Manufacturing technique for machine washable slubbing pure wool fabric

A manufacturing process and fabric technology, applied in the field of woolen machine washable pure wool fabric manufacturing process, can solve the problems of insufficient softness, unclear workers, and reduced felting resistance of fabrics, so as to achieve long-lasting anti-felting effect and anti-felting Excellent shrinkage effect and high fabric fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

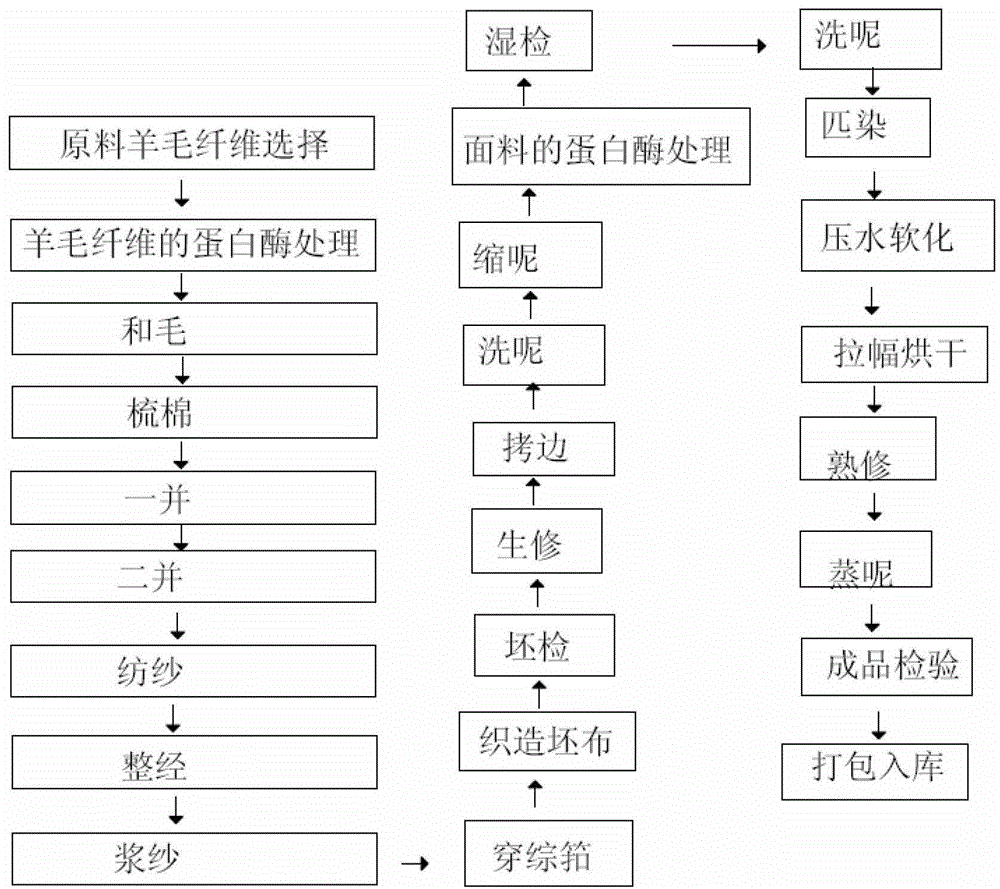

[0020] The manufacturing process of the slubbed machine-washable pure wool fabric of the present invention, such as figure 1 As shown, the process flow is: raw wool fiber selection→protease treatment of raw wool fiber→wool blending→carding→one combining→two combining→spinning→warping→sizing→threading heald reed→weaving gray cloth→white inspection →Repair→Overlap→Washing→Shrinking→Protease treatment of fabrics→Wet inspection→Washing→Piece dyeing→Pressed water softening→Stenter drying→Familiar repairing→Steaming→Finished product inspection→Packing and storage.

[0021] The above-mentioned technological process includes a protease treatment process, and the protease treatment process here includes the protease treatment process of the raw wool fiber and the protease treatment process of the fabric. Among them, the protease treatment process of the raw wool fiber is to remove 30-50% of the scales on the surface of the raw wool fiber through protease treatment before the kneading p...

Embodiment 2

[0024] On the basis of Example 1, the preferred embodiment of the present invention can be: in the described protease treatment process, the consumption of CTA-B protease is 0.3% of raw material wool fiber or fabric quality, bath ratio is 1:20, pH value It is 7.5~7.8, and the temperature is 50°C.

[0025] In addition, the protease treatment time of the raw wool fiber is 8-15 minutes, and the protease treatment time of the fabric is 15-22 minutes.

Embodiment 3

[0027] On the basis of Example 1, the preferred embodiment of the present invention can be: in the described protease treatment process, the consumption of CTA-B protease is 0.5% of raw material wool fiber or fabric quality, and bath ratio is 1:45, pH The value is 8~9, and the temperature is 55°C.

[0028] In addition, the protease treatment time of the raw wool fiber is 36-60 minutes, and the protease treatment time of the fabric is 60-84 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com