Horizontal type two-channel pulverized coal fired boiler

A pulverized coal boiler, dual-channel technology, used in steam boilers, water-tube steam boilers, boiler smoke pipes/fire pipes, etc., can solve problems such as short circuit of flue gas, and achieve the effects of short production cycle, easy operation and less air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

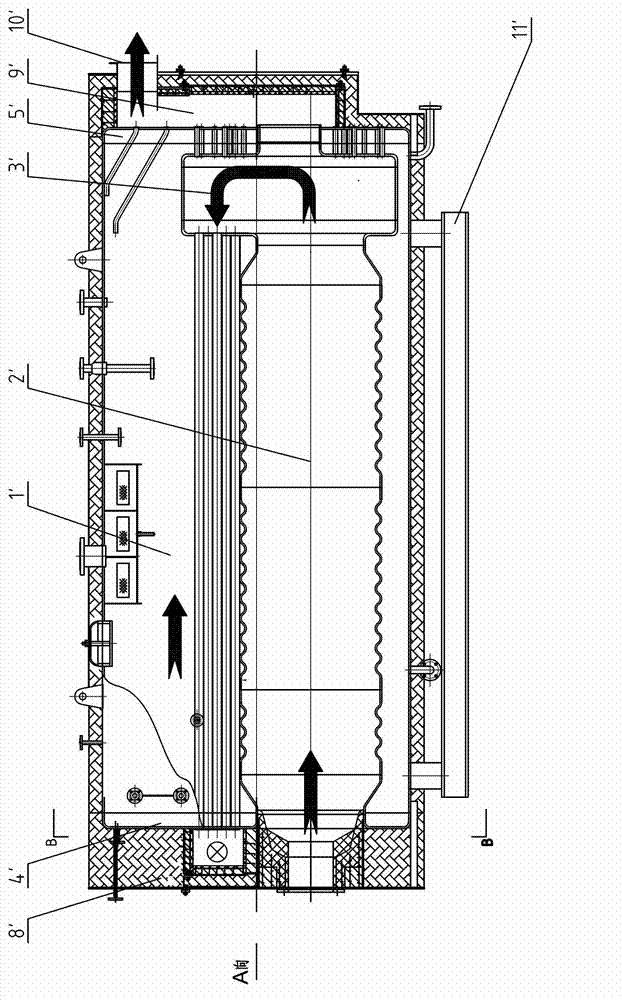

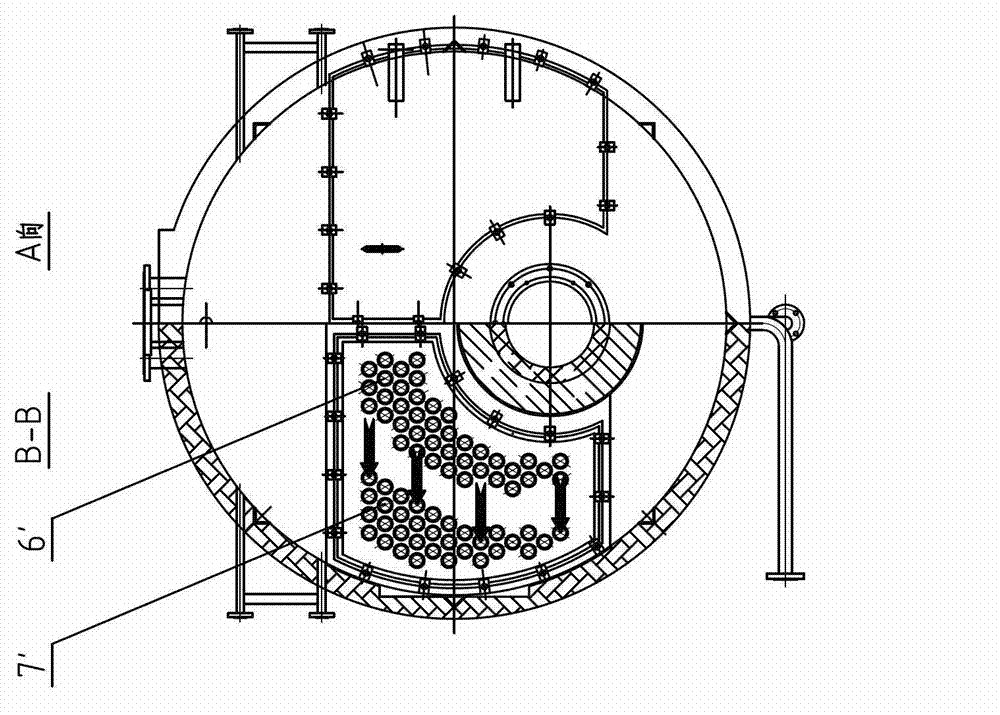

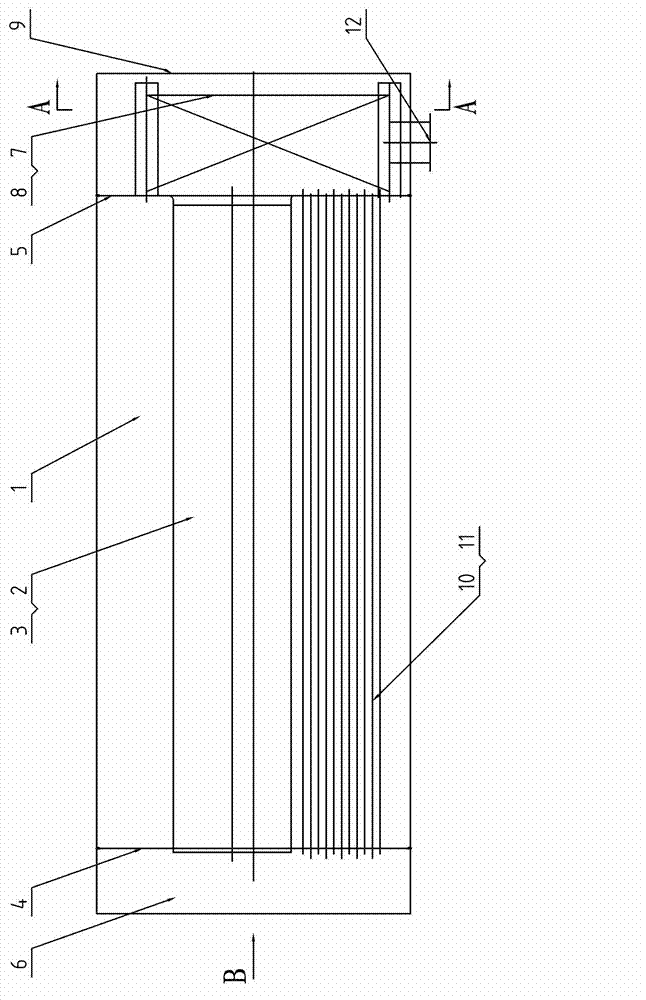

[0036] Refer to attached image 3 , Figure 4 and Figure 5 , a horizontal double-channel pulverized coal boiler of the present invention, comprising a pot shell cylinder 1, a left externally hanging cylinder 15 and a right externally hanging cylinder 16, said pot shell cylinder 1 is provided with a left furnace 2, a right Furnace gall 3, front tube plate 4, rear tube plate 5, front smoke box 6, left back combustion chamber 7, right back combustion chamber 8, outboard plate 9, left second return smoke pipe 10 and right second return smoke pipe 11, all The left furnace 2, the right furnace 3, the left two-pass smoke pipe 10 and the right two-pass smoke pipe 11 are arranged in the boiler body 1 through the front tube plate 4 and the rear tube plate 5; The front smoke box 6 and the outer cladding plate 9 are arranged on the front and rear ends of the pot shell body 1 respectively, and the bottom of the outer cladding plate 9 is provided with an ash drop port 12; the left two re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com