Exposed gear grease and preparation method thereof

A technology of gear grease and anti-wear agent, applied in the field of grease, can solve the problem of complex composition, and achieve the effects of strong adhesion, strong extreme pressure and anti-wear, and excellent lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

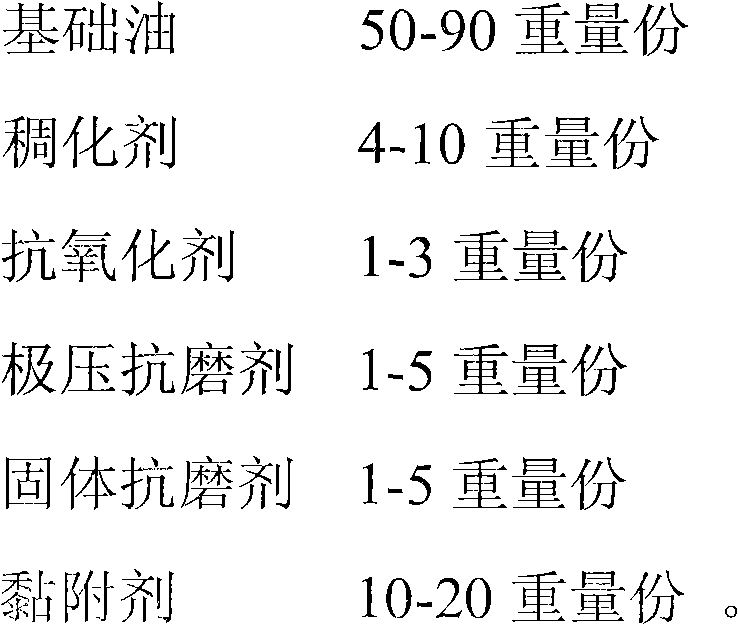

[0025] formula:

[0026] Among them, the base oil has a kinematic viscosity of 680mm at 40°C 2 / s synthetic oil, the thickener is sodium soap; the antioxidant is a mixture of alkyl diphenylamine and 4,4-methylene bis(2,6 di-tert-butylphenol), and the extreme pressure antiwear agent is sulfur phosphorus Anti-wear agent, the solid anti-wear agent is molybdenum disulfide, the particle size of the molybdenum disulfide is 10 μm, and the adhesive is asphalt.

[0027] Preparation:

[0028] (1) Add the formulated amount of base oil into the reaction vessel, heat to 85°C, add the formulated amount of thickener under stirring, and stir at constant temperature for 1.5 hours;

[0029] (2) Cool the mixture obtained in step (1) to 45°C at a constant speed of 1.5°C / min, and then add the formulated amount of antioxidant, extreme pressure antiwear agent, solid antiwear agent and adhesive at a stirring speed of 1100 rpm , continue to stir at constant temperature for 1.5 hours, and then obt...

Embodiment 2

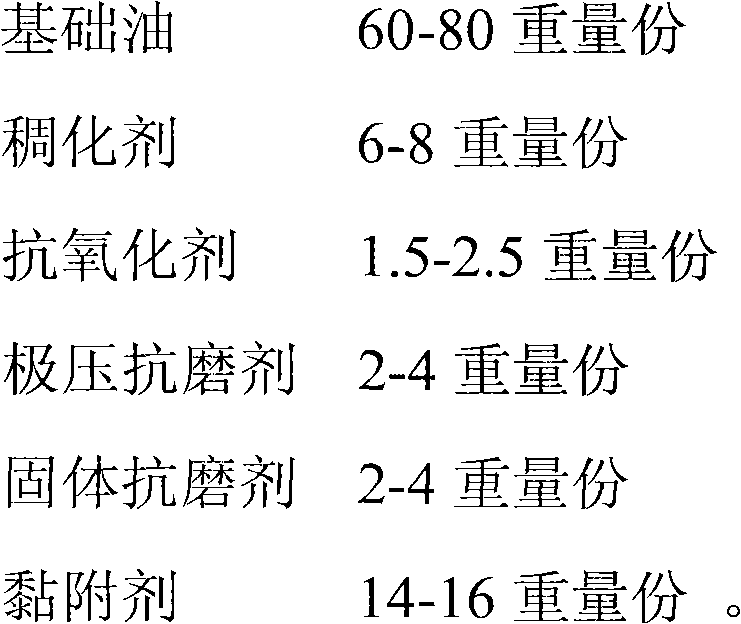

[0031] formula:

