Neodymium-ytterbium-codoped zirconia up-conversion luminescent material as well as preparation method and application thereof

A luminescent material, co-doping technology, applied in luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

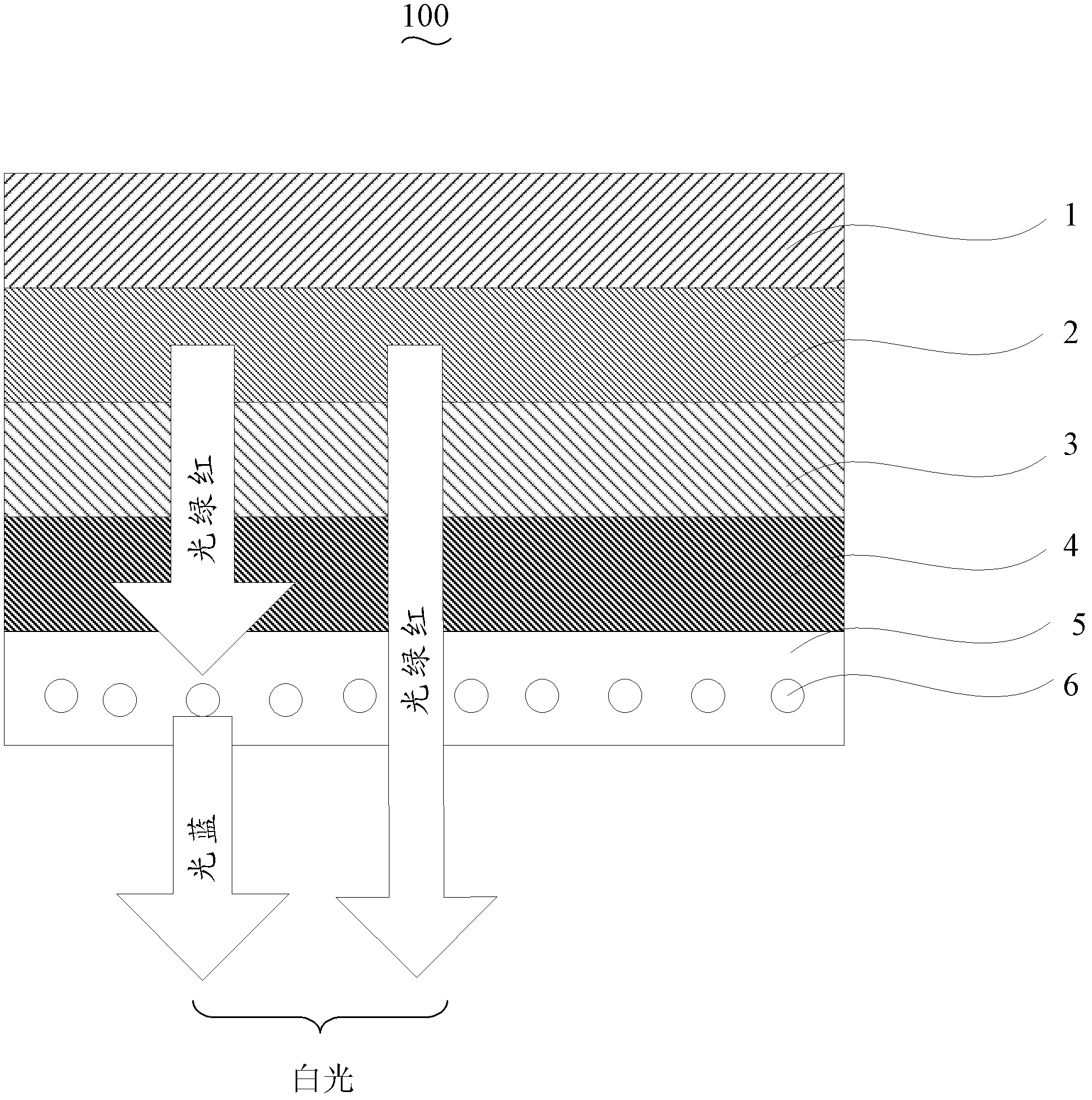

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned neodymium-ytterbium co-doped zirconia up-conversion luminescent material comprises the following steps:

[0024] Step S11, according to ZrO 2 :xYb 3+ ,yNd 3+ The stoichiometric ratio of each element weighs ZrO 2 , Yb 2 o 3 and Nd 2 o 3 Powder, where 0.01≤x≤0.1, 0.004≤y≤0.06.

[0025] In this step, preferably, x is 0.06 and y is 0.02.

[0026] It can be appreciated that ZrO can also be weighed in this step 2 , Yb 2 o 3 and Nd 2 o 3 powder and mix evenly, in which ZrO 2 , Yb 2 o 3 and Nd 2 o 3 The molar ratio is 89.6~93:0.5~5:0.2~3, preferably 92:3:1.

