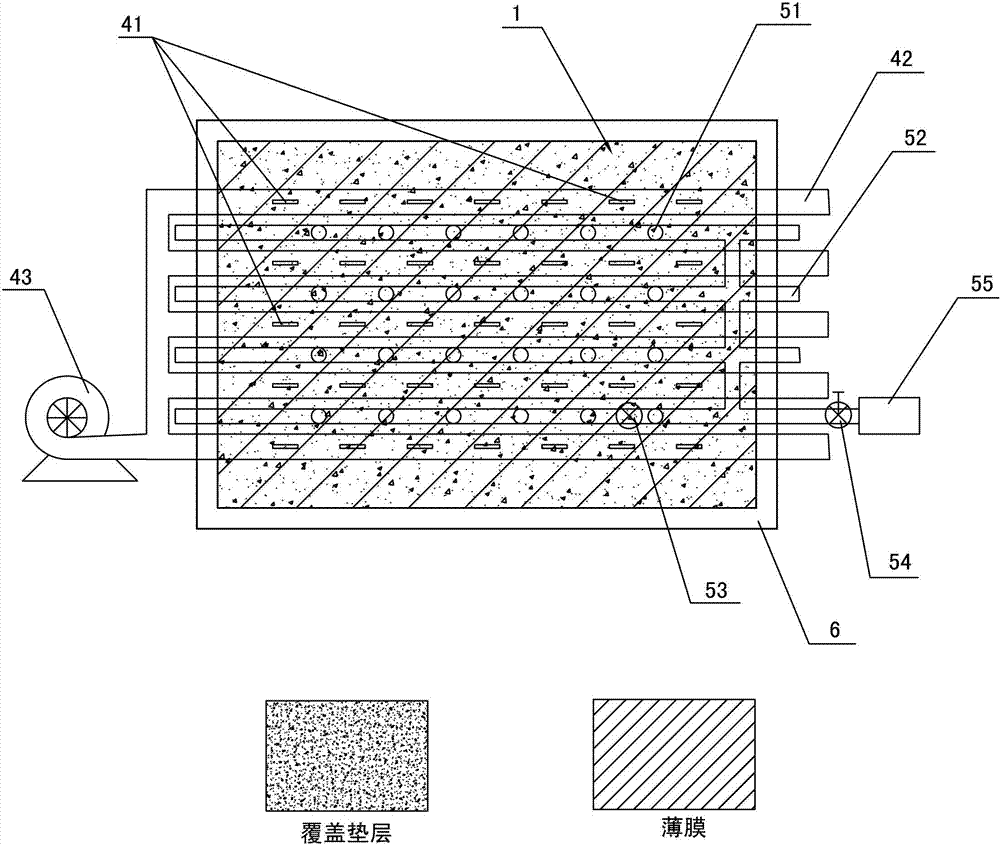

[0027] ① As shown in the figure, build a vacuum drainage system and a grouting system in the soft soil foundation 1 to be treated, and then lay a layer of covering cushion 2 on the surface of the soft soil foundation 1 to be treated, and then cover the cushion 2 Cover with a layer of film3. The specific process of this step is:

[0028] ①-1. Construction of the vacuum drainage system: as shown in the figure, multiple rows of vertical drainage boards are inserted in the soft ground 1 to be treated, and each row of vertical drainage boards includes a plurality of vertical drainage boards 41; A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com