Device and method for processing one glass solution (OGS) touch screens

A technology of touch screen and dust collection device, applied in glass cutting device, metal processing equipment, manufacturing tool, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

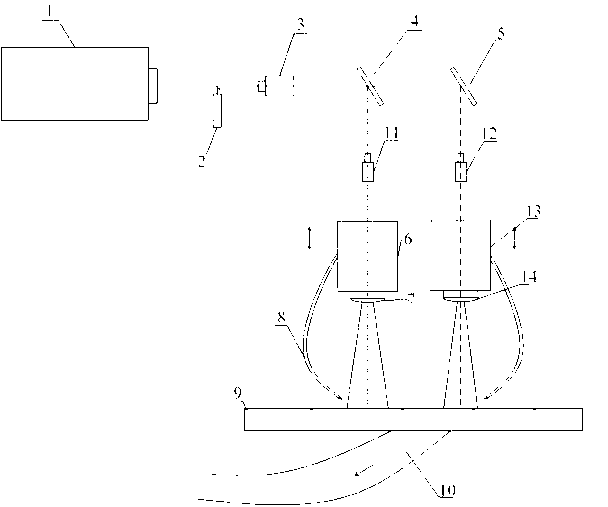

[0017] The invention uses a green high-frequency ultra-short pulse laser to process the special-shaped part of the OGS touch screen, then uses a cutter wheel to cut and split the straight part, and combines CNC for subsequent fine grinding to improve efficiency and yield.

[0018] Such as figure 1 As shown, the device for processing the OGS touch screen includes a green ultrashort pulse laser 1, a 45-degree half-mirror 4, a 45-degree total reflection mirror 5, a first 3D dynamic scanning galvanometer 6 and a second 3D dynamic scanning galvanometer 13. The green ultrashort pulse laser 1 is a laser with a pulse width of 1 ps to 15 ns and a frequency of 1 KHz to 5 MHz. The output end of the green ultrashort pulse laser 1 is arranged with an optical gate 2, and the output end of the optical gate 2 is provided with Beam expander 3, the output end of beam expander 3 is arranged with 45 degree half mirror 4, the output end of 45 degree half mirror 4 is provided with first coaxial CCD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com