Test run system and method of low temperature air compressor

A low-temperature gas and compressor technology, which is applied in the field of low-temperature gas compressor commissioning, can solve the problems of difficulty in investment and land occupation, increase the number of equipment used and floor space, etc., and achieve stable and normal operation, reduce the amount of equipment, and reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

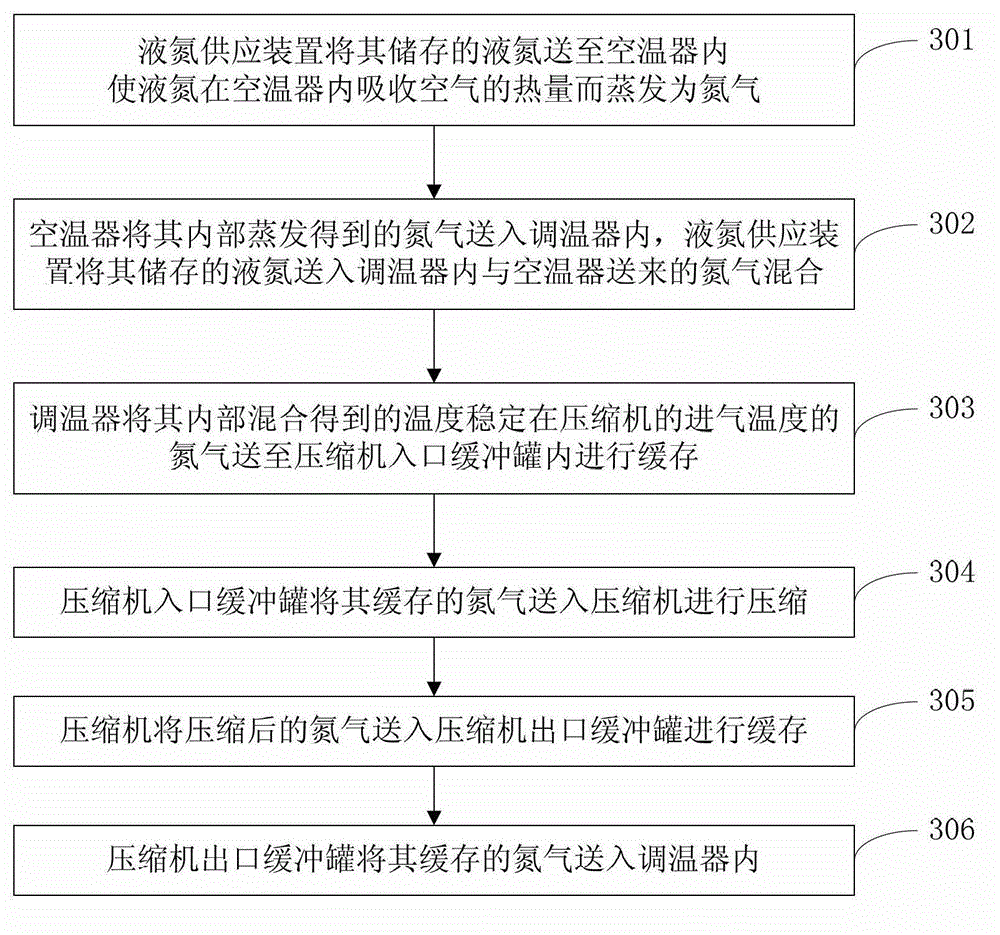

[0045]The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

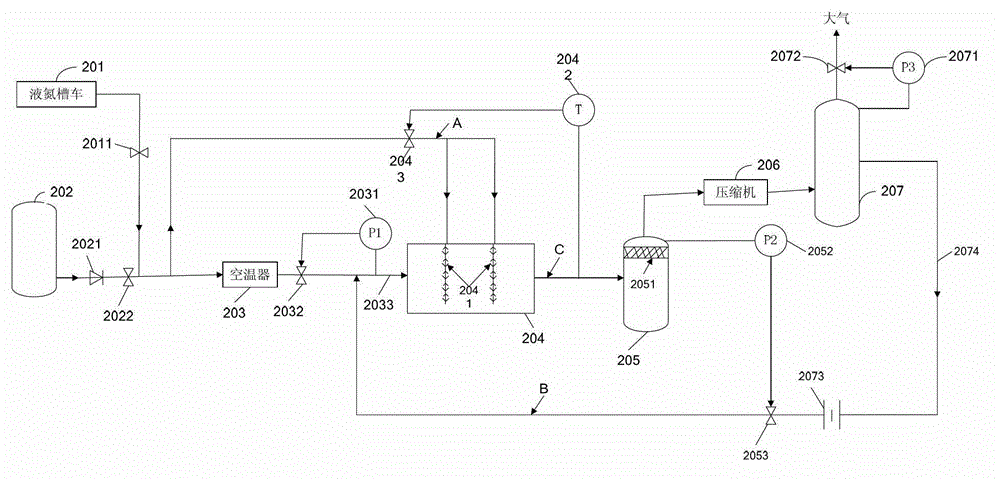

[0046] figure 2 It is a structural diagram of the test run system of the cryogenic gas compressor proposed by the present invention. Such as figure 2 As shown, the system includes: a liquid nitrogen supply device, an air cooler 203 , a thermostat 204 , a compressor inlet buffer tank 205 , a compressor 206 , and a compressor outlet buffer tank 207 . Wherein, the liquid nitrogen supply device can be realized by using the liquid nitrogen tank truck 201 , or by using the liquid nitrogen storage tank 202 , of course, it can also be realized by using the liquid nitrogen tank truck 201 and the liquid nitrogen storage tank 202 at the same time.

[0047] figure 2 Among them, the liquid nitrogen supply device is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com