Power inductor and manufacturing method thereof

A technology of a power inductor and a manufacturing method, which is applied to the field of power inductors and their manufacturing, can solve the problems of occupying powder space, high cost of electrodes, and reduction of powder materials, so as to reduce labor costs, high temperature characteristics, and cost control improvement and reduction. The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

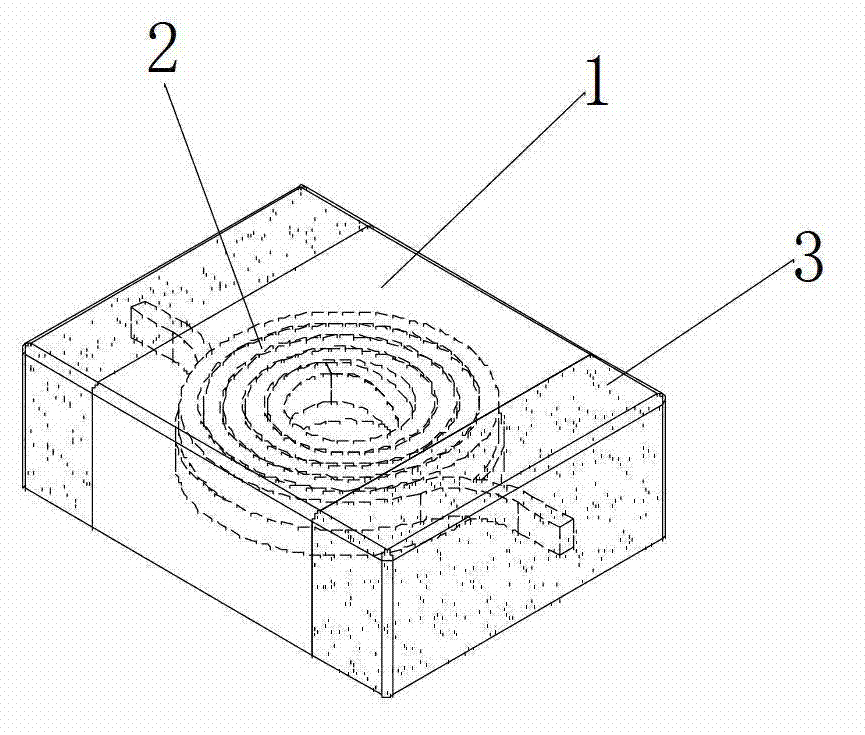

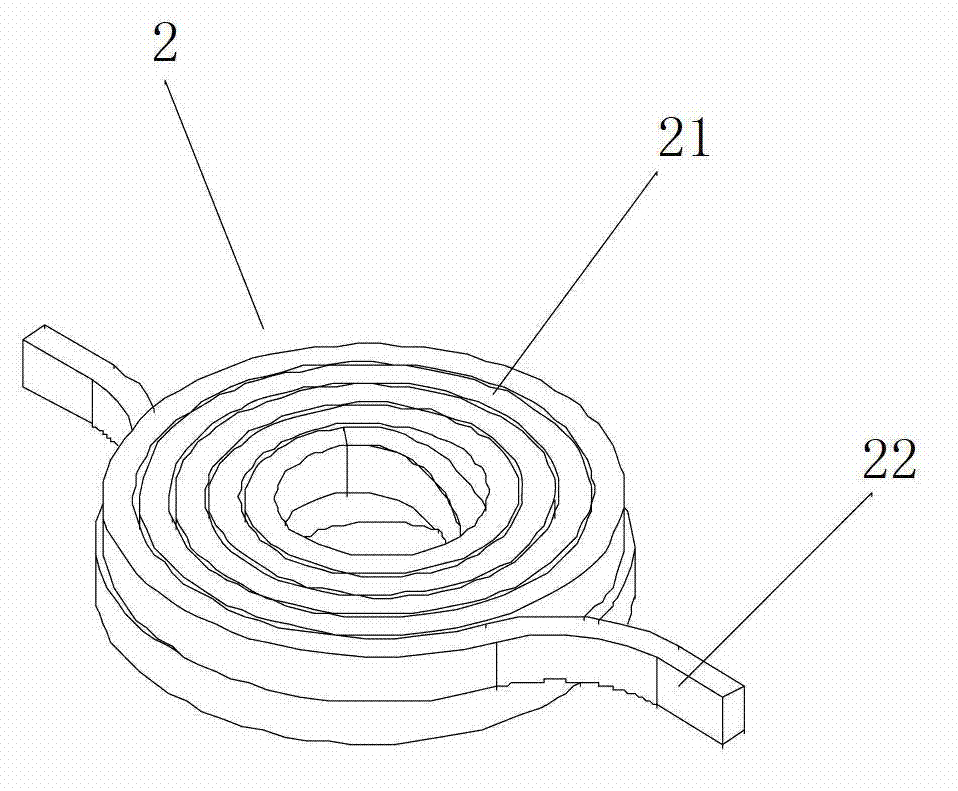

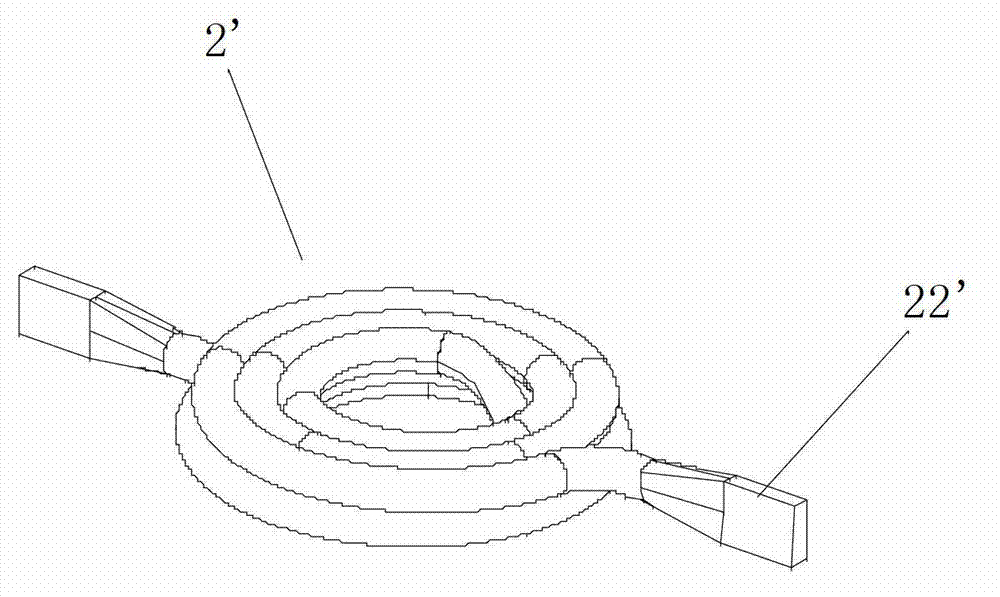

[0031] like figure 1 and figure 2 As shown, the power inductor of the present invention includes an inner core 2 and a die-cast body 1 tightly covering the inner core 2 . The inner core 2 is a coil structure wound by an enameled wire, and includes a main body 21 and an extension 22 extending from the main body 21 . The extension 22 is flat. The die-casting body 1 is formed by integrally die-casting the inner core 2 with magnetic metal powder. The die-casting body 1 seals the inner core 2 therein with high density, and the extension part 22 exposes the opposite end surface of the die-casting body 1 .

[0032] The enameled wire adopts high-strength hot-melt (high temperature resistant) enameled wire, which can be flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com