Synthesis method of Y type molecular sieve

A synthesis method and molecular sieve technology, which are applied in the directions of fajhedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of high production cost of molecular sieve, non-conformity, pollution discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Specifically, the synthetic method of Y-type molecular sieve of the present invention comprises the following steps:

[0020] (1) Mineral activation, uniformly mix low-silicon-aluminum ratio minerals and high-silicon mineral powders in proportion, the mixed minerals and sodium hydroxide solids are mixed and ground according to the mass ratio of 1:1 to 2.5:1, and then heated at 550°C to Roasting at 900°C to become synthetic raw materials; or mixing and grinding high-silicon minerals and low-silicon-aluminum ratio minerals with sodium hydroxide solid at a mass ratio of 1:1 to 2.5:1, and then roasting at 550°C to 900°C before mixing, As a synthetic raw material; or mix and grind low-silicon-aluminum ratio minerals and sodium hydroxide solids in a mass ratio of 1:1 to 1:2, then roast at 550 to 900°C, and then mix with high The silicon mineral is mixed as a synthetic raw material. After mixing, the mass ratio of the mineral mixture to the sodium hydroxide solid is 1:1 to 2.5...

Embodiment 1

[0034] Dissolve 27.2 grams (g) of sodium hydroxide solid (produced by Beijing Chemical Plant, with a purity of 99%) in 38 g of water, cool to room temperature, and set aside. Get 26.66g aluminum sulfate (molecular formula: Al 2 (SO 4 ) 3 18H 2 (0, Beijing Yili Fine Chemicals Co., Ltd., with a purity of 99%) was dissolved in 38 g of water, and the prepared aluminum sulfate solution was added to the sodium hydroxide solution to make a high-alkali sodium metaaluminate solution. With 85.26g sodium silicate (molecular formula: Na 2 SiO 3 9H 2 O, Beijing Modern Chemical Reagent Company, purity is 99%) is dissolved in 100g water, adds 72g silica sol (Beijing Red Star Soda Soda Factory, SiO 2 The content is 24.96%, Na 2 O content is 0.05%), stirring rapidly for 2 hours. Then add high alkali sodium metaaluminate solution under stirring condition, mix evenly, stir and age at 30° C. for 4 hours, and stand and age at room temperature for 2 days to prepare a directing agent solutio...

Embodiment 2

[0038] The preparation method of the directing agent is the same as in Example 1. Commercially available kaolin and diatomaceous earth were dried and pulverized into powder respectively. Weigh 38g of kaolin powder and 23g of diatomaceous earth powder, uniformly mix with 60g of sodium hydroxide solid, roast at 780°C for 5 hours, and set aside.

