Inorganic mineral filled wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and inorganic mineral materials, which is applied in the field of wood-plastic composite materials, can solve the problems that wood raw materials are not suitable for multiple use, and achieve the effects of good processability, reduced investment, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific examples, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0044] (1) Take some crushed 80-mesh wood chips and put them into a dryer for drying. The drying temperature is 115°C-120°C, and the drying time is 2 hours;

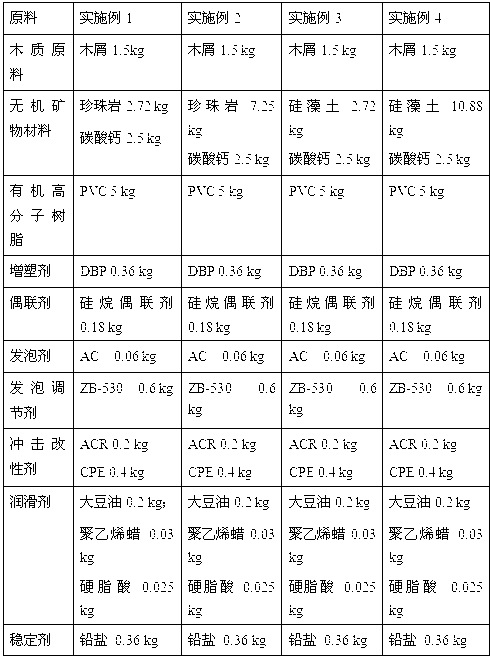

[0045] (2) Accurately weigh the raw materials in Table 1, put them into a high-speed mixer after mixing, and wait for the self-friction heat to reach 106°C, and then naturally drop to room temperature;

[0046] (3) Start the twin-screw extruder, and set four temperature zones between the feed port, the barrel and the outlet die, which are respectively 166°C in the first barrel zone, 169°C in the second barrel zone, and 171°C in the third barrel zone. ℃, machine head 174 ℃, after the standby body rises to the set temperature, put in the mixed raw materials i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com