Method for preparing alpha-lipoic acid

A lipoic acid and sodium lipoic acid technology, applied in the direction of organic chemistry, can solve the problems of difficult to increase yield, cumbersome synthesis steps, and harsh conditions, and achieve the effects of improving purity, reducing the formation of impurities, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 80 g of purified water into a 500 mL beaker, add 21.8 g of sodium sulfide under stirring, dissolve at 35° C., and prepare a sodium sulfide solution.

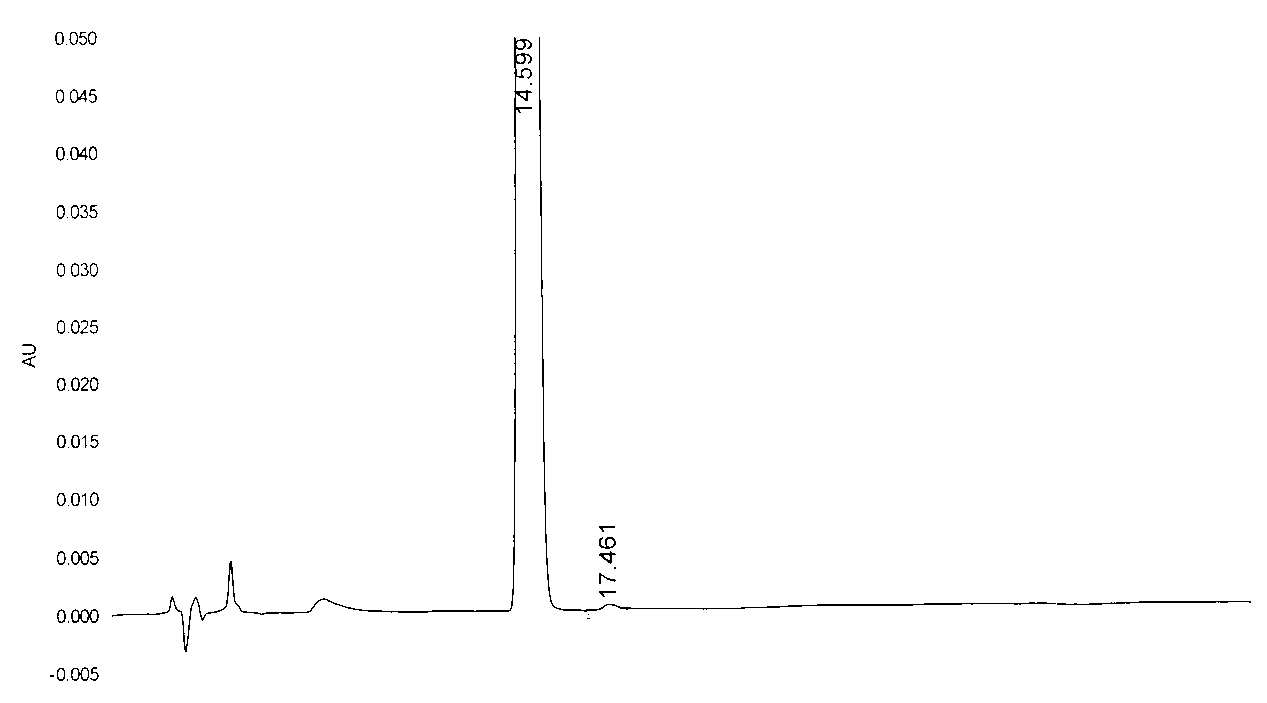

[0046] Into a 500 mL round bottom flask, 50 g of ethyl 6.8-dichlorooctanoate, 150 g of purified water, 8 g of sulfur, and 3.5 g of tetrabutylammonium bromide were added. Heat to 82°C under stirring, add sodium sulfide solution dropwise, and finish dropping in 1 hour, and the dropping temperature is kept at 70°C. After the dropwise addition, the reaction was continued for 5 hours, the temperature was lowered to 65° C., and the mixture was left to stand for about 60 minutes, and the layers were separated to obtain 48.3 g of ethyl lipoic acid. Then put ethyl lipoic acid, 1600g of drinking water, 24.2g of sodium hydroxide and 1.93g of tetrabutylammonium bromide into the hydrolysis kettle into a 3000mL reaction kettle, stir, heat to 70°C, keep it warm for 13 hours, and pump it out while it is hot. Filter it into a 5L reac...

