Non-aqueous electrolyte rechargeable battery

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, secondary batteries, battery electrodes, etc., can solve the problems of poor dispersion of carbon conductive agents and the inability to fully exert the performance of active materials, etc., to improve output power The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

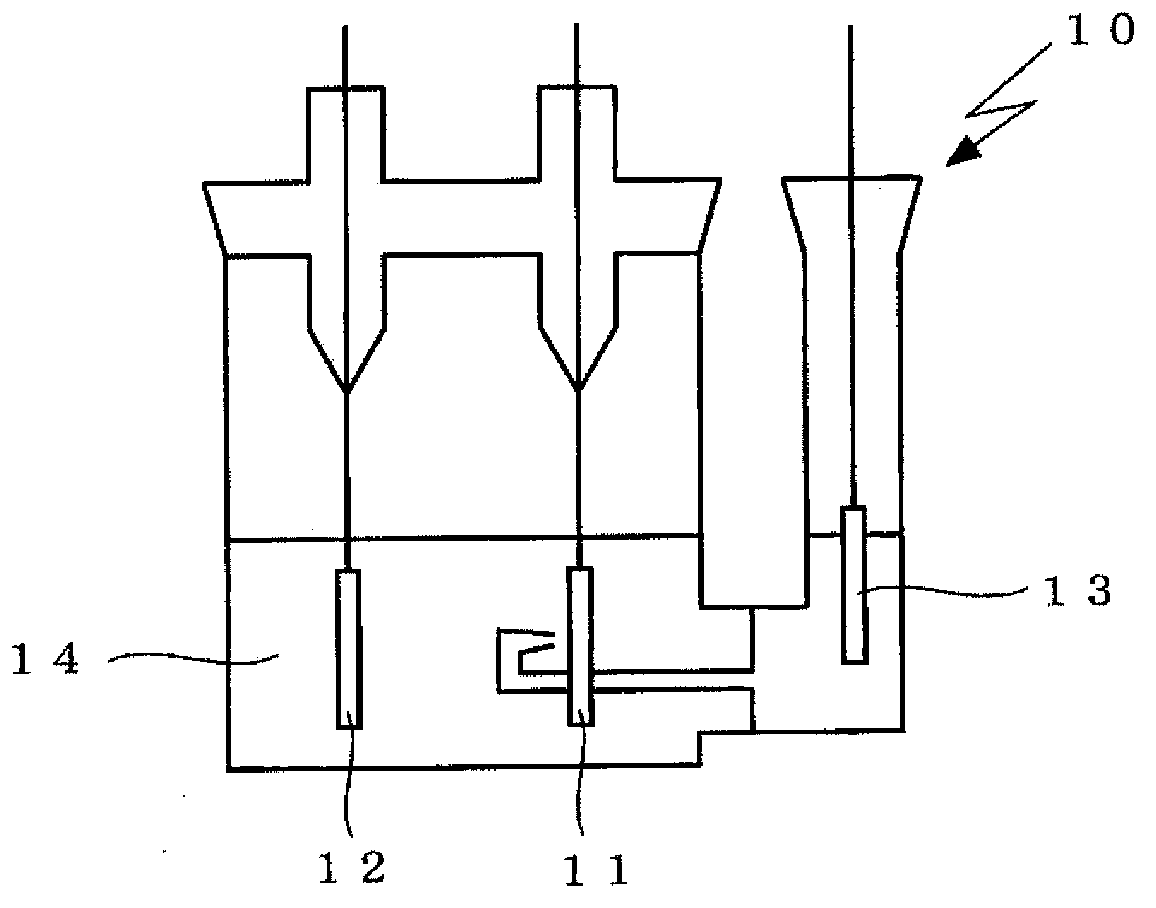

Image

Examples

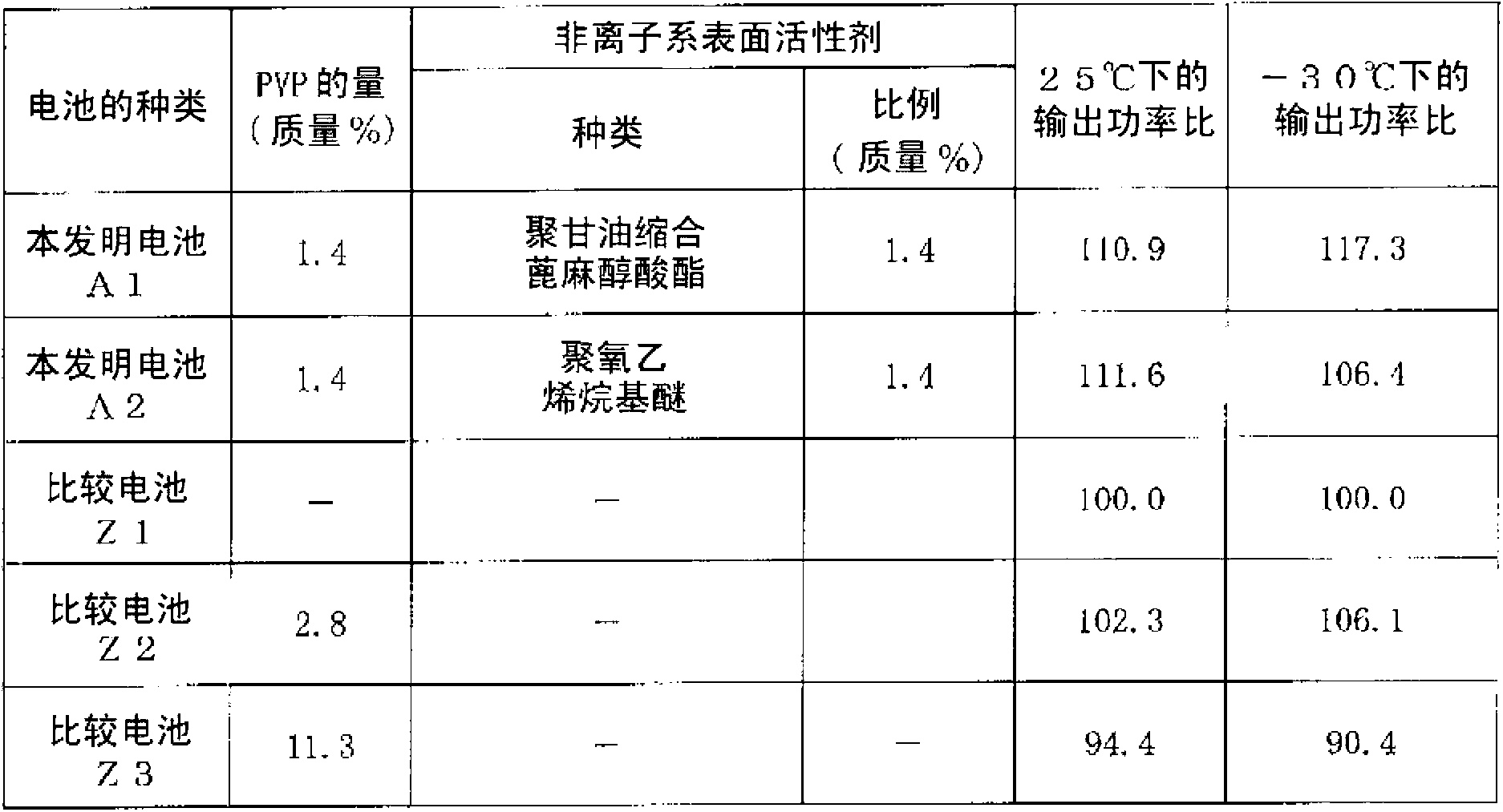

Embodiment 1

[0066] The battery shown in the above detailed description was used.

[0067] The battery thus manufactured is hereinafter referred to as battery A1 of the present invention.

Embodiment 2

