Equipment and method for treating biomass bin type compost

A technology for processing equipment and biomass, which is applied in the treatment of biological organic parts, preparation of organic fertilizers, organic fertilizers, etc. Insect resistance, achieve zero emission and no pollution, and improve the effect of soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

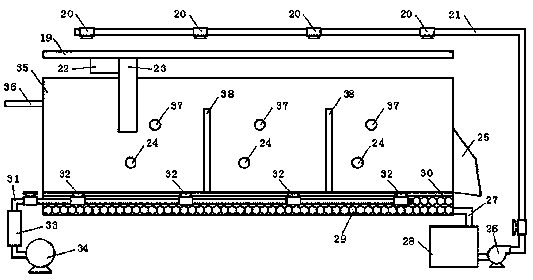

[0027] see figure 1, the biomass bin type composting treatment equipment includes a reaction bin 35; the reaction bin 35 is divided into several small reaction bins by a reaction bin partition 38; a temperature sensor 24 and a humidity sensor 37 are arranged in the reaction bin 35 One end of the reaction chamber 35 is provided with a feed platform 36, and the other end is provided with a discharge port 25; the top of the reaction chamber 35 is provided with a stirring hoist track 19, and the stirring hoist track 19 passes through the stirring hoist motor 22 It is connected with the stirring hoist 23 in the reaction chamber 35; the water inlet pipe 21 is also provided above the reaction chamber 35, and the water inlet pipe 21 is provided with a spray head 20; the bottom of the reaction chamber 35 is provided with a porous structure Filter layer 29; said percolation layer 29 is provided with a water outlet pipe 27 communicating with the reaction chamber 35, said water outlet pip...

Embodiment 2

[0029] A biomass composting treatment method based on the biomass bin type composting treatment equipment described in embodiment 1, comprising the steps of:

[0030] (1) Sorting, crushing, screening, batching, and mixing biomass into compost raw materials before composting; wherein, the length of the compost raw materials is 3-5 cm, and the carbon-nitrogen ratio in the compost raw materials is 20-30:1;

[0031] (2) Dilute the compound beneficial bacteria powder with water 50-100 times, and cultivate it at room temperature for 8-12 hours to obtain the bacteria liquid;

[0032] (3) Put the raw materials into the reaction chamber through the feeding platform, start the stirring and lifting motor to drive the stirring and lifting machine to work; at the same time start the water pump, and spray the bacteria liquid cultivated in step (2) on the raw materials through the water inlet pipe; through the humidity The sensor controls the humidity in the reaction chamber to be 45-60%; am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com