Sensing optical fiber ring and all-fiber current transformer

A technology for sensing optical fiber rings and optical fiber rings, which is applied in the direction of polarized optical fibers, clad optical fibers, voltage/current isolation, etc., can solve the problems of affecting the measurement accuracy of current transformers, the indistinguishable output changes, and impracticality, so as to reduce the The effect of loss of optical signal in the optical path and degradation of optical polarization quality, improvement of integration degree, and elimination of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The all-fiber current transformer uses the Faraday effect of the sensing fiber to achieve measurement, that is, the magnetic field around the measured current wire causes two beams of circularly polarized light with different rotation directions in the sensing fiber to transmit at different speeds to generate a phase difference. After measuring the interference The amplitude of the signal can indirectly measure the magnitude of the current in the wire. When two beams of circularly polarized light with opposite rotations pass through the magneto-optical fiber, due to the Faraday effect, the propagation speed of the two beams of circularly polarized light changes, causing the phase difference between the two beams to change. By measuring the change of the interference light intensity between two coherent beams of light, the magnitude of the wire current can be indirectly measured.

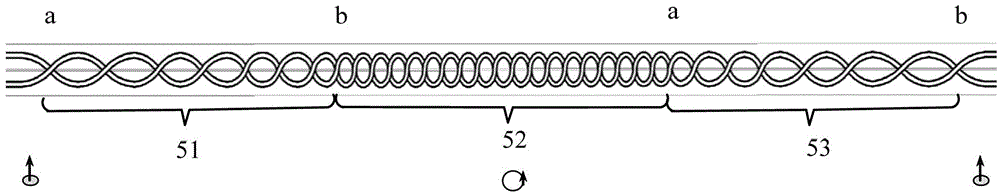

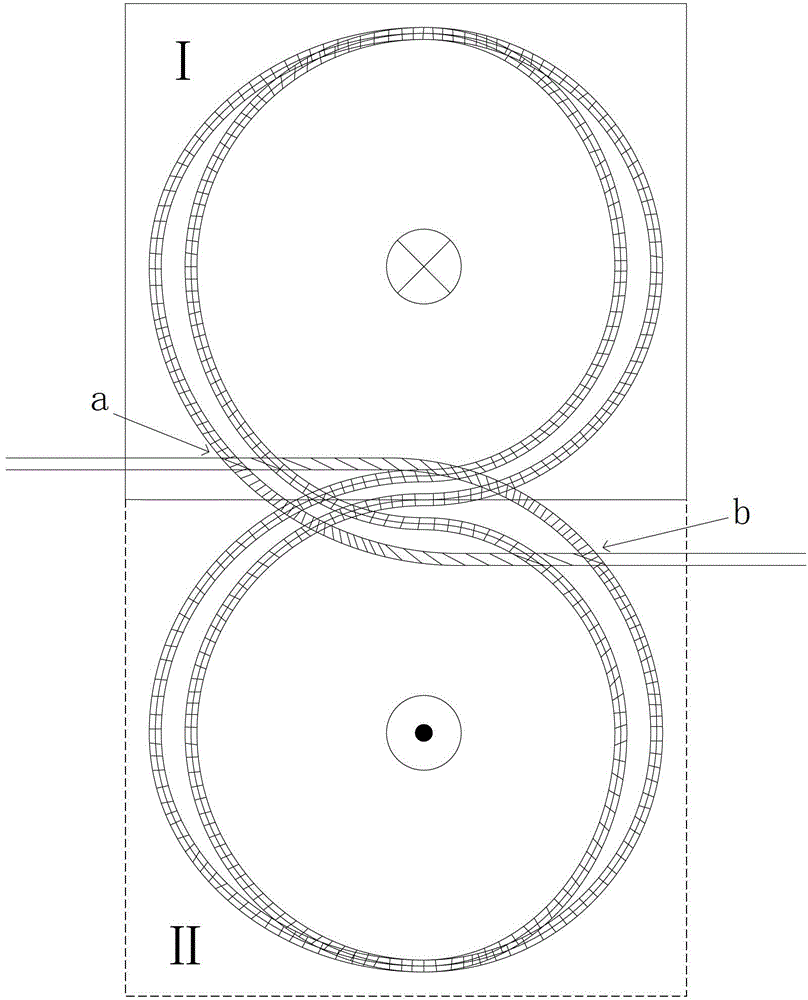

