Straight-through type C-shaped bourdon tube high-pressure sulfur-resisting pressure gauge and manufacturing method thereof

A technology of spring tube and pressure gauge, which is applied in the direction of fluid pressure measurement of elastic deformation gauge, measuring fluid pressure, instruments, etc., to achieve the effect of weakening corrosion, easy maintenance, and simple and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

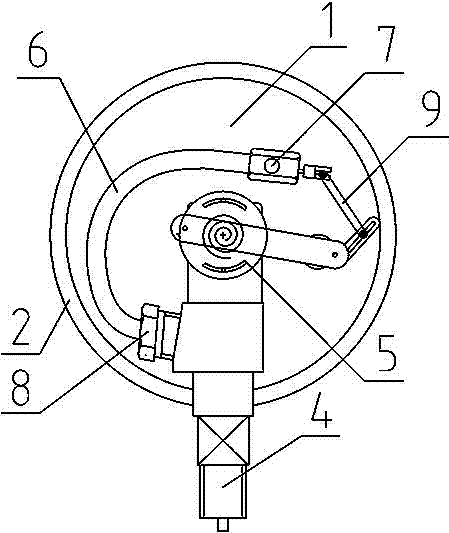

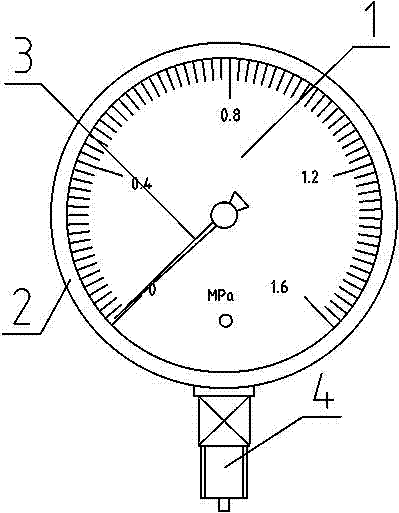

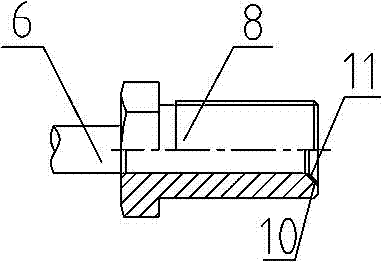

[0031] Such as figure 1 As shown, a straight-through C-shaped spring tube high-pressure sulfur-resistant pressure gauge, which includes a dial 1, a transparent cover 2 set outside the dial 1, a pressure measurement mechanism 5 installed on one side of the dial 1 and installed on the other side of the dial 1 The pointer 3 on the side is connected to the pressure measuring mechanism 5, and it also includes a joint 4, a C-shaped spring tube 6, an upper joint 7, a lower joint 8 and a connecting rod 9. The joint 4 is arranged at the bottom of the dial 1, and the joint One end of 4 is a free end, and the other end of the joint 4 is connected to one end of the C-shaped spring tube 6 through the lower connector 8, which is sleeved on the C-shaped spring tube 6, and the lower connector 8 is close to one end of the joint 4. A gasket groove 10 with a tapered surface is provided on the end surface of the side, and a gasket 11 closely matched with it is placed in the gasket groove 10. The ...

Embodiment 2

[0047] Its structure is with embodiment 1.

[0048] A method for making a straight-through C-shaped spring tube high-pressure sulfur-resistant pressure gauge, which includes two steps of manufacturing a C-shaped spring tube 6 and pressure gauge assembly, wherein the manufacturing of the C-shaped spring tube 6 includes the following sub-steps :

[0049] S11: Prepare blanks: select Φ16.5mm nickel-based alloy rods, cut into lengths of 178mm;

[0050] S12: Processing shape: the outer diameter of the nickel-based alloy bar is turned to Φ16mm, and the length is 175mm;

[0051] S13: Processing the inner hole: Drill the inner hole of the nickel-based alloy rod to ensure that its inner diameter is Φ6.6mm, and then ream and bore the hole to make the inner hole diameter of the nickel-based alloy rod Φ7.2mm, and the smoothness reaches ▽5;

[0052] S14: Threading: use a lathe to process threads on both ends of the nickel-based alloy bar, the size is M14×1.25-14, one end is left-handed t...

Embodiment 3

[0061] Its structure is with embodiment 1.

[0062] A method for making a straight-through C-shaped spring tube high-pressure sulfur-resistant pressure gauge, which includes two steps of manufacturing a C-shaped spring tube 6 and pressure gauge assembly, wherein the manufacturing of the C-shaped spring tube 6 includes the following sub-steps :

[0063] S11: Prepare blanks: select Φ17mm nickel-based alloy rods, cut into lengths of 180mm;

[0064] S12: Processing shape: the outer diameter of the nickel-based alloy bar is turned to Φ16mm, and the length is 175mm;

[0065] S13: Machining the inner hole: Drill the inner hole of the nickel-based alloy bar to ensure that its inner diameter is Φ6.7mm, and then ream and bore the hole so that the inner hole diameter of the nickel-based alloy bar is Φ7.2mm, and the smoothness reaches ▽5;

[0066] S14: Threading: use a lathe to process threads on both ends of the nickel-based alloy bar, the size is M14×1.25-14, one end is left-handed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com