Double-source heat pump water heater and double-source heat pump heat cascade hot water application all-in-one machine

A dual-source heat pump and water heater technology, which is applied to heat pumps, refrigerators, fluid heaters, etc., can solve the problems of no dual-source heat pump, no consideration and solution to the influence of waste water and hot water in bathing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

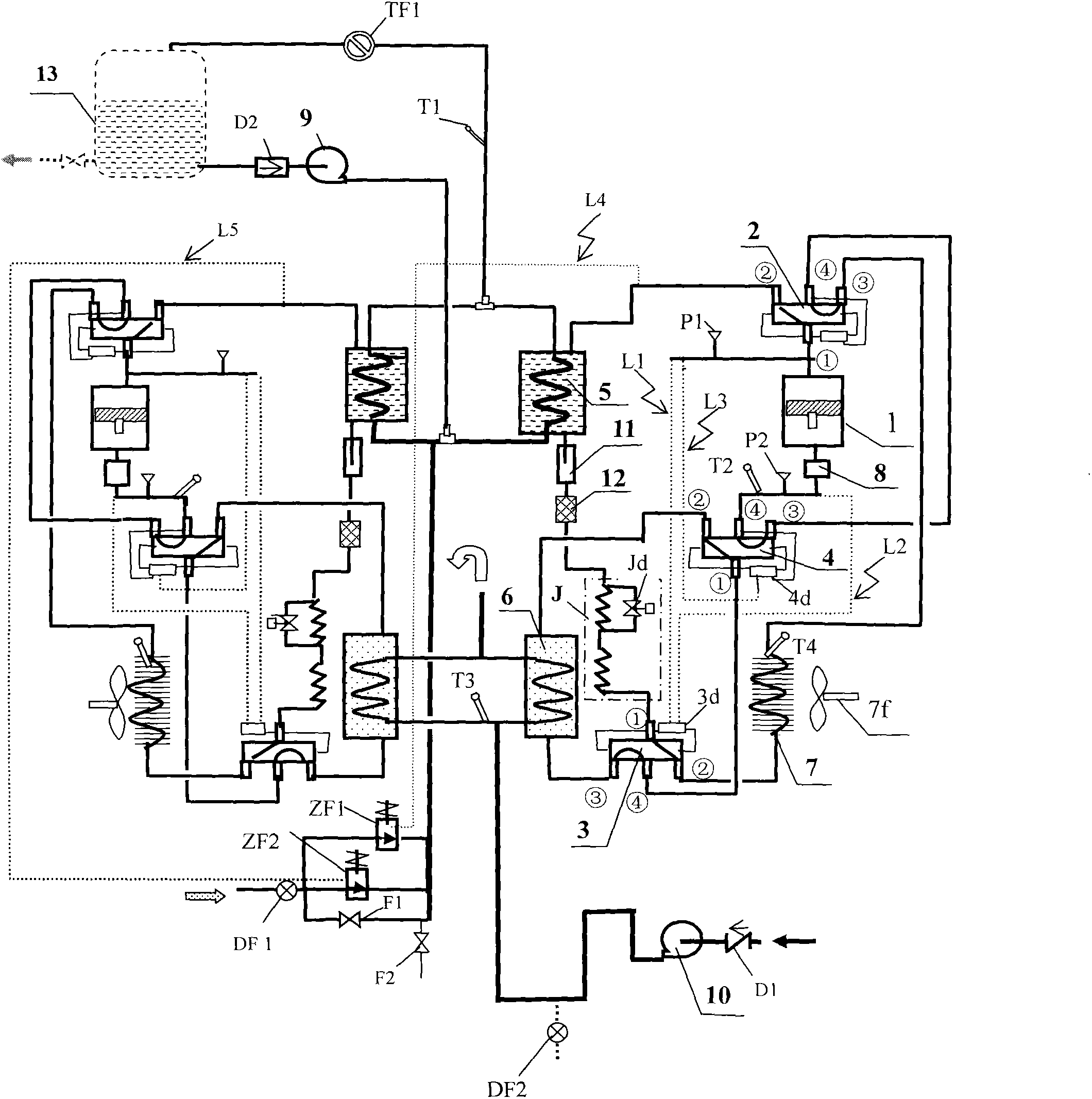

[0075]Embodiment 1. The dual-source heat pump water heater in Embodiment 1 of the present invention adopts the first refrigerant circuit system structure, and has two sets of refrigerant circuit systems with three four-way valves and six separate cycles. The water inlet control of the thermal system and the water inlet and drainage control of the water source heat exchange system are common.

[0076] The basic structure and working principle of the dual-source heat pump water heater of embodiment 1, by figure 1 illustrate.

