Comprehensive utilization method of lignocellulose biomass

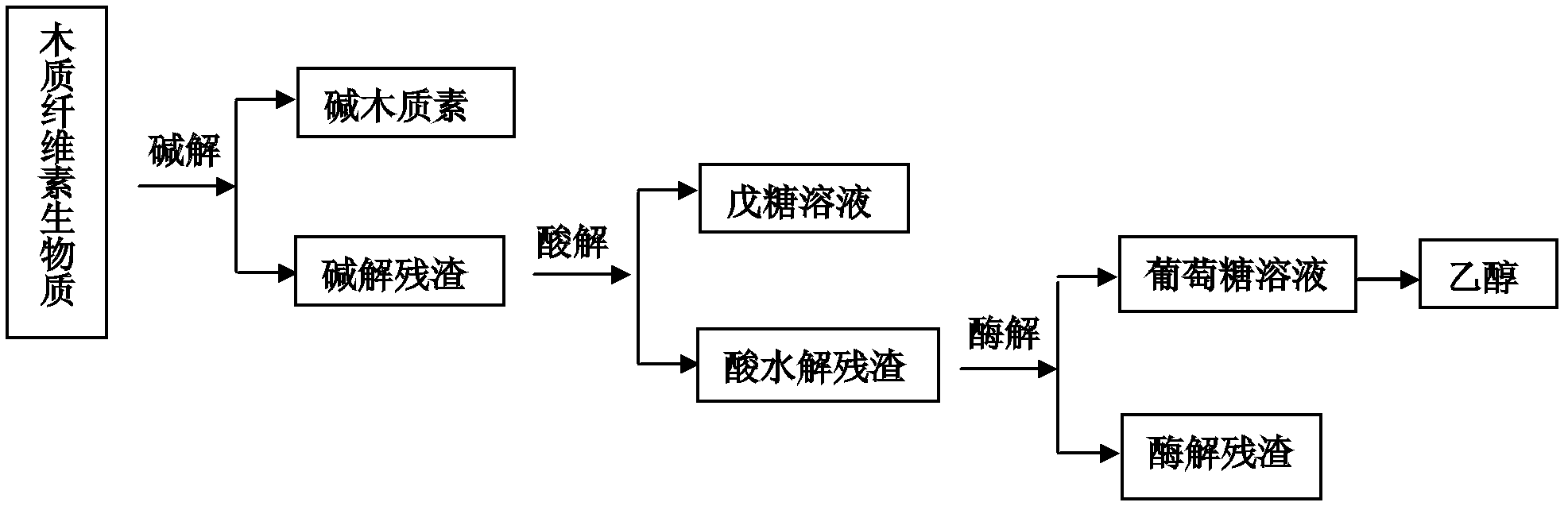

A lignocellulose and biomass technology, applied in the field of comprehensive utilization of cellulose, hemicellulose and lignin in lignocellulosic biomass, can solve the problems of low enzymatic extraction rate of cellulose, and achieve the elimination of space barriers and ease of use. The effect of long-term contact and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Alkali solution to extract alkali lignin

[0050] 10.6kg of crushed corn cobs (mass composition: moisture 6.12%, cellulose 35.19%, hemicellulose 32.1%, lignin 23.7%, other 2.95%, the same below) were broken, washed with water to remove dust, and then hydrogenated Alkaline hydrolysis with sodium oxide solution, wherein the liquid-solid volume ratio is 5:1, the concentration of sodium hydroxide solution is 6%, the temperature is raised to 70°C, and after 2 hours of cooking and alkaline hydrolysis, the alkali hydrolysis residue and alkali lignin solution are separated , with 10kg of water to clean the alkali lignin residue, the cleaning solution is combined with the alkali lignin solution; finally obtain the alkali lignin solution of 20.38kg alkali lignin residue (about 65% moisture content) and 49.61kg; in the alkali lignin solution The content of alkali lignin is 3.16%, and the extraction rate of alkali lignin is 62%.

[0051] The formula of alkali lignin extraction...

Embodiment 2

[0063] (1) Alkali solution to extract alkali lignin

[0064] 10.6 kg of pulverized corn cobs were broken, washed with water to remove dust, and then carried out alkaline hydrolysis with sodium hydroxide solution, wherein the liquid-solid volume ratio was 20:1, the concentration of sodium hydroxide solution was 5%, and the temperature was raised to 100 ° C. After 1 hour of cooking alkaline hydrolysis, the alkali hydrolysis residue and alkali lignin solution are separated, and the alkali hydrolysis residue is cleaned with 10 kg of water, and the cleaning solution is merged with the alkali lignin solution; finally, 19.29 kg alkali hydrolysis residue (moisture content) is obtained 65%) and 200.67kg of alkali lignin solution; the content of alkali lignin in the alkali lignin solution is 0.79%, and the extraction rate of alkali lignin is 63%.

[0065] (2) acid hydrolysis

[0066] Get all the alkali hydrolysis residues that present embodiment (1) alkali hydrolysis treatment obtains,...

Embodiment 3

[0070] (1) Alkali solution to extract alkali lignin

[0071] 10.6 kg of pulverized corn cobs were broken, washed with water to remove dust, and then carried out alkaline hydrolysis with sodium hydroxide solution, wherein the liquid-solid volume ratio was 10:1, the concentration of sodium hydroxide solution was 8%, and the temperature was raised to 40 ° C. After 6 hours of cooking alkaline hydrolysis, the alkali hydrolysis residue and alkali lignin solution are separated, and the alkali hydrolysis residue is cleaned with 10 kg of water, and the cleaning solution is merged with the alkali lignin solution; finally, 21.47 kg alkali hydrolysis residue (moisture content) is obtained About 65%) and 93.85kg of alkali lignin solution; the content of alkali lignin in the alkali lignin solution is 1.53%, and the extraction rate of alkali lignin is 57%.

[0072] (2) acid hydrolysis

[0073] Get all the alkali hydrolysis residues that present embodiment (1) alkali hydrolysis treatment obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com