Food enzymolysis equipment and its operation method

A technology of enzymatic hydrolysis and equipment, which is applied in the field of food enzymatic hydrolysis equipment, can solve the problems of large investment in equipment, achieve the effects of less investment in equipment, reduce production costs, and avoid mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Please refer to the accompanying drawings to further illustrate the present invention. The present invention can not only peel common fruits by enzymatic peeling, but also peel berries by enzymatic peeling; it can also be applied to citrus foods and other melons and fruits. Take off the coat.

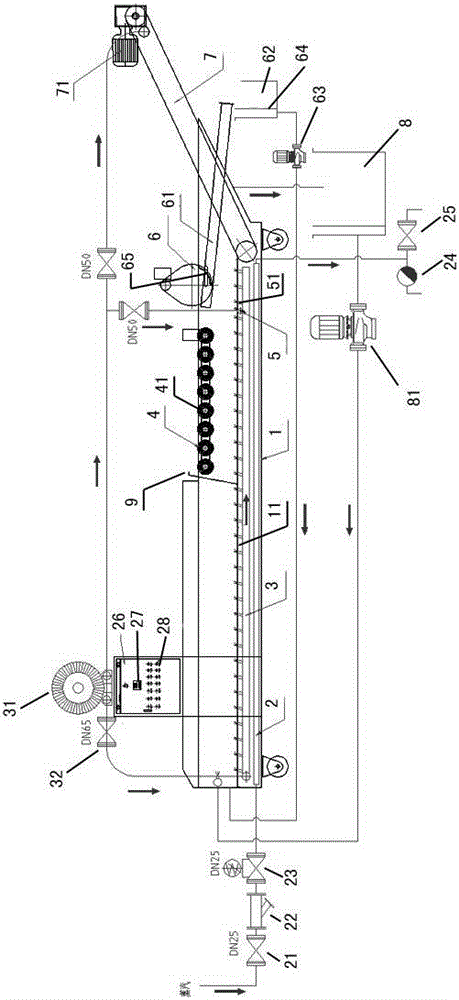

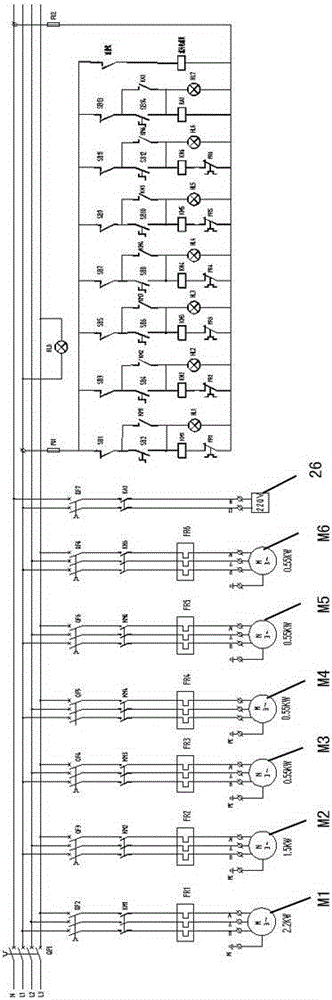

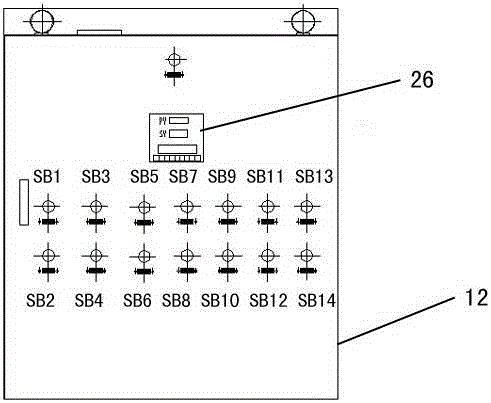

[0066] Such as figure 1 As shown in the schematic diagram of the structure of the present invention, a food enzymatic hydrolysis equipment is used for fruit peeling and / or decapsulation, including a box body 1, and fruit and enzyme liquid are mixed as enzymatic hydrolysis materials and placed in the box body 1, and are controlled electronically. The box 12 controls the enzymatic hydrolysis process. In the box body 1, a steam coil heating device 2, a bubble turning device 3, a partition 11 for placing materials, a brush cleaning device 4, and a float turning device are arranged in sequence from bottom to top 5. Floating object removal device 6, wherein, the floating object turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com