Destressing method applied to satellite aluminum alloy riveting bearing barrel

A technology for riveting bearing cylinders and aluminum alloys, applied in the field of stress relief, can solve problems such as deformation of satellite aluminum alloy riveting bearing cylinders, and achieve the effects of stable product structure and dimensions, improving product quality, and improving resistance to dynamic loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following The described embodiment:

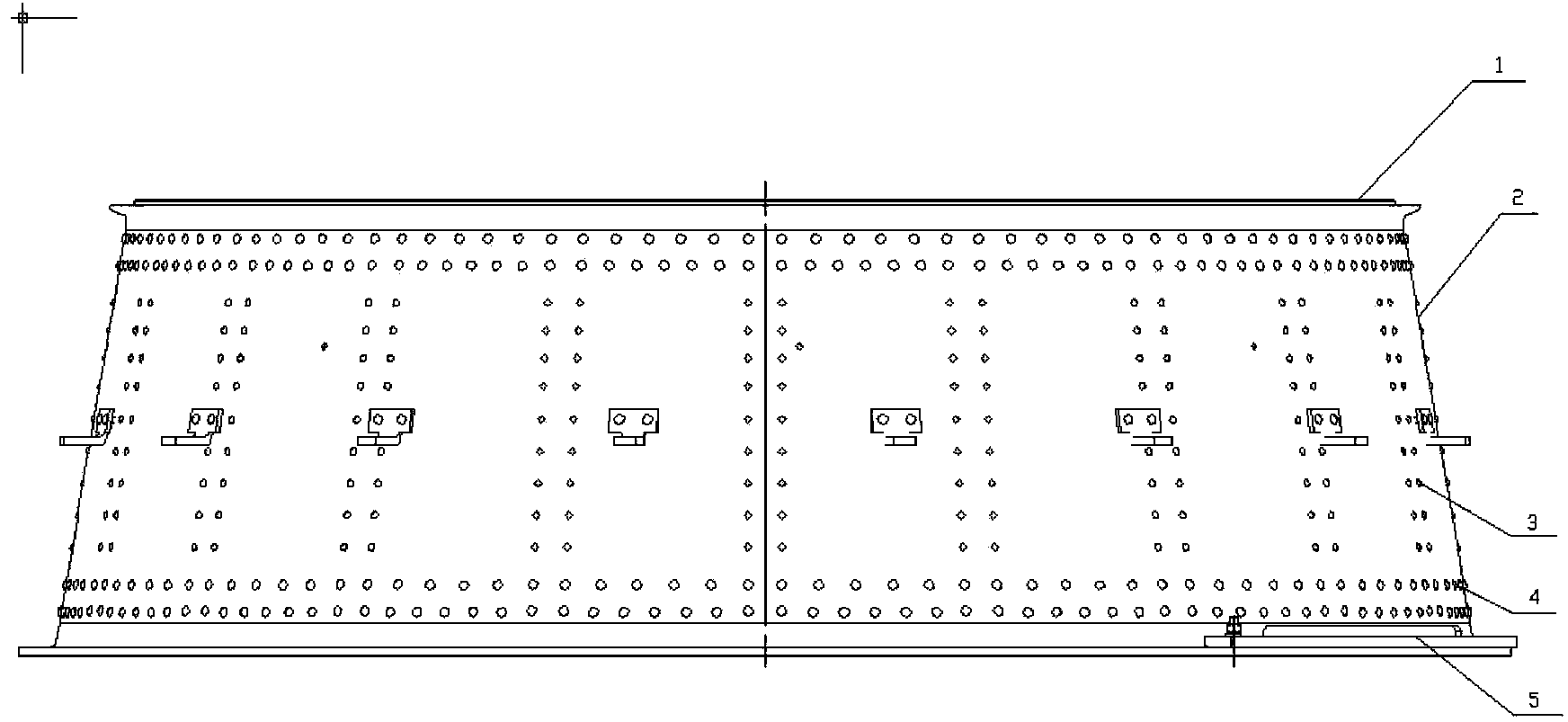

[0031] Such as figure 1 Shown is the aluminum alloy riveted bearing tube of a certain type of satellite, which mainly includes the upper and lower end frames made of 2A14T6, the skin and stringers of 2A12T4, and various rivets made of 2A01 are used for riveting.