[0069] A test cell was produced in the same manner as in Example 1 above, except that polyoxyethylene alkyl ether (LEOCOL SC-70 manufactured by Lion Corporation) was used as the nonionic surfactant.

[0070] The battery thus manufactured is hereinafter referred to as the battery A2 of the present invention.

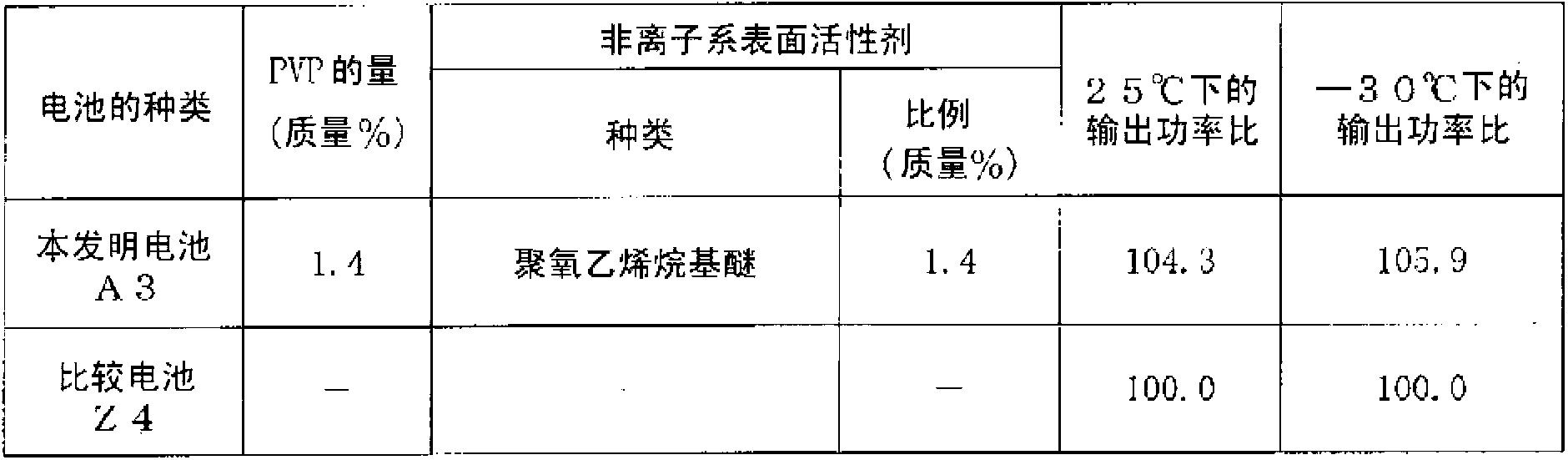

Embodiment 3

[0072] In addition to using furnace black as carbon conductive agent, LiNi 0.5 co 0.2 mn 0.3 o 2 Except for the positive electrode active material, a test cell was produced in the same manner as in Example 2 above.

[0073] The battery thus manufactured is hereinafter referred to as the battery A3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com