[0077] figure 1 There are two sets of refrigerant circuit systems in the figure 1 The system in the middle right half is taken as an example to illustrate the structure of the refrigerant circuit system and the working principle of the whole machine. The refrigerant system includes: compressor 1, first four-way valve 2, second four-way valve 3, third four-way valve 4, hot water heat exchanger 5, water source heat exchanger 6, air source heat exchange D...

Embodiment 2

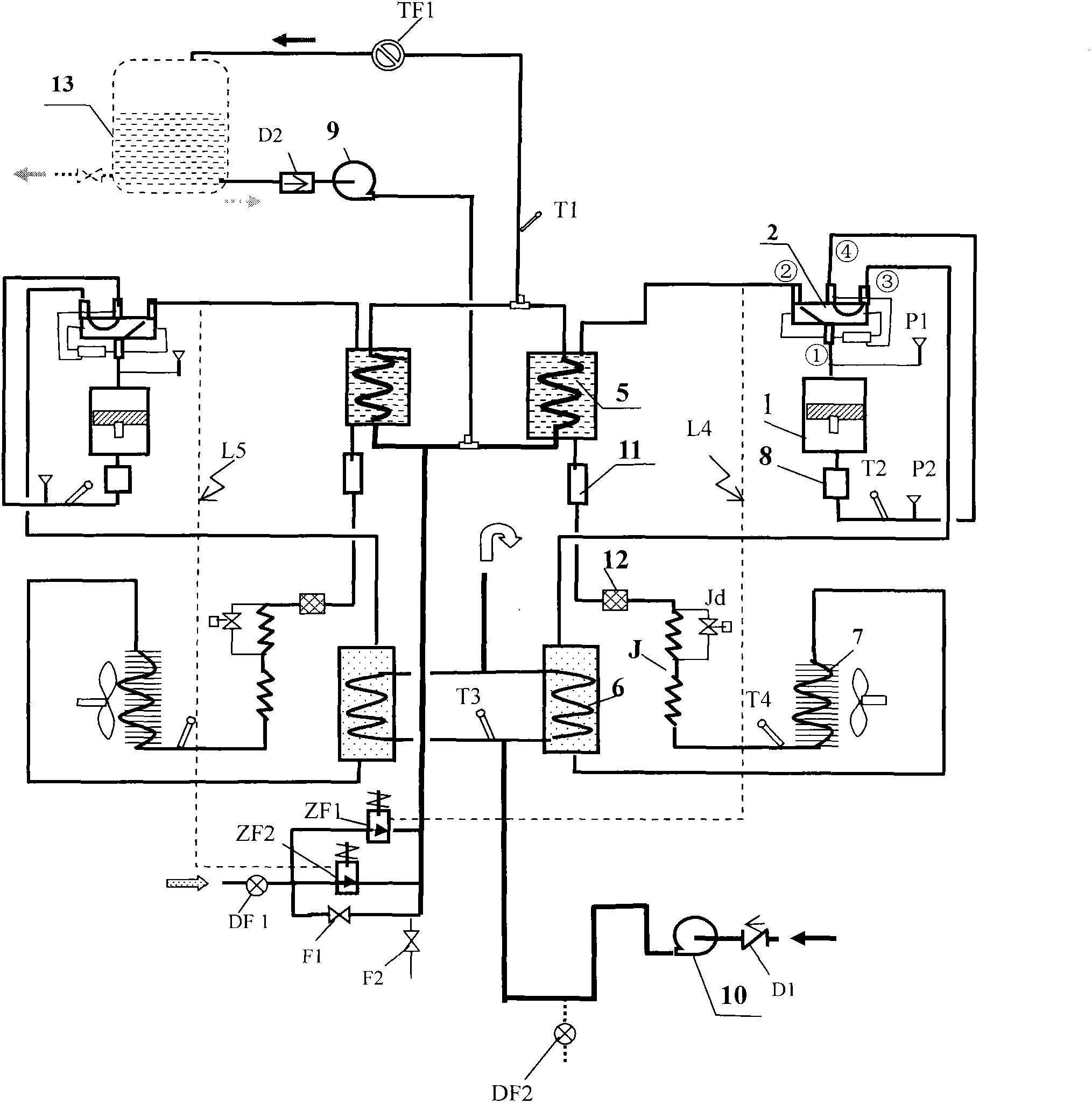

[0098] Embodiment 2. The dual-source heat pump water heater in Embodiment 2 of the present invention adopts the second refrigerant circuit system structure, and has two sets of refrigerant circuit systems. The water inlet control of the shared heat exchange system and the water source heat exchange system are shared. The water inlet and drainage control system; the hot water heating system of embodiment 2, the composition of the water source heat exchange system and the throttling device of the refrigeration circuit are all the same as those of embodiment 1.

[0099] The basic structure and working principle of the dual-source heat pump water heater of embodiment 2, by figure 2 illustrate.

[0100] For the structure and connection method of the single four-way valve air source + water source in series with two discrete circulating refrigerant circuit systems in embodiment 2, see figure 2 The right half shows: the exhaust port of compressor 1 is connected to the first port ①...