Embodiment 2

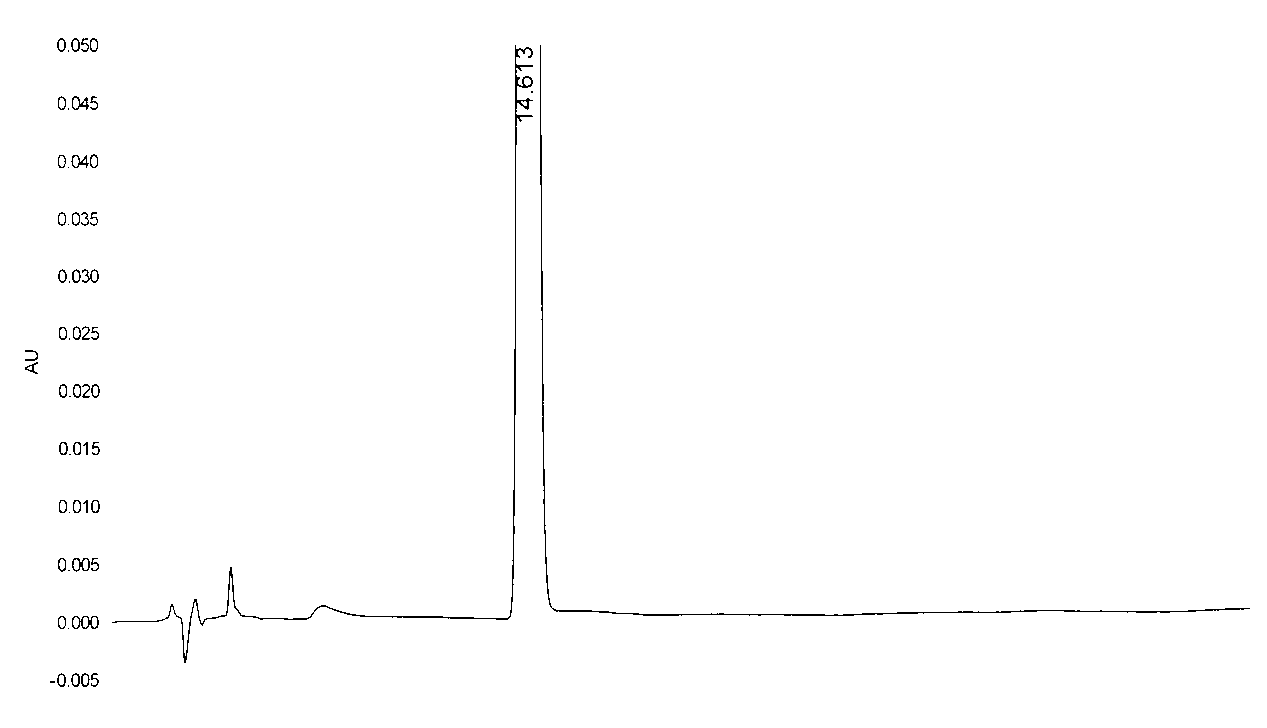

[0050] Add 120g of purified water into a 500mL beaker, add 31.2g of sodium sulfide under stirring, dissolve at 40°C, and prepare a sodium sulfide solution.

[0051] In a 500 mL round bottom flask, 50 g of ethyl 6.8-dichlorooctanoate, 150 g of drinking water, 15 g of sulfur, and 3.5 g of tetrabutylammonium bromide were added. Heat to 84°C under stirring, add sodium sulfide solution dropwise, and finish dropping in 1.5 hours, and keep the dropping temperature at 86°C. After the dropwise addition, the reaction was continued for 5 hours, the temperature was lowered to 65° C., and the mixture was left to stand for about 60 minutes, and the layers were separated to obtain 48.1 g of ethyl lipoic acid. Then put ethyl lipoic acid, 1600g of drinking water, 48.1g of sodium hydroxide and 1.92g of tetrabutylammonium bromide into the hydrolysis kettle into a 3000mL reaction kettle, stir, heat to 50°C, keep it warm for 13 hours, and pump it out while it is hot. Filter into a 5L reaction ket...