[0032]

[0033] Among them, the base oil has a kinematic viscosity of 680mm at 40°C 2 / s synthetic oil, the thickener is a mixture of 12-OH lithium stearate and lithium complex soap; the antioxidant is 4,4-methylene bis(2,6 di-tert-butylphenol), extreme pressure and anti-wear The antiwear agent is sulfur antiwear agent, the solid antiwear agent is molybdenum disulfide, the particle size of the molybdenum disulfide is 1m, and the adhesive is asphalt.

[0034] Preparation:

[0035] (1) Add the formulated amount of base oil into the reaction vessel, heat to 85°C, add the formulated amount of thickener under stirring, and stir at constant temperature for 1.5 hours;

[0036] (2) Cool the mixture obtained in step (1) to 42°C at a constant speed of 1.8°C / min, and then add the formulated amount of antioxidant, extreme pressure antiwear agent, solid antiwear agent and adhesive at a stirring speed of 1100 rpm , continue to stir at constant temperature for 1.9 h...

Embodiment 3

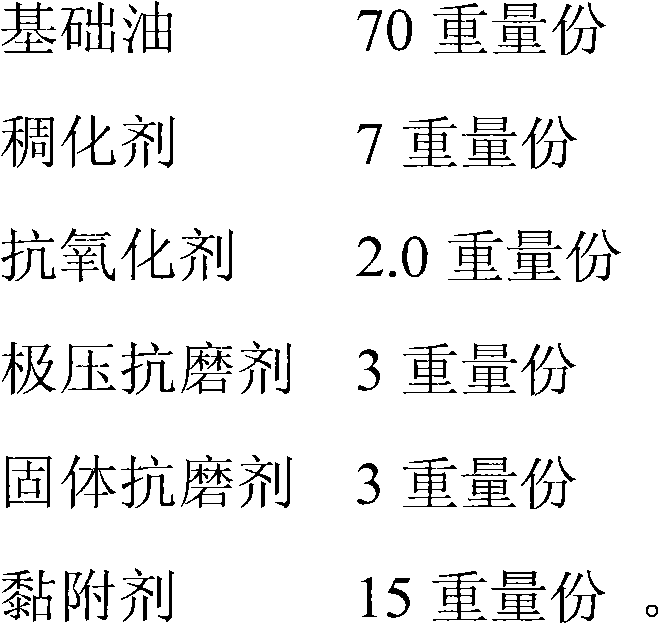

[0038] formula:

[0039] Among them, the base oil has a kinematic viscosity of 680mm at 40°C 2 / s synthetic oil, thickener is complex calcium soap; antioxidant is 4,4-methylene bis(2,6 di-tert-butylphenol), extreme pressure antiwear agent is sulfur phosphorus antiwear agent, solid The anti-wear agent is molybdenum disulfide, the grain size of the molybdenum disulfide is 10 μm, and the adhesive is asphalt.

[0040] Preparation:

[0041] (1) Add the formulated amount of base oil into the reaction vessel, heat to 85°C, add the formulated amount of thickener under stirring, and stir at constant temperature for 1.5 hours;

[0042] (2) Cool the mixture obtained in step (1) to 45°C at a constant speed of 1.5°C / min, and then add the formulated amount of antioxidant, extreme pressure antiwear agent, solid antiwear agent and adhesive at a stirring speed of 1200 rpm , continue to stir at constant temperature for 1.9 hours, and then obtain the finished product after filtration, degas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com