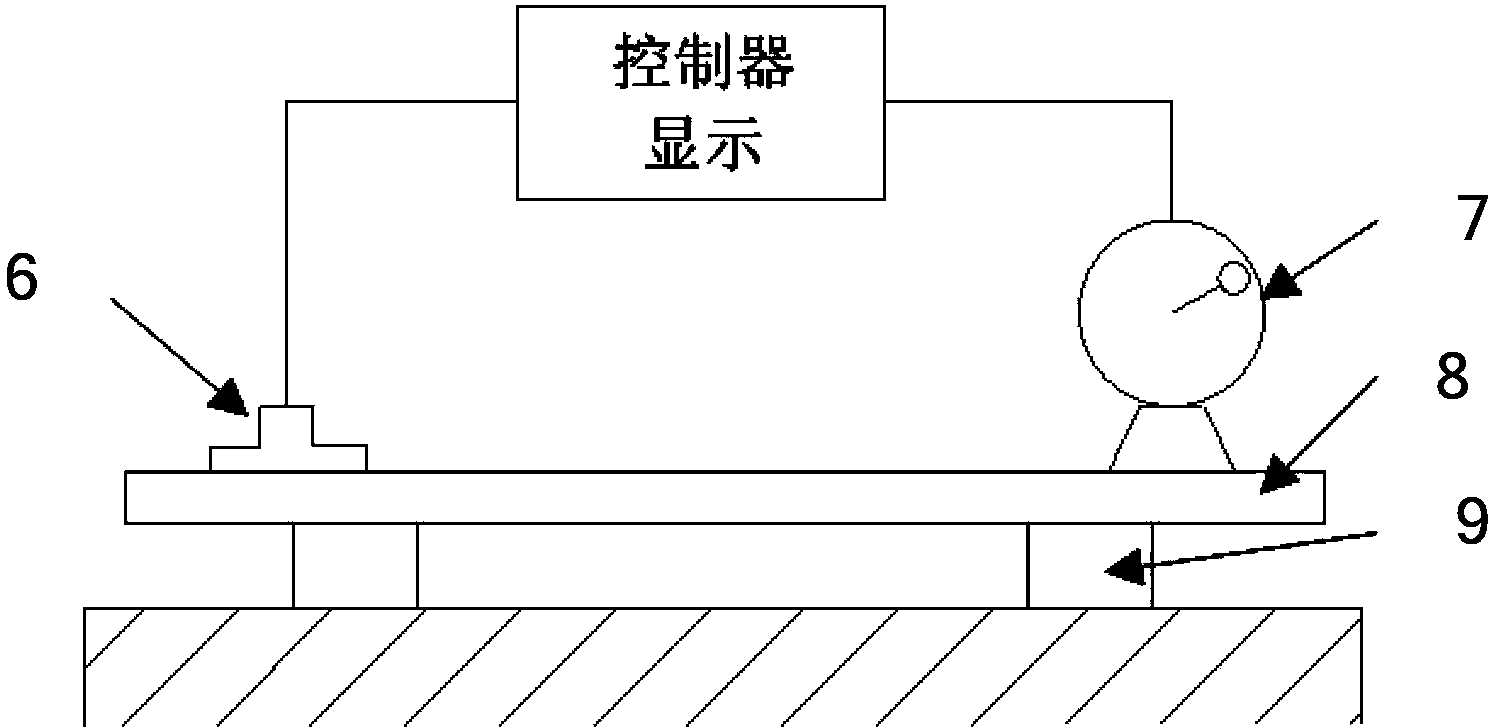

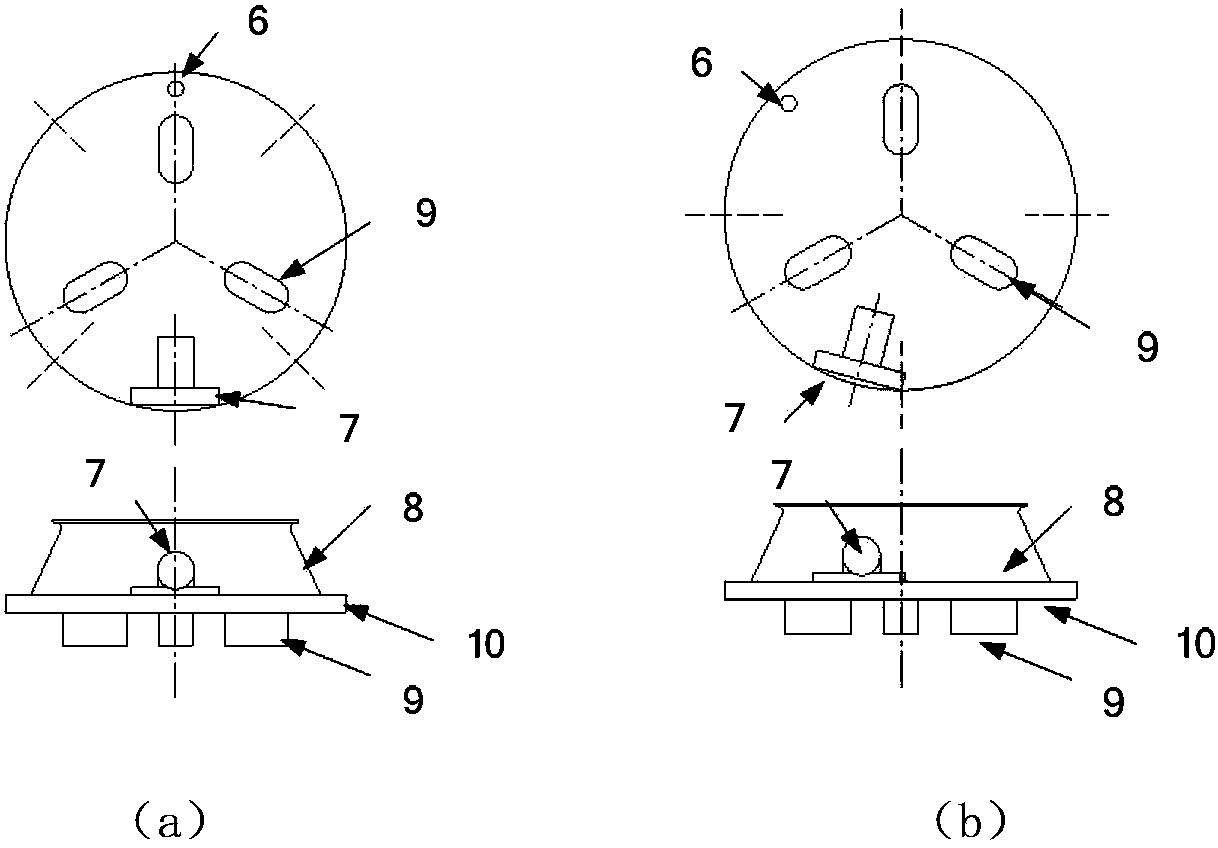

[0032] Such as figure 2 Shown is the vibration aging equipment, which is mainly composed of processor, workpiece, tooling, vibration excitation motor, elastic rubber pad, vibration picker and so on. The test equipment is placed on the ground with a good level. The system consists of a data acquisition mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com