Radio frequency (RF) laterally diffused metal oxide semiconductor (LDMOS) component and manufacture method

A manufacturing method and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of snapback effect, failure of device voltage resistance, large base resistance, etc., to improve the return point voltage, The effect of reducing series resistance and avoiding device burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

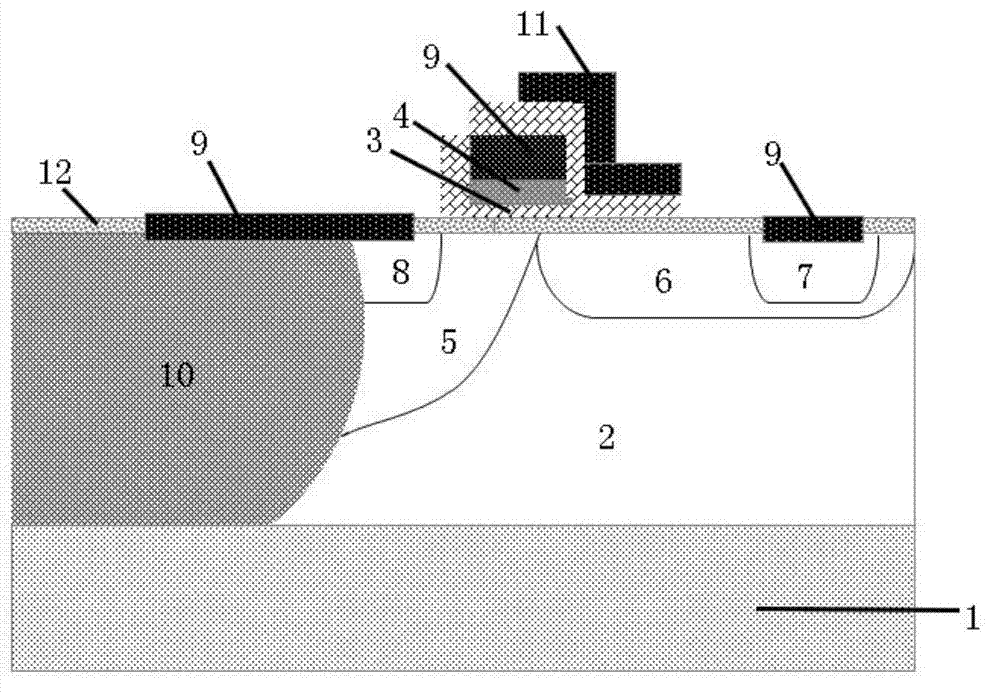

[0043] The structure of RFLDMOS device described in the present invention is as Figure 13 Shown:

[0044] On the P-type silicon substrate 311, there is a lightly doped P-type epitaxy 312;

[0045] In the lightly doped P-type epitaxy 312, there is an N-type lightly doped drain drift region 317 and a P-type channel region 316 in contact with it;

[0046] The N-type lightly doped drain drift region 317 includes the drain region 321 of the RFLDMOS device, and the surface of the drain region 321 has a metal silicide 319 leading to the drain of the RFLDMOS device;

[0047] The P-type channel region 316 includes a heavily doped P-type channel connection region 322 and a heavily doped N-type region 320 abutting against it. The heavily doped N-type region 320 is the RFLDMOS device. source area;

[0048] The surface of the heavily doped P-type channel connection region 322 and the source region 320 of the RFLDMOS is covered with a layer of metal silicide 319 leading to the source of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com