Temperature control auxiliary water tank of solar water heating system

A technology of solar hot water and auxiliary water tanks, applied in the field of solar energy applications, can solve the problems of reducing the energy saving effect and economical efficiency of solar water heating systems, and achieve the effects of low cost, easy production, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

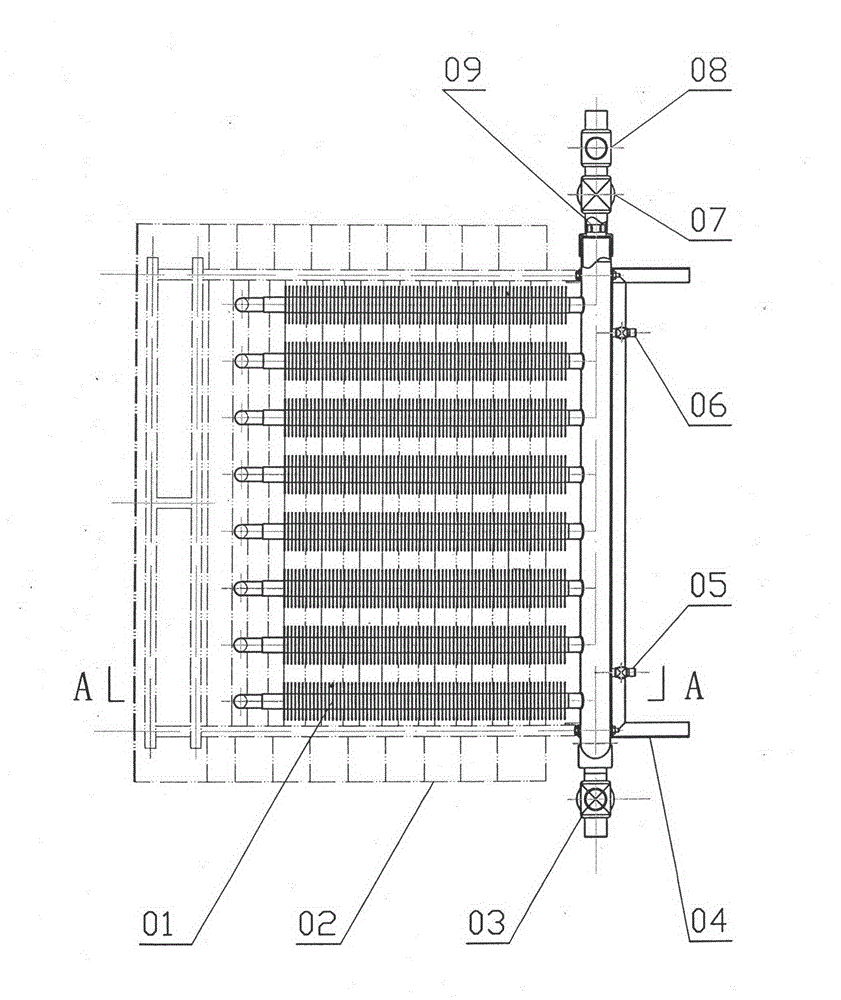

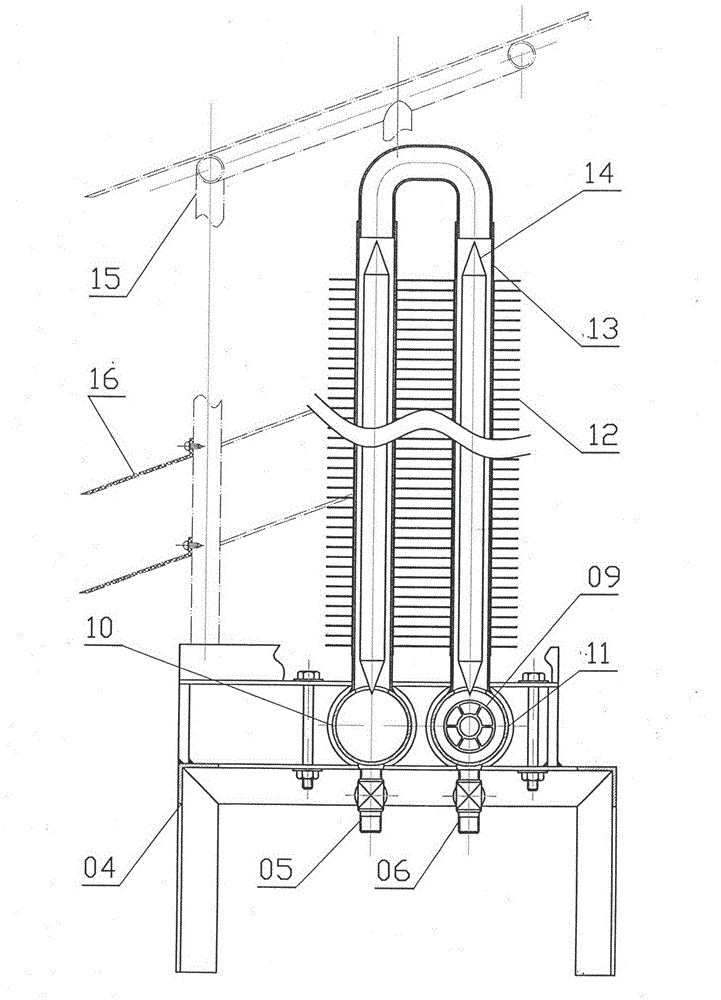

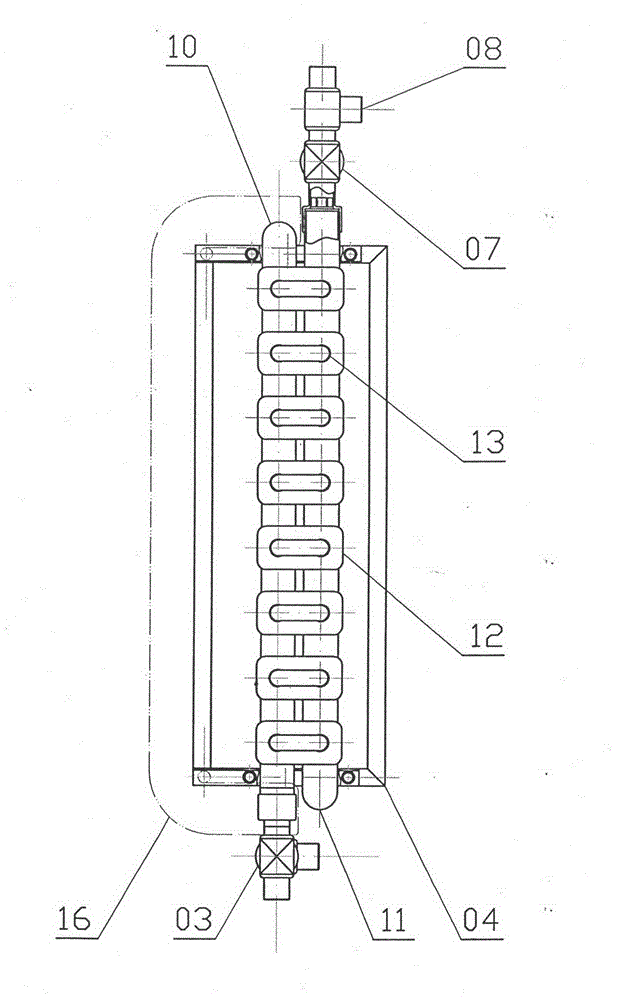

[0030] The accompanying drawings take the temperature-controlled auxiliary water tank of the solar water heating system as an example, and disclose specific embodiments of the present invention without limitation, and are also applicable to other types of solar water heating systems. The present invention is further described as follows in conjunction with the accompanying drawings.

[0031] See attached figure 1 , 2 And attached Figure 6 : the temperature control auxiliary water tank of the solar water heating system of the present invention, its structure mainly comprises awning 02, support 04, tee pipe joint 08, pipe structure radiator 01, overflow valve 09, drain valve 05 and 06, one-way Electromagnetic valve 07 and two-position three-way electromagnetic valve 03, one end interface of the one-way electromagnetic valve 07 is installed on the interface of the water outlet horizontal pipe 11 of the tube structure radiator 01, and the other end interface of the one-way elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com