Embodiment 3

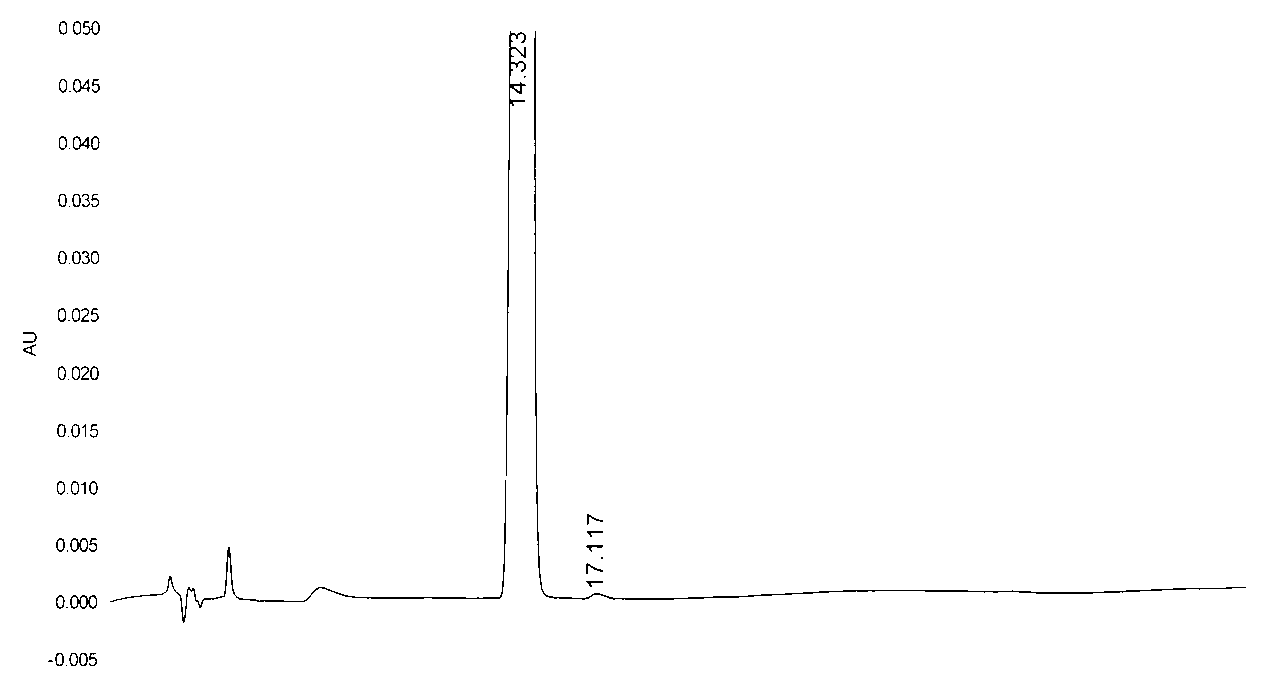

[0055] Add 100 g of purified water into a 500 mL beaker, add 25 g of sodium sulfide under stirring, dissolve at 37°C, and prepare a sodium sulfide solution.

[0056] In a 500 mL round bottom flask, add 50 g of ethyl 6.8-dichlorooctanoate, 150 g of drinking water, 10 g of sulfur, and 3.5 g of tetrabutylammonium bromide. Heat to 83°C under stirring, add sodium sulfide solution dropwise, and finish dropping in 1.2 hours, the dropping temperature is kept at 84°C. After the dropwise addition, the reaction was continued for 5 hours, the temperature was lowered to 65° C., and the mixture was left to stand for about 60 minutes, and the layers were separated to obtain 47.7 g of ethyl lipoic acid. Then put ethyl lipoic acid, 1600g of drinking water, 54.8g of sodium hydroxide and 1.9g of tetrabutylammonium bromide into the hydrolysis kettle into a 3000mL reaction kettle, start stirring, heat to 80°C, and keep it warm for 13 hours. Suction filter into a 5L reaction kettle, add dropwise 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com