Lithium secondary battery

A lithium secondary battery and current collector technology, applied in the direction of secondary batteries, lithium storage batteries, battery electrodes, etc., to achieve the effects of small swelling, good charge-discharge cycle characteristics, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

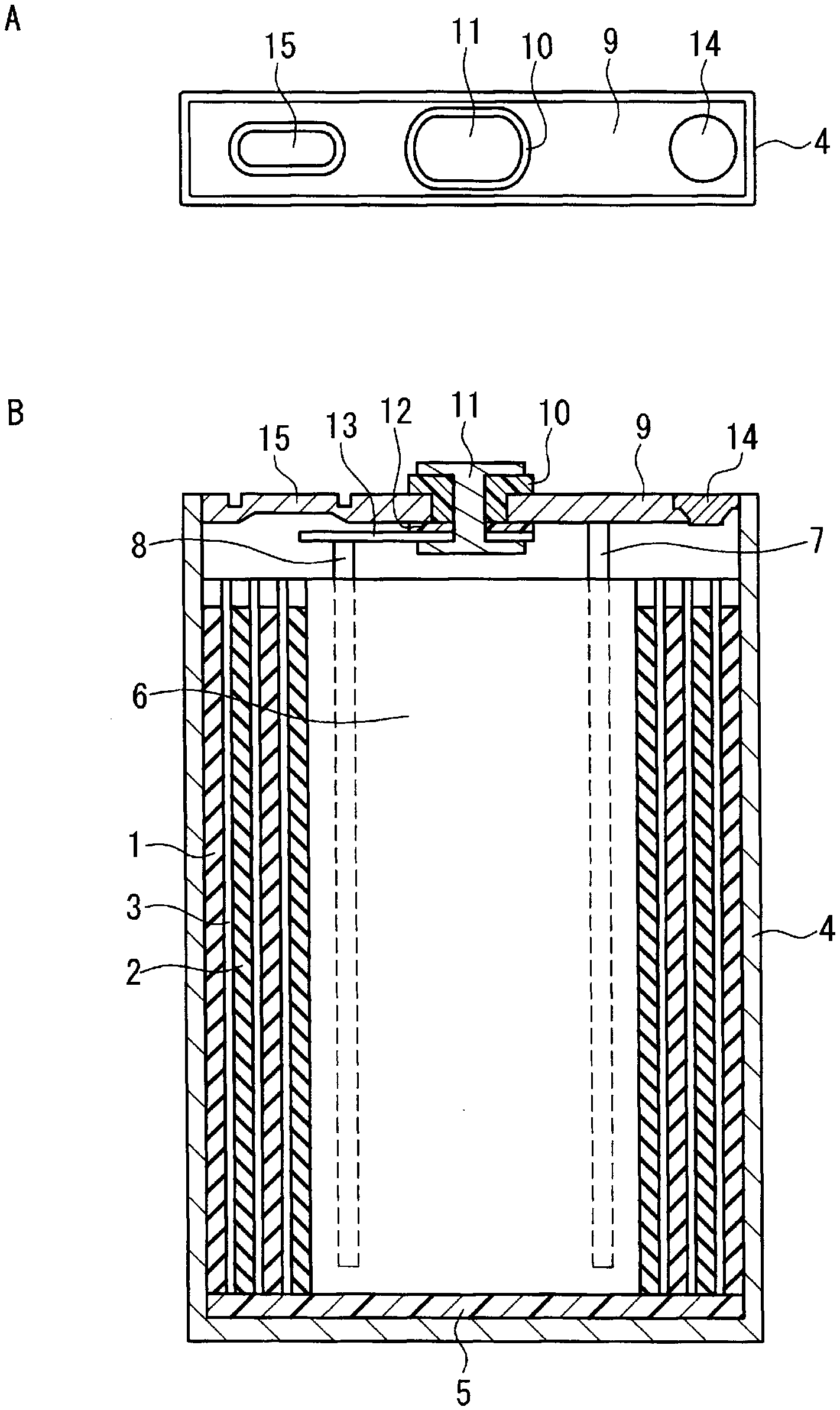

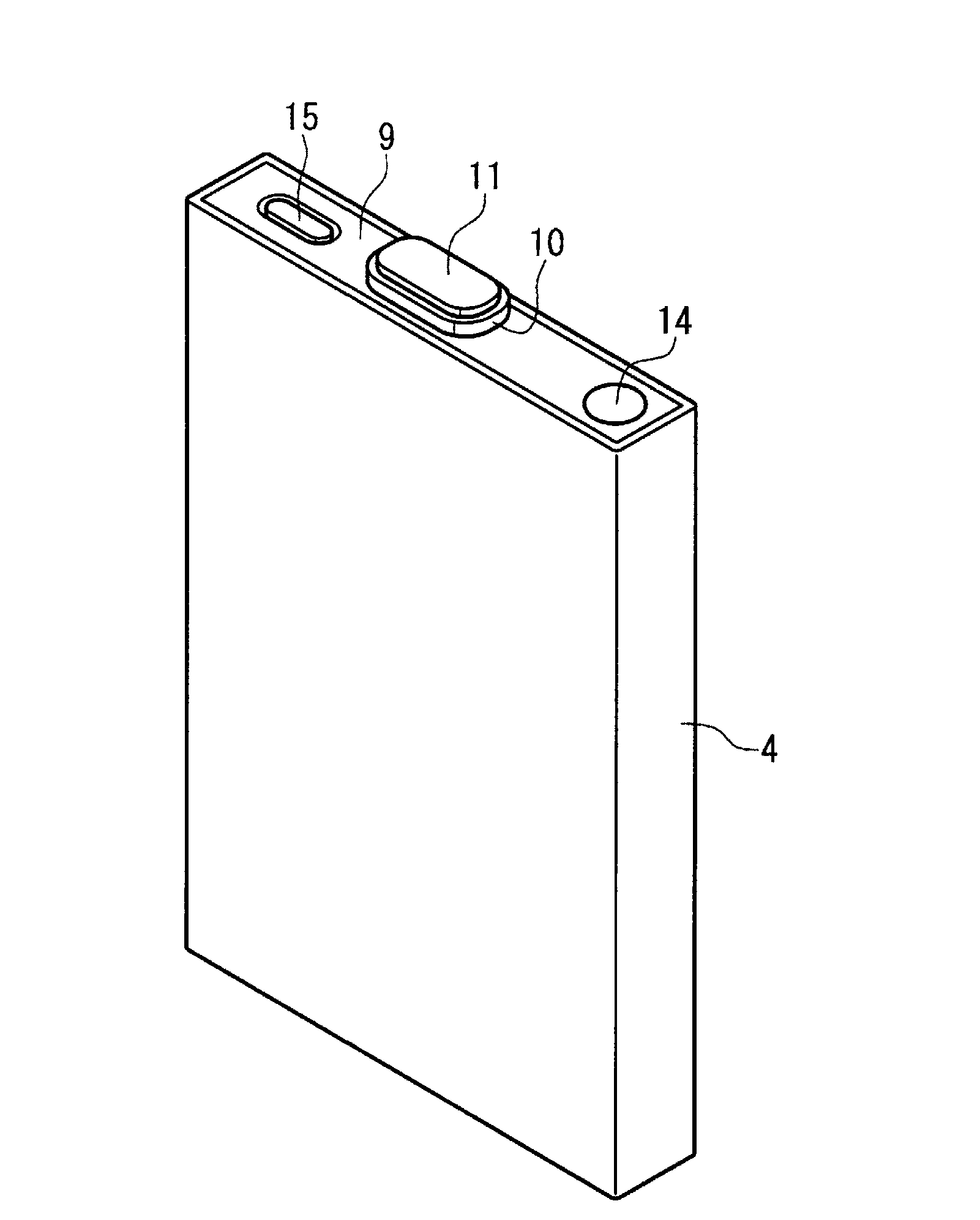

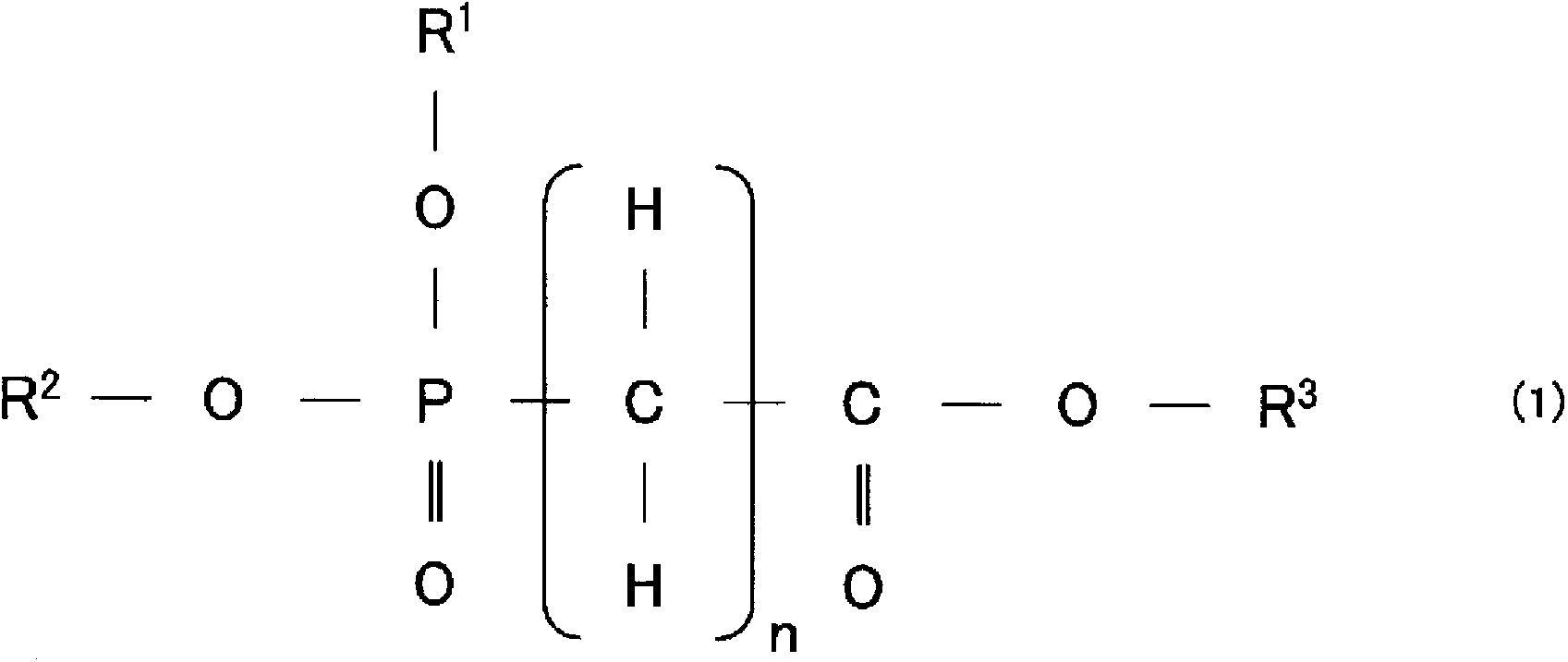

[0034] The first lithium secondary battery of the present invention includes a positive electrode, a negative electrode, a nonaqueous electrolytic solution, and a separator. In addition, the above-mentioned positive electrode includes a current collector and a positive electrode mixture layer formed on the above-mentioned current collector, the above-mentioned positive electrode mixture layer contains a positive electrode active material, and the above-mentioned