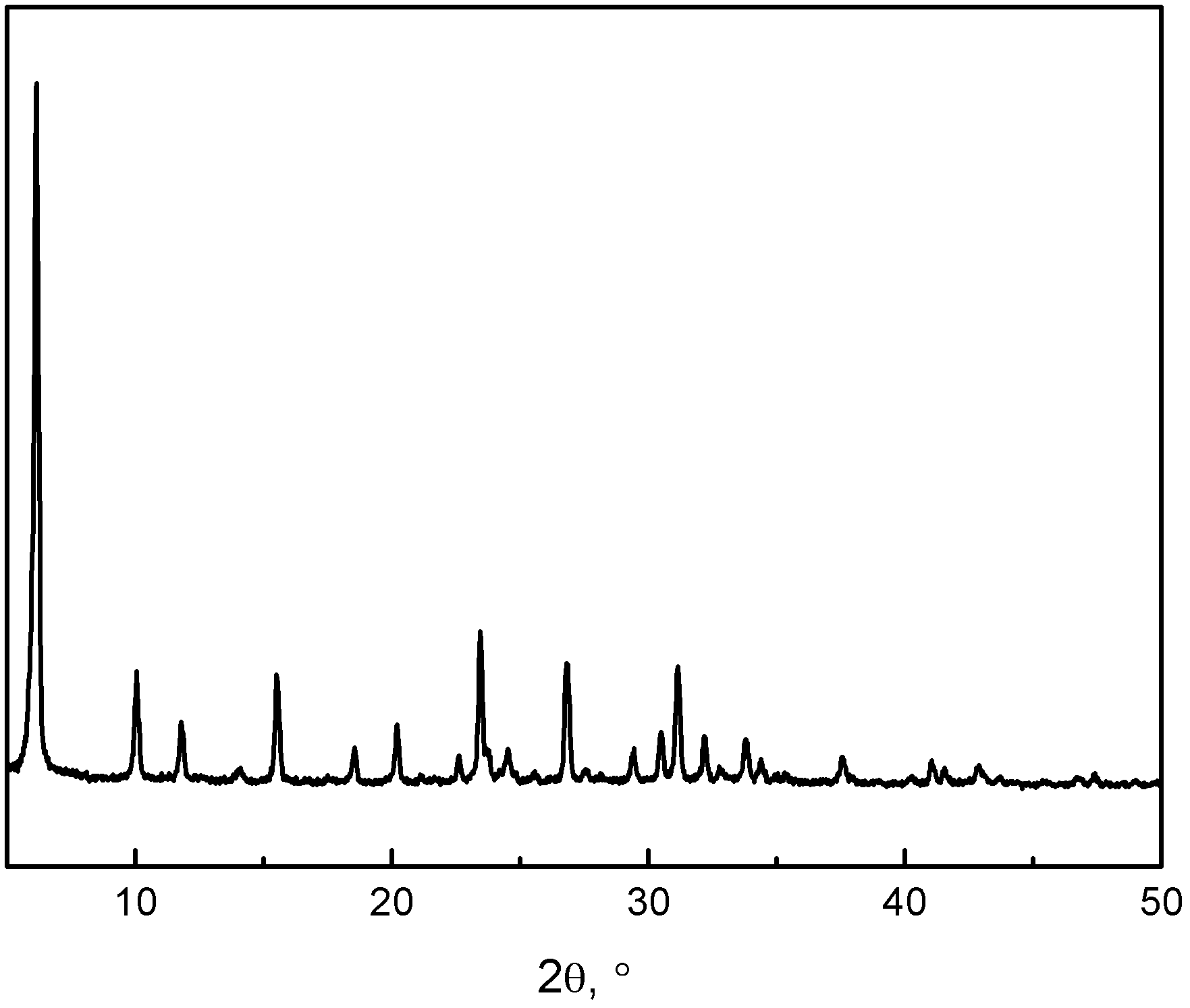

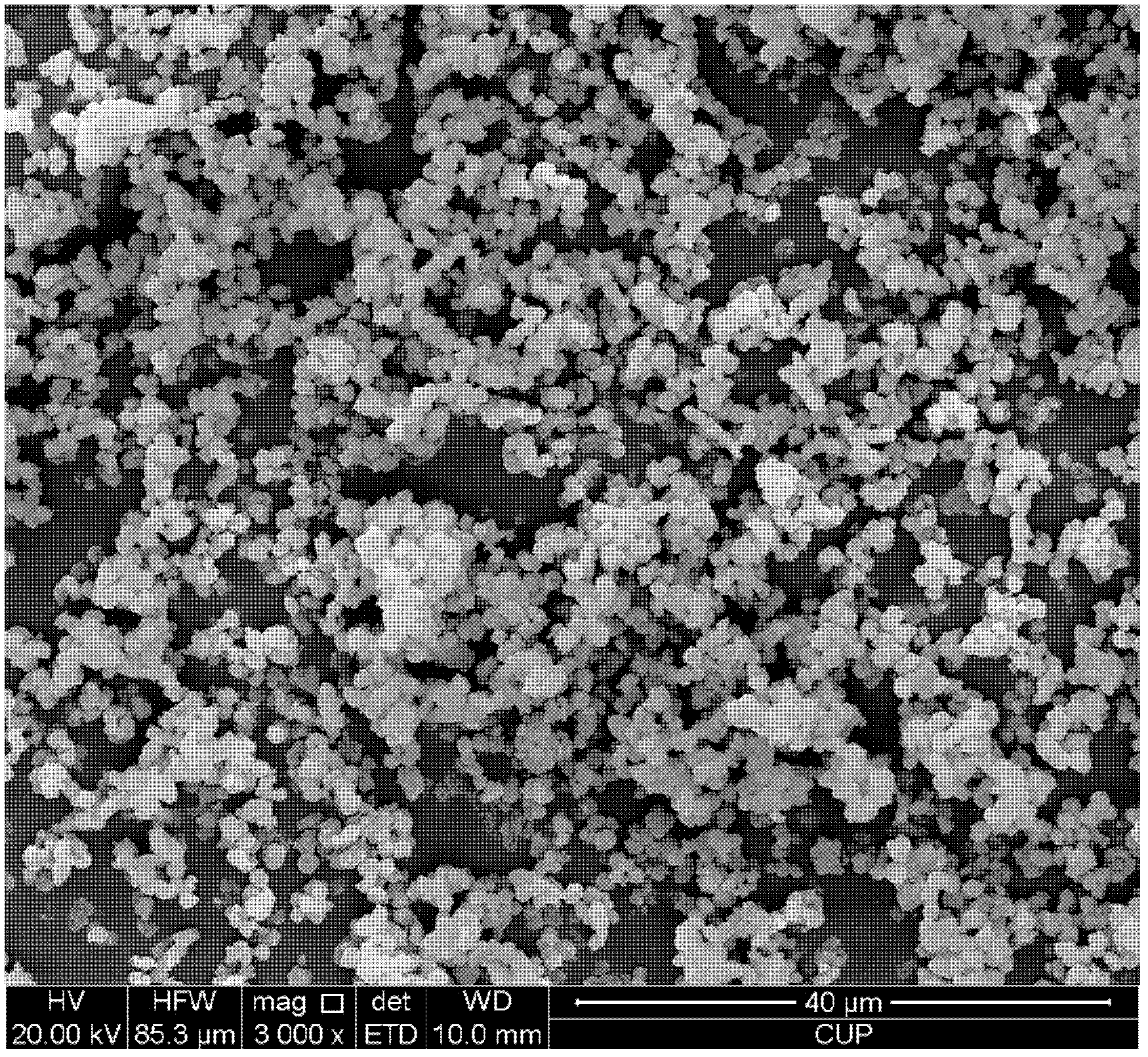

[0039] Weigh 6 g of the above calcined mineral powder, add 40 g of deionized water and 6.7 g of directing agent, and mix and stir at 60° C. for 14 hours. The mixed solution was poured into a polytetrafluoroethylene-lined stainless steel crystallization kettle, and the temperature was raised to 95° C. for static crystallization for 18 hours. After the crystallization is completed, cool and filter to remove the mother liquor, wash until the pH value is less than 10, and dry at 120° C. to obtain a crystallized product. As determined by XRD, its phase belongs to NaY molecular sieve, the relative crystallinity of Y-type molecular sieve in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com