Preparation and quality control method of gangsong general flavones

A quality control method and a technology of total flavonoids, applied to medical preparations containing active ingredients, measuring devices, pharmaceutical formulas, etc., can solve the problem of wasting medicinal resources, pine pine is not used much, and pine pine is not fully developed Use and other problems to achieve good application prospects, fast separation speed, and improve market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

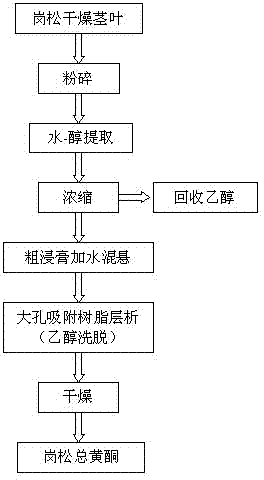

Method used

Image

Examples

Embodiment 1

[0039]Take 1000g of dry stems and leaves of Pinus pine, add 10L of 30% ethanol, heat and reflux for extraction 3 times, each time for 1 hour, combine the extracts, filter, and recover the filtrate under reduced pressure until it has no ethanol smell, add water to dissolve to 3000mL, shake well to obtain Concentration is 0.33g of crude drug amount / mL of Gangsong pine extract. Take 150mL of the treated AB-8 macroporous adsorption resin, wet-pack the column, absorb 300mL Pinus pine extract at a sample flow rate of 0.5BV / h, and elute with 2BV of water until the eluent is basically clear. Discard the water eluate, elute with 5BV 50% ethanol at a flow rate of 2BV / h, collect 5BV eluate, recover ethanol under reduced pressure, concentrate to dryness, and vacuum dry at 60°C to obtain the total flavonoids extract of Pinus pine, and determine , Calculated, the total flavonoid content is 52.3%.

Embodiment 2

[0041] Take 1000g of dry stems and leaves of Pinus pine, add 15L of 50% ethanol, heat and reflux for extraction 3 times, 2 hours each time, combine the extracts, filter, and recover the filtrate under reduced pressure until it has no ethanol smell, add water to dissolve to 2000mL, shake well, and get The concentration is 0.5g crude drug amount / mL Gangsong pine extract. Take 100mL of D101 macroporous adsorption resin that has been treated, and wet-pack the column. Adsorb 400mL of Pinus pine extract at a sample flow rate of 1BV / h, and elute with 2BV of water until the eluent is basically clear, and then eluted with water. The liquid was discarded, eluted with 6BV 70% ethanol at a flow rate of 3BV / h, collected 6BV eluate, recovered ethanol under reduced pressure, concentrated to dryness, and dried in vacuum at 60°C to obtain the total flavonoids extract of Pinus pine, determined, calculated, The total flavonoid content is 51.1%.

Embodiment 3

[0043] Take 1000g of dry stems and leaves of Pinus pine, add 15L of 70% ethanol, heat and reflux for extraction 3 times, each time for 3 hours, combine the extracts, filter, and recover the filtrate under reduced pressure until it has no ethanol smell, add water to dissolve to 1250mL, shake well to obtain The concentration is 0.8 g of crude drug / mL extract of Pinus pine. Take 100mL of the treated AB-8 macroporous adsorption resin, and wet-pack the column. Adsorb 500mL of Pinus pine extract at a sample flow rate of 2BV / h, and elute with 2BV of water until the eluent is basically clear. Discard the eluate, elute with 10BV of 50% ethanol at a flow rate of 5BV / h, collect 8BV of eluate, recover ethanol under reduced pressure, concentrate to dryness, and dry under vacuum at 60°C to obtain the total flavonoids extract of Pinus pine, determined, Calculated, the total flavonoid content is 54.0%.

[0044] Quality control method of total flavonoids of Gangpine:

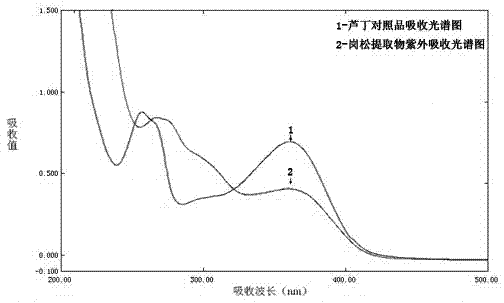

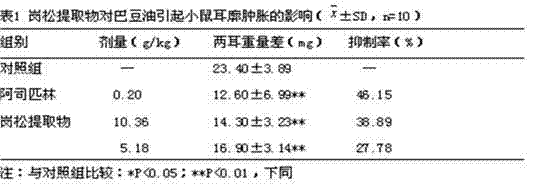

[0045] TLC identificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com