[0027] Step S13, mixing the powder weighed in step S11 evenly to obtain a precursor.

[0028] In this step, the powder is ground in a corundum bowl for 20 minutes to 60 minutes to obtain a homogeneously mixed precursor, preferably for 40 minutes.

[0029] Step S15, burning the precursor at 800° C. to 1000° C. for 0.5 hours to 5 hours, then cooling to 100° C....

Embodiment 1

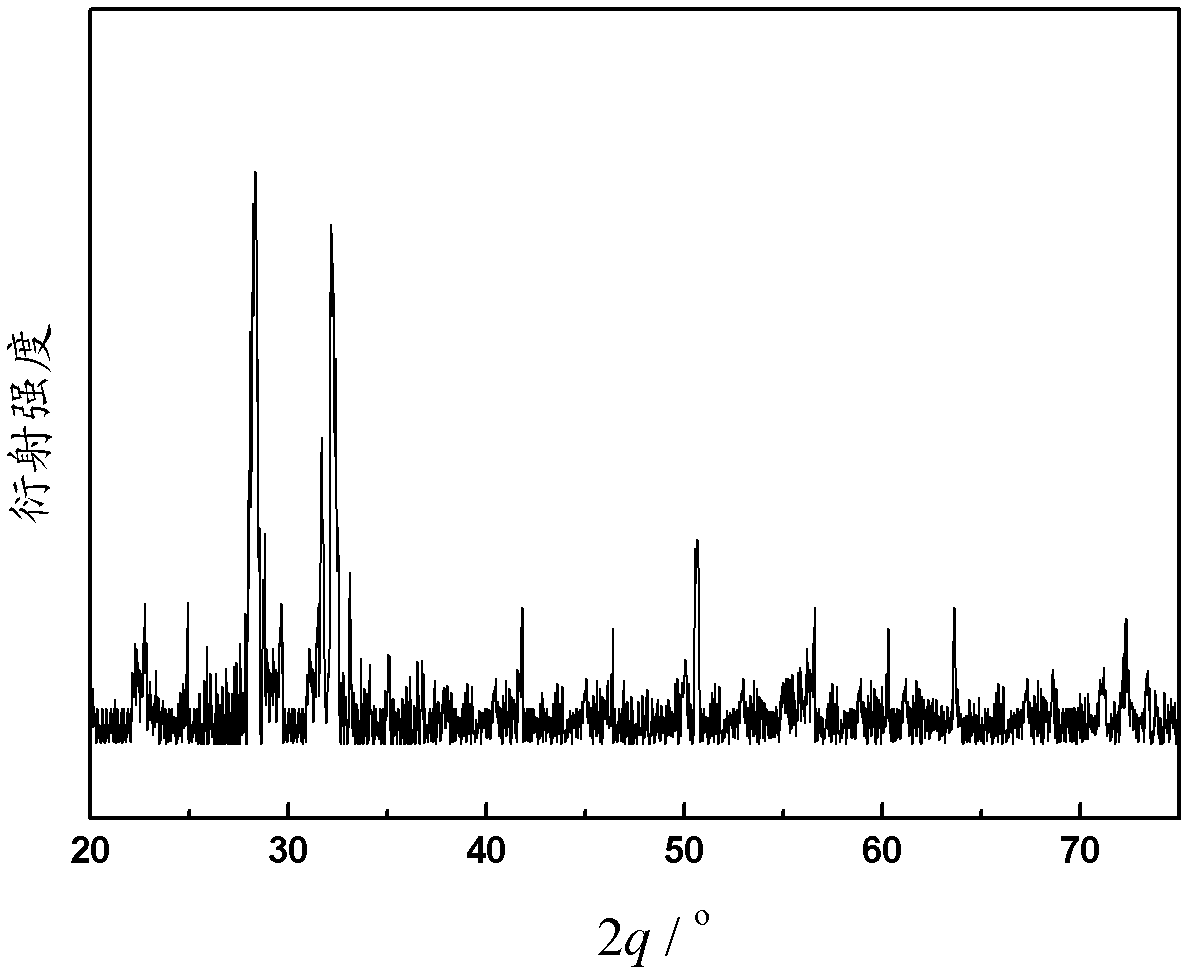

[0037] Choose powder with a purity of 99.99%, ZrO 2 , Yb 2 o 3 and Nd 2 o 3 The powder, the molar ratio of which is 92:3:1, was ground in a corundum mortar for 40 minutes to make it evenly mixed, then burned at 900°C for 3 hours, then cooled to 200°C for 2 hours, and then cooled to Take it out at room temperature to obtain bulk material, and after crushing, you can get the general chemical formula Zr 0.92 o 2 :0.06Yb 3+ , 0.02Nd3+ Up-converting phosphors.