Embodiment 3

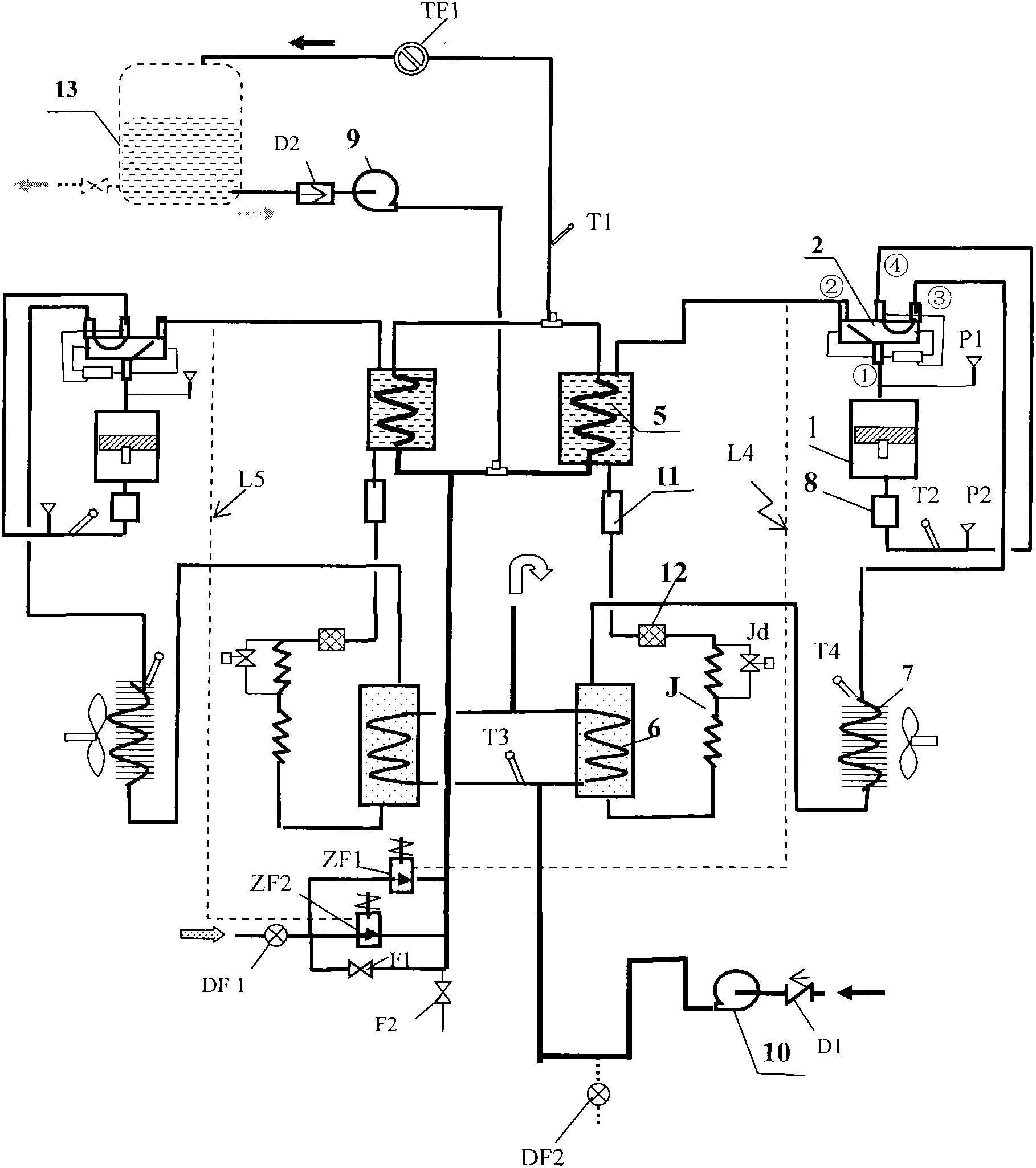

[0106] Embodiment 3. The dual-source heat pump hot water machine in Embodiment 3 of the present invention adopts the third refrigerant circuit system structure, and has two sets of refrigerant circuit systems. The water inlet control of the shared heat exchange system and the water source heat exchange system are shared. The water inlet and drainage control system; the hot water heating system of embodiment 3, the composition of the water source heat exchange system and the throttling device of the refrigeration circuit are all the same as those of embodiment 1.

[0107] The basic structure and working principle of the dual-source heat pump water heater of embodiment 3, by image 3 illustrate.

[0108] Embodiment 3 has two sets of the single four-way valve water source + air source in series with two discrete cycle refrigerant loop systems, see image 3 , the connection method is: the exhaust port of the compressor 1 is connected to the first port ① of the four-way valve 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com