positive electrode active material contains a first lithium-containing composite oxide containing lithium and nickel. The molar ratio of the nickel to the lithium in the entire amount of the first lithium-containing composite oxide is 0.05 to 1.05. Moreover, the said non-aqueous electrolytic solution contains 0.5-20 mass % of the phosphonoacetate compound represented by following general formula (1).

[0035]

[0036] In the above general formula (1), R 1 , R 2 and R 3 Each independently represents an alkyl group...

Embodiment 1-1

[0217]

[0218] Aqueous ammonia whose pH was adjusted to about 12 by the addition of sodium hydroxide was added to the reaction vessel, and while it was vigorously stirred, the 3 / min, 6.6cm 3 The ratio of 2.4mol / dm / min is added dropwise using a quantitative pump 3 , 0.8mol / dm 3 , 0.8mol / dm 3The concentration contains a mixed aqueous solution of nickel sulfate, cobalt sulfate and manganese sulfate, and ammonia water at a concentration of 25% by mass to synthesize a co-precipitation compound (spherical co-precipitation compound) of Ni, Co and Mn. At this time, the temperature of the reaction solution was maintained at 50°C. In addition, in order to maintain the pH of the reaction solution at around 12, a 6.4mol / dm 3 Concentration of sodium hydroxide aqueous solution is added dropwise. In addition, in order to react in an inert atmosphere, 1dm 3 Nitrogen is blown in at a flow rate of / min.

[0219] The above coprecipitated compound was washed with water, filtered and drie...

Embodiment 1-2

[0241] A lithium secondary battery was produced in the same manner as in Example 1-1, except that triethylphosphonoacetate was added to the non-aqueous electrolytic solution in such an amount that the concentration became 0.5% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com