A hydraulic control system and hydraulic test steel pipe machine oil-water balance system

A technology of hydraulic control system and water pressure test, which is applied to fluid pressure actuating system components, using stable tension/pressure to test the strength of materials, mechanical equipment, etc. Problems such as certainty and easy damage to the end face sealing ring, to achieve the effect of stable and reliable pressure following, suitable for popularization and use, and reliable and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

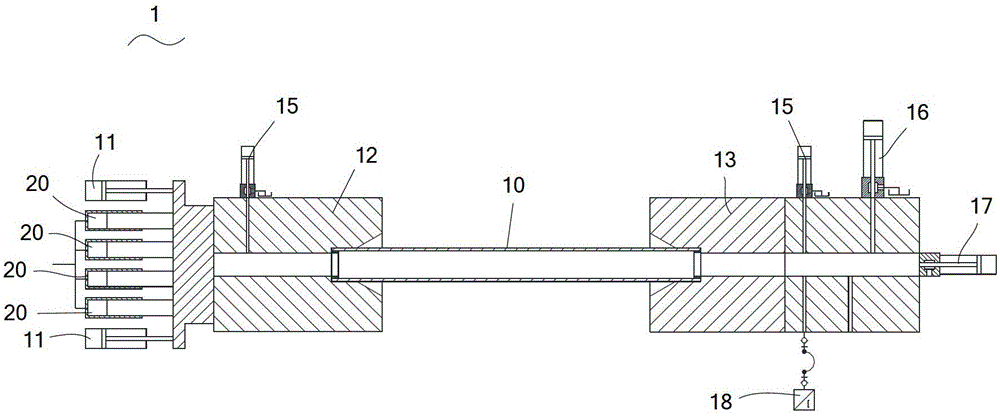

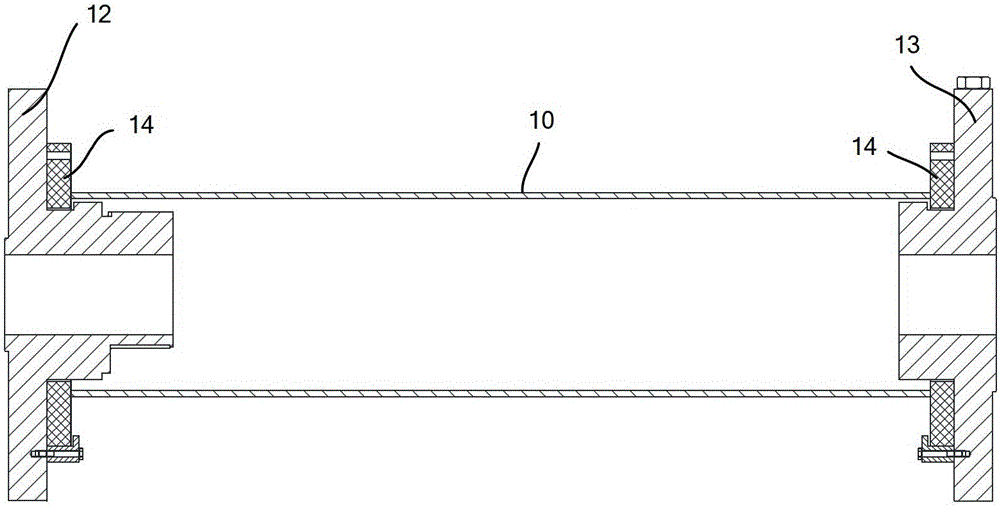

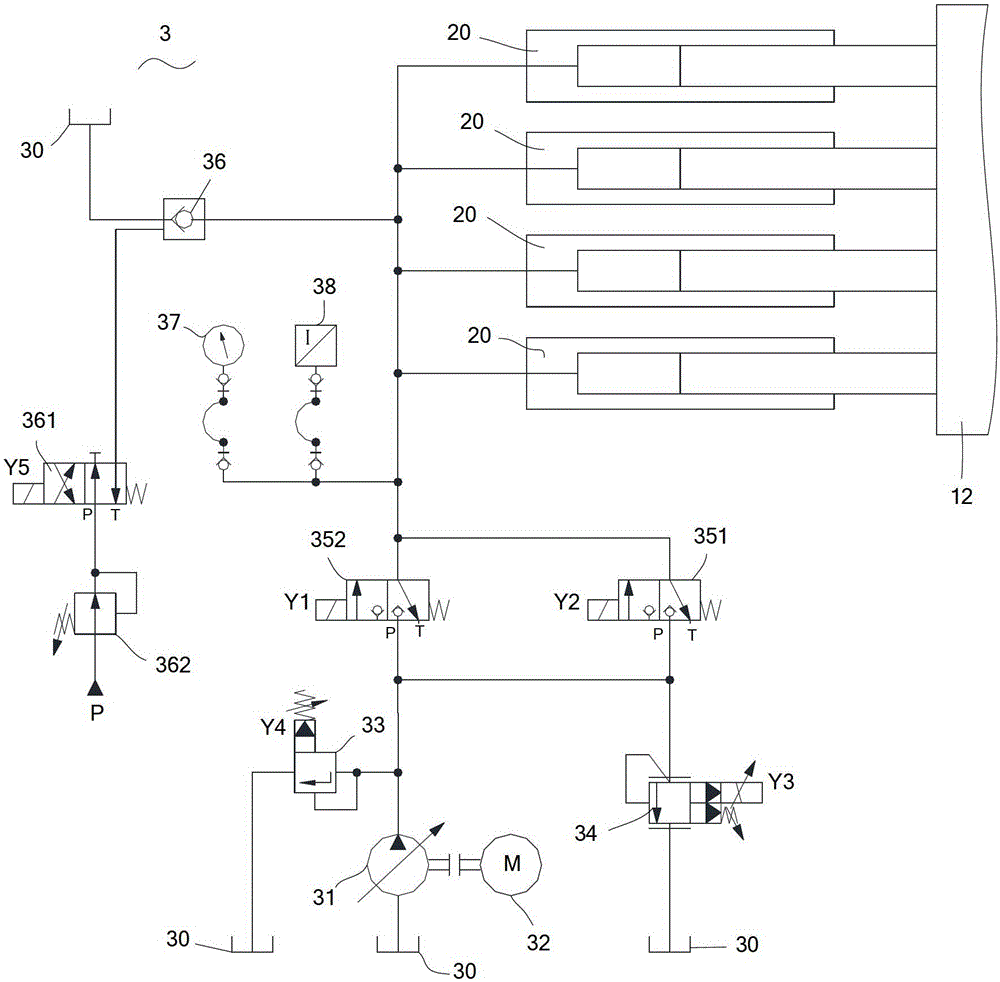

[0027] The principle of the hydraulic control system 4 for hydraulic test steel pipe machine oil-water balance of the present invention is as follows Figure 4 As shown, it includes 4 parallel main hydraulic cylinders 20, a high oil tank 40, a constant pressure variable pump 41, a motor 42, an electromagnetic overflow valve 43, a proportional overflow valve 44, a proportional pressure reducing valve 45, A filling valve 46 , a pressure gauge 47 and a pressure sensor 48 . The constant pressure variable pump 41 is driven by a motor 42 , the inlet of the constant pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com