Antibacterial transparent polystyrene material and preparation method thereof

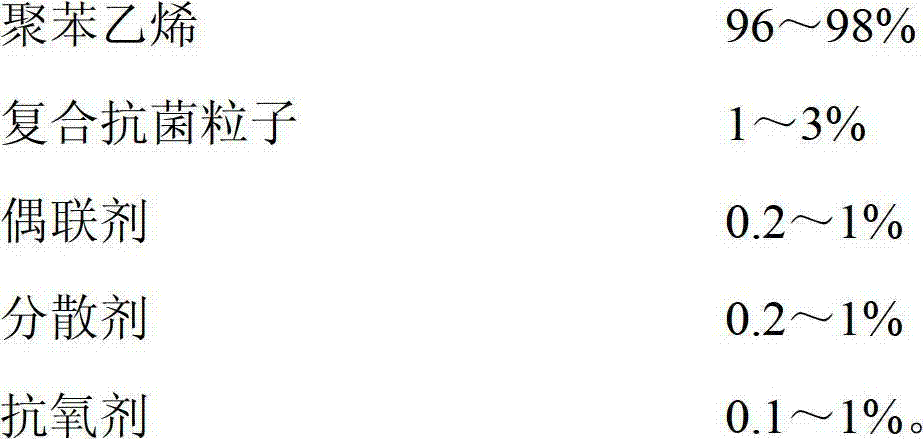

A technology of transparent polystyrene and polystyrene, applied in the field of polymer modification and processing, can solve the problems of weak antibacterial effect, difficulty in large-scale production, low light utilization rate, etc., achieve strong antibacterial effect and improve the degree of dispersion , Improve the effect of transparency and antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

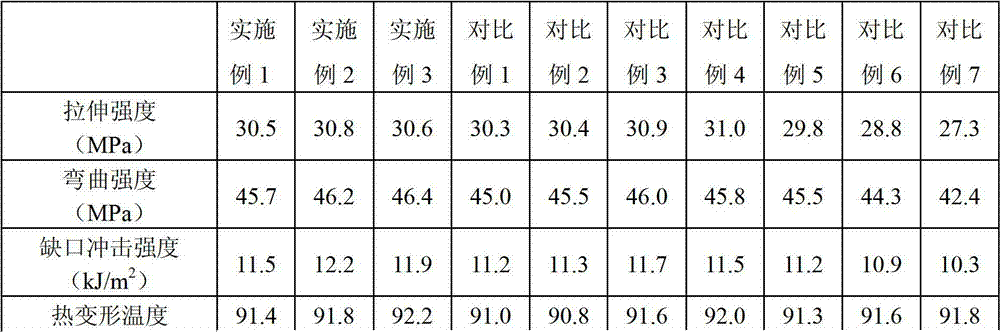

Examples

Embodiment Construction

[0023] In the following, the present invention will be further described in detail with reference to the embodiments:

[0024] In the composite material formulations of the Examples and Comparative Examples, the polystyrene selected HIPS produced by Yangzi BASF, with the trade name 466F. Nano TiO 2 The particles are anatase titanium dioxide, the particle size is less than or equal to 5nm, and the specific surface area is more than 200m 2 / g. Nano ZnO particles: produced by Shanghai Chemical Co., Ltd. The coupling agent is a silane coupling agent (KH550, commercially available). The dispersant is polyethylene wax (commercially available). The main antioxidant is Ciba 1010, the brand name is Irganox 1010, and the chemical name is tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester). The auxiliary antioxidant is 168 produced by Ciba, the brand name is Irgafos 168, and the chemical name is tris(2,4-di-tert-butylphenyl) phosphite.

[0025] Put the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com