Coiled plastic composite pipe reinforced with steel wire

A technology of reinforced plastics and composite pipes, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., to achieve the effect of convenient laying, small bending radius, hoop and axial strength and pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of a coilable steel wire reinforced plastic composite pipe provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

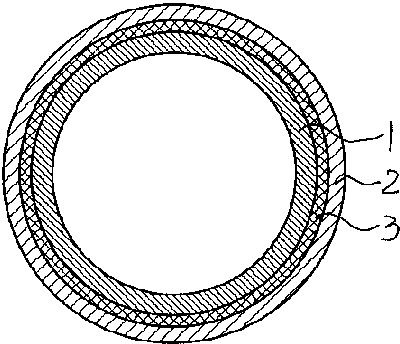

[0021] Such as figure 1 As shown, it is a radial cross-sectional structure diagram of a coilable steel wire reinforced plastic composite pipe provided by the present invention. The structure constituting the reinforced plastic composite pipe includes an inner pipe layer 1 and an outer pipe layer 2 made of high-molecular polymer materials. Between the outer wall of the inner pipe layer and the inner wall of the outer pipe layer, a layer with a tensile strength greater than 1700Mpa is wound or braided. 1. A steel wire reinforcement layer 3 with a diameter of 0.2-2.4mm. The above-mentioned inner tube layer 1, steel wire reinforcement layer 3 and outer tube layer 2 are combined into one structure.

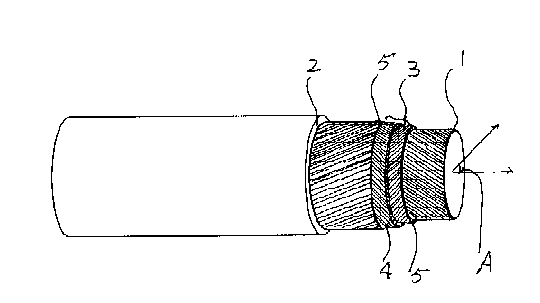

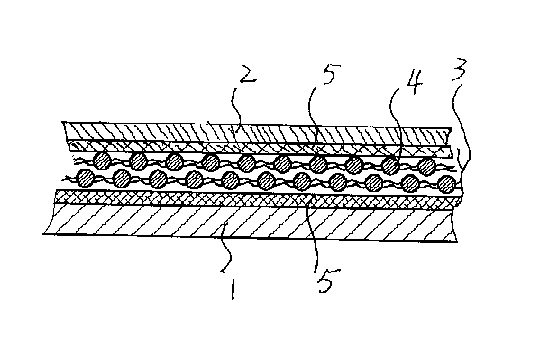

[0022] Such as figure 2 , 3 As shown, in the structure constituting the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com