Ceramic high carbon polymer matrix composite and preparation method thereof

A composite material and polymer technology, which are applied in the field of ceramizable high-carbon polymer-based composite materials and their preparation, to improve the performance of high temperature and high-speed airflow erosion resistance, improve ablation and heat insulation performance, and have a low ceramization temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] The ceramizable high-carbon polymer-based composite material provided in this embodiment is composed of thermosetting high-carbon resin, eutectic mixture, clay-like layered mineral powder, and molding aids, in parts by weight: 15 parts of thermosetting high-carbon resin, 10 parts of eutectic mixture, 20 parts of clay-like layered structure mineral powder, and 0.1 part of molding aid.

Embodiment 3

[0044] The ceramizable high-carbon polymer-based composite material provided in this embodiment is composed of thermosetting high-carbon resin, eutectic mixture, clay-like layered mineral powder, and molding aids, in parts by weight: 32.5 parts of thermosetting high-carbon resin, 7.5 parts of eutectic mixture, 35 parts of clay-like layered structure mineral powder, and 0.8 part of molding aid.

[0045] In the above product examples, the thermosetting high carbon resin is a mixture of one or more of bismaleimide resin, polyphenylene resin, high temperature resistant phenolic resin and polybenzimidazole resin.

[0046] In the above product examples, the clay-like layered structure mineral powder can undergo crystal transformation at temperatures above 1100° C. to form a ceramic phase with a higher melting point and higher hardness.

[0047] In the above product examples, the clay layered mineral powder is a mixture of one or more of talc, mica powder, kaolinite, montmorillonite ...

Embodiment 1

[0053] (1) Weigh 40 parts of mica powder, 50 parts of boron phenolic resin, 10 parts of eutectic mixture, and 0.1 part of zinc stearate and add them to a high-speed mixer for mixing;

[0054] (2) Heat the mixture to a hot-melt state, vacuumize and defoam, then place it on a hot press at 160 ° C to 200 ° C, and mold it under a pressure ≥ 5Mpa for 3 to 4 hours, and then demould it for later use;

[0055] The prepared sample was subjected to a dynamic ablation experiment with a Bunsen burner, the flame was 10mm away from the sample, and the ablation was performed for 15 minutes. The thermal weight loss rate of the sample after ablation is less than 10%, and the dimensional change of the sample after the test is less than 5%. The ablation surface of the material remains intact, and there is no delamination, obvious peeling, peeling and other problems.

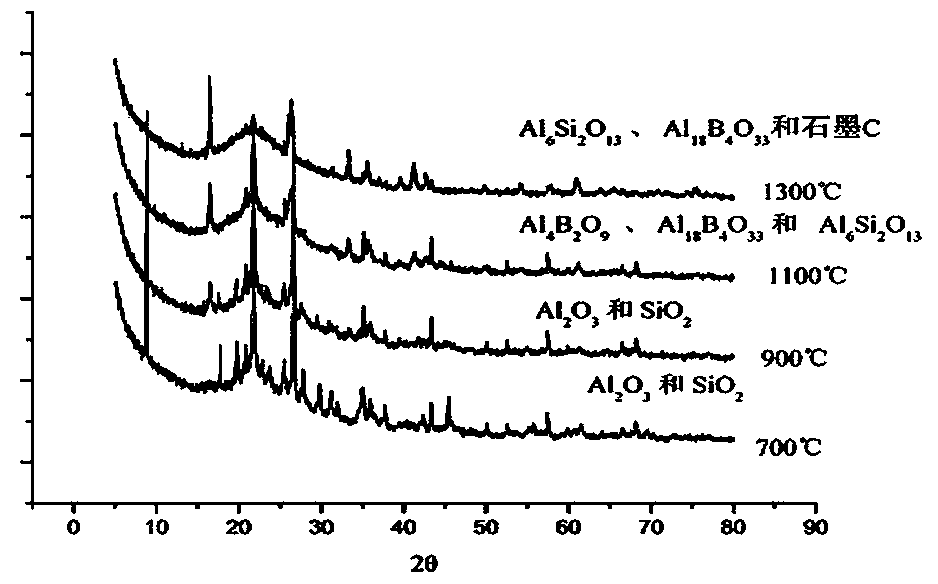

[0056] figure 1 are the XRD patterns of the ablation samples at ablation temperatures of 700°C, 900°C, 1100°C, and 1300°C, respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com