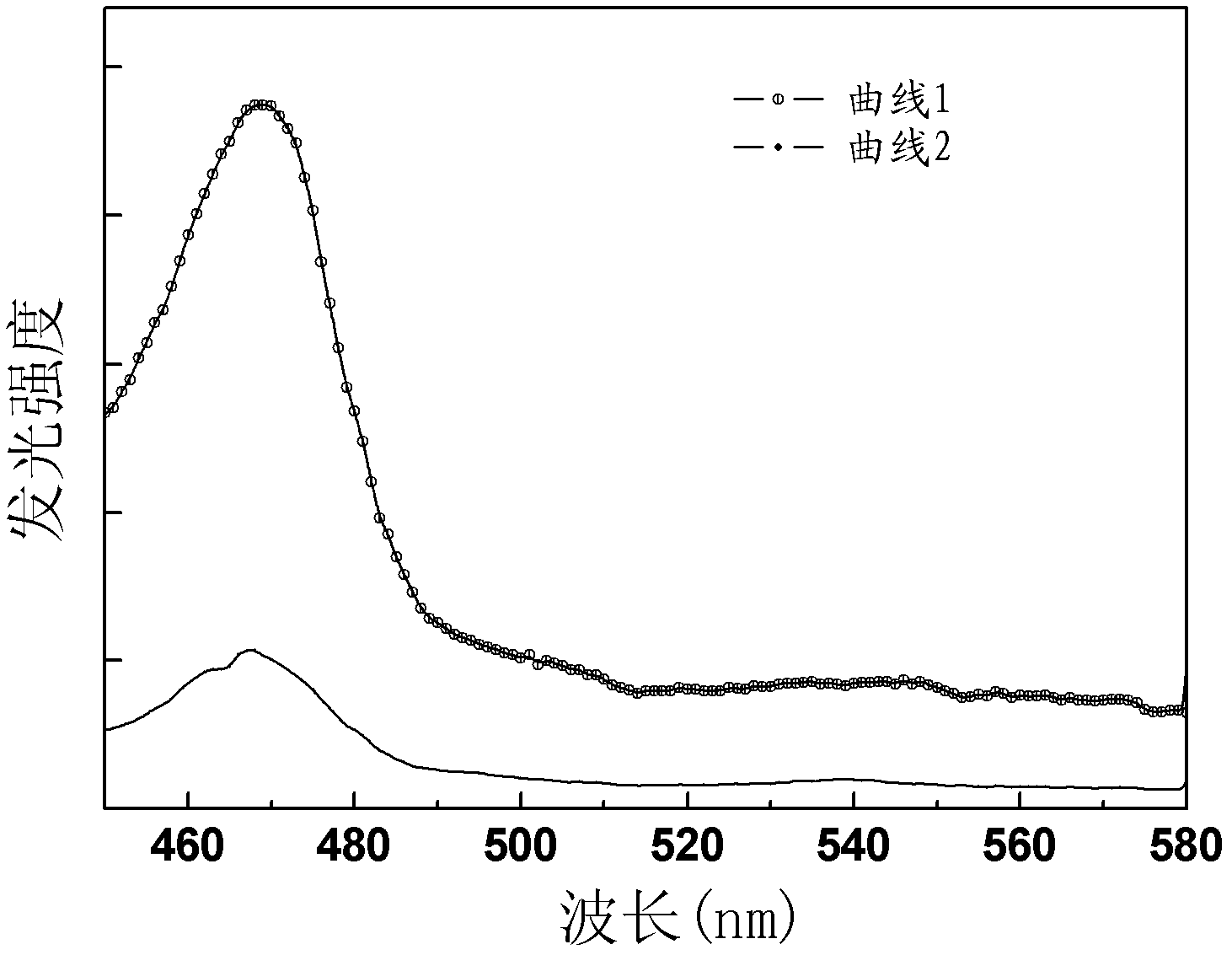

[0038] see figure 2 , figure 2 Shown are the obtained neodymium and ytterbium co-doped zirconia up-conversion luminescent materials and samples without ytterbium (the general chemical formula is Zr 0.98 o 2 :0.02Nd 3+ ) photoluminescence spectrum. Depend on figure 2 It can be seen that the excitation wavelength of the neodymium-ytterbium co-doped zirconia up-conversion luminescent material obtained in this embodiment is 586nm, and in the 469nm wavelength region, Nd 3+ ion 2 P 3 / 2 → 4 I 15 / 2 The transiti...

Embodiment 2

[0041] Choose powder with a purity of 99.99%, ZrO 2 , Yb 2 o 3 and Nd 2 o 3 The powder, the molar ratio of which is 93:0.5:3, was ground in a corundum mortar for 20 minutes to make it evenly mixed, then burned at 800°C for 0.5 hour, then cooled to 100°C and kept for 0.5 hour, and then cooled with the furnace to Take it out at room temperature to obtain bulk material, and after crushing, you can get the general chemical formula Zr 0.93 o 2 :0.01Yb 3+ , 0.06Nd 3+ up-converting phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com