Supergravity device for rapidly dissolving water-soluble polymers

A water-soluble polymer and super-gravity technology, applied in the direction of dissolving, dissolving, mixing machines, etc., can solve the problems of low investment and operating costs, a large number of curing tanks, and low production efficiency, so as to save equipment investment and achieve good economic benefits. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

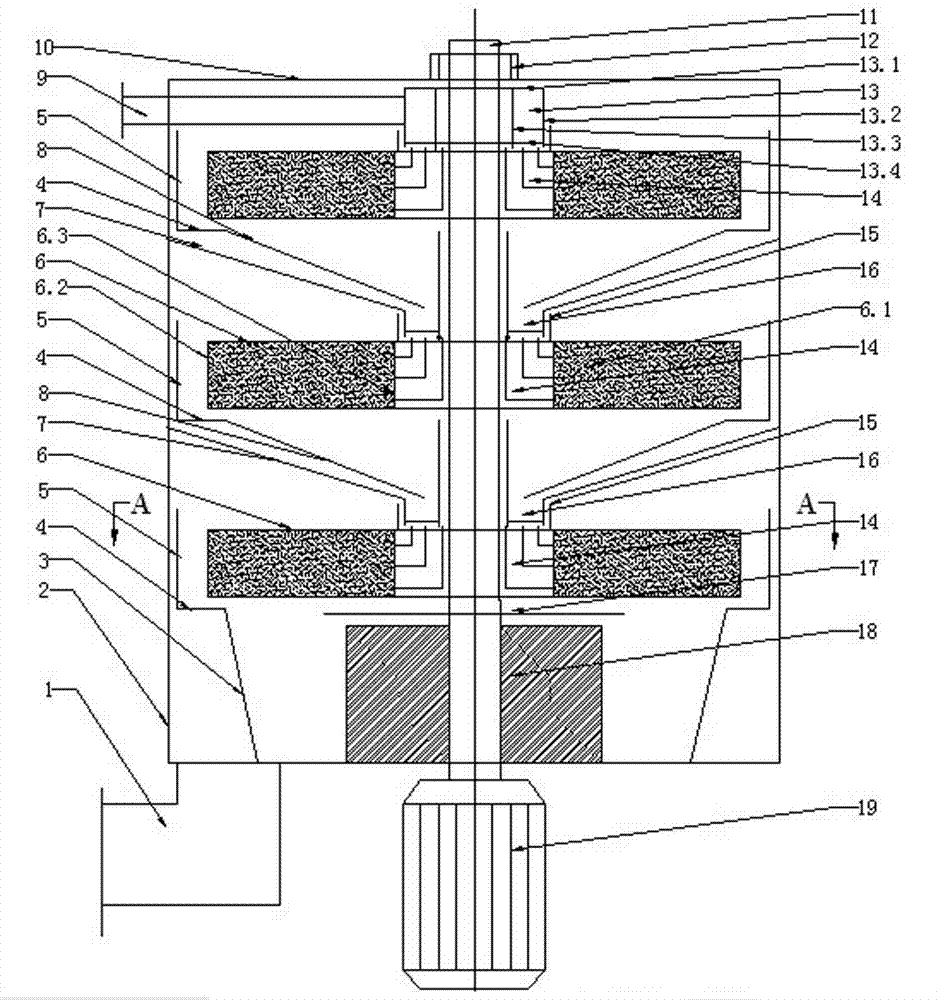

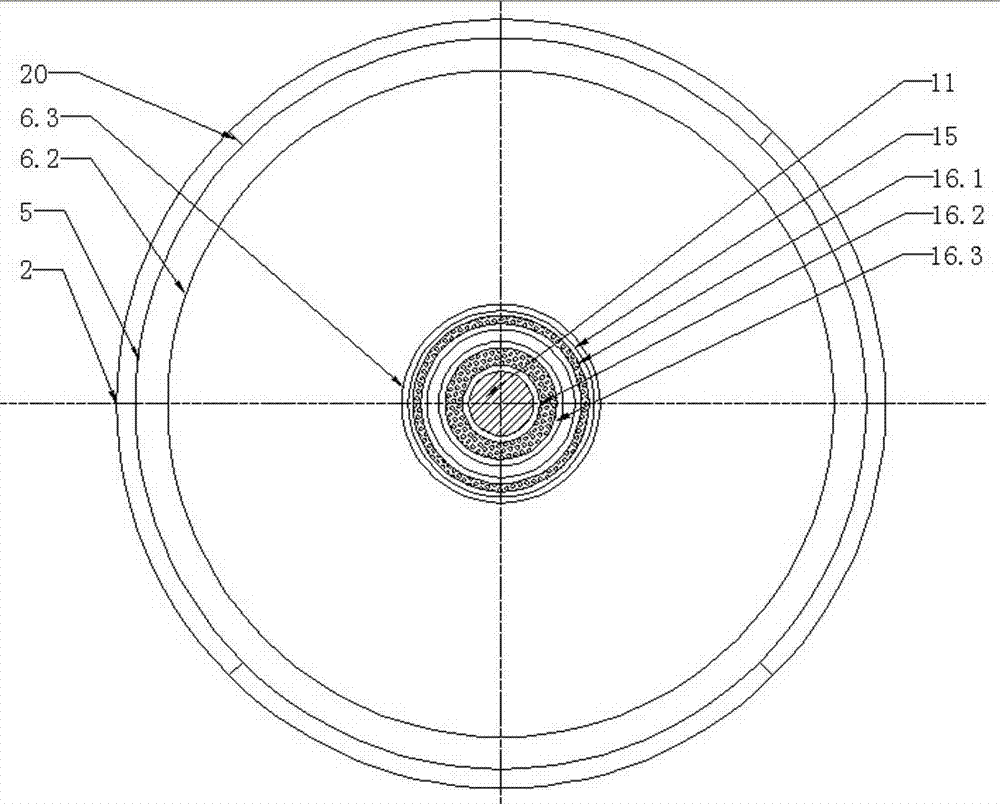

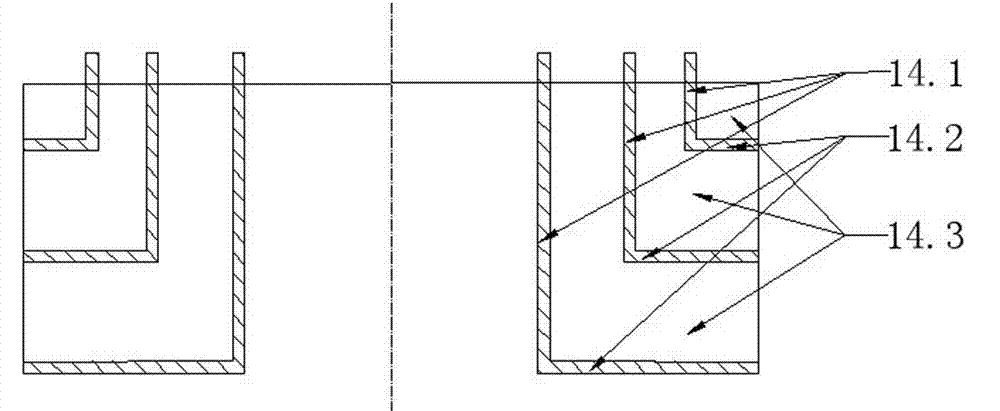

[0025] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0026] Water-soluble polymer rapid dissolution supergravity device, including shell 2, liquid inlet pipe 9, liquid outlet pipe 1, and a dissolving system with two or more stages from top to bottom (selected according to the difficulty of dissolving the polymer) series), the dissolution system includes a static distributor, a dynamic distributor, a rotor 6 and a diversion structure, the static distributor is arranged above the dynamic distributor, the dynamic distributor is fixed on the inner side of the rotor, and the diversion structure is arranged on the On the periphery of the rotor, the outlet at the lower end of the diversion structure of the upper dissolving system extends above the static distributor of the lower dissolving system. The diversion structure other than the final diversion structure also includes an outer diversion cylinder arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com