Device for preparing natural nanometer fibers through continuous ultrasonic method and continuous ultrasonic method

A technology of nanofiber and ultrasonic method, which is applied in fiber treatment, spinning solution preparation, textile and papermaking, etc., can solve the problem of inability to meet the needs of large-scale industrial production of natural nanofibers, uneven energy distribution of natural nanofibers, and non-continuous Chemical processing and other issues, to achieve uniform treatment effect, large ultrasonic radiation area, to meet the effect of large production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

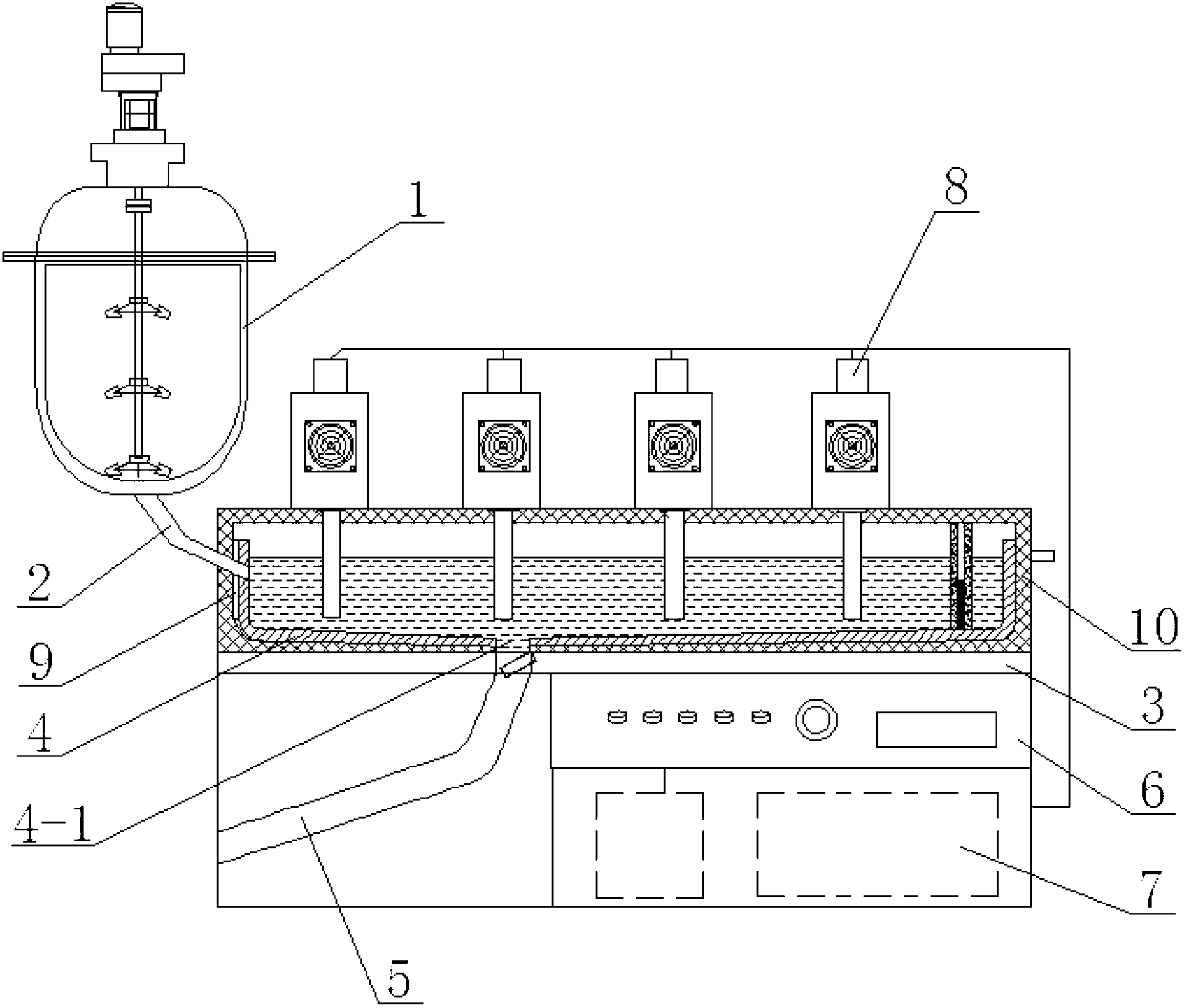

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises ultrasonic device, reactor 1 and feed pipe 2, and described ultrasonic device comprises workbench 3, ultrasonic tank 4, discharge pipe 5, controller 6, ultrasonic generator 7 and several Ultrasonic transducer 8, the ultrasonic tank 4 is embedded in the inside of the workbench 3, the bottom of the ultrasonic tank 4 is provided with a discharge port 4-1, and the input end of the discharge pipe 5 is connected to the discharge port 4-1 , several ultrasonic transducers 8 are evenly distributed along the length direction of the ultrasonic tank 4, and the probe end of each ultrasonic transducer 8 is arranged in the ultrasonic tank 4, and the controller 6 and the ultrasonic generator 7 are arranged in sequence in the ultrasonic tank 4. Below the workbench 3, the controller 6 is used to control the ultrasonic power, ultrasonic gap time, display operating parameters and fault al...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that it also has a temperature controller 9 which is arranged on the outer wall of the ultrasonic tank 4 . The temperature controller 9 plays the role of controlling the temperature in the ultrasonic tank 4 . Thermostat 9 is a commercially available product. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the specific embodiment 1 or 2 is that it also adds a sound insulation wall 10 , and the sound insulation wall 10 is laid along the six sides of the ultrasonic tank 4 . The sound insulation wall 10 is a sound insulation material, and the sound insulation wall 10 plays a role in reducing ultrasonic working noise. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com