Manufacturing method of MLCOB (Multi Lens Chips On Board) light source module

A manufacturing method and technology of light source modules, which are applied in electrical components, electric solid state devices, circuits, etc., can solve problems such as poor welding, affect product performance, and easy to appear defective, and achieve low cost, high precision, and simple molding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings of the description.

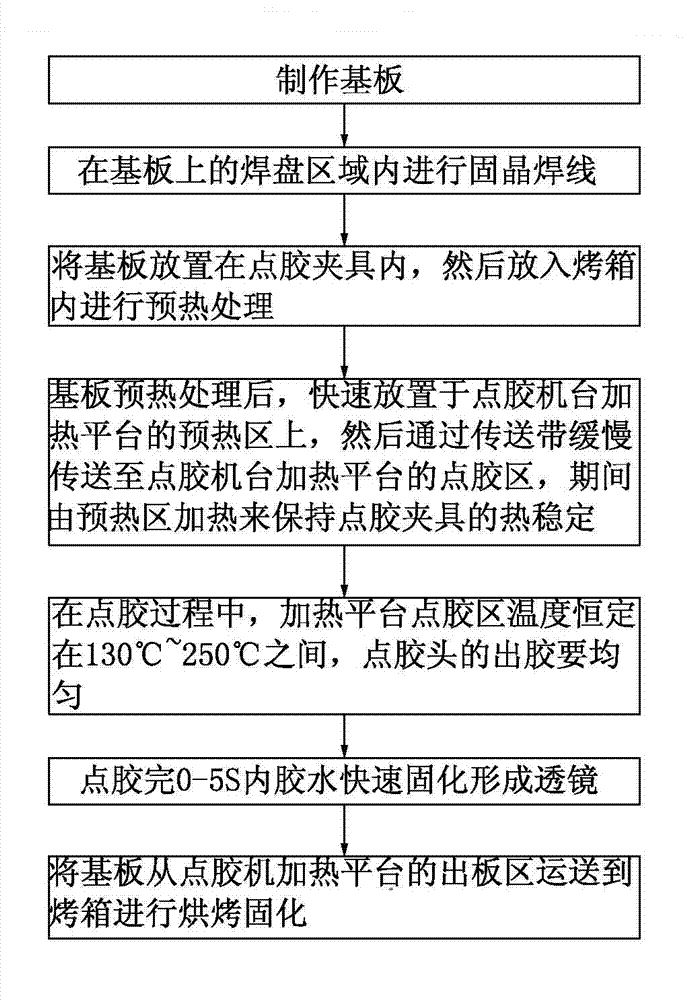

[0034] Such as figure 1 , 2 Shown, a kind of manufacturing method of MLCOB light source module comprises the following steps:

[0035] (1) Manufacturing the substrate; the substrate includes an insulating layer 1, a circuit layer 2, and a solder mask layer 3 arranged in sequence from bottom to top; the manufacturing method is as follows: select a glass fiber board to make the main material of the substrate, and manufacture the circuit layer 2 on the substrate, Print white oil on the circuit layer 2 to form a white oil layer, and finally make pads on the reserved area on the circuit layer 2; the thickness of the white oil layer on the substrate is 0.01~0.1mm, and use high reflectivity ink to coat the surface of the substrate to form a white oil layer , this white oil layer can reflect the light emitted from the side of the light source on the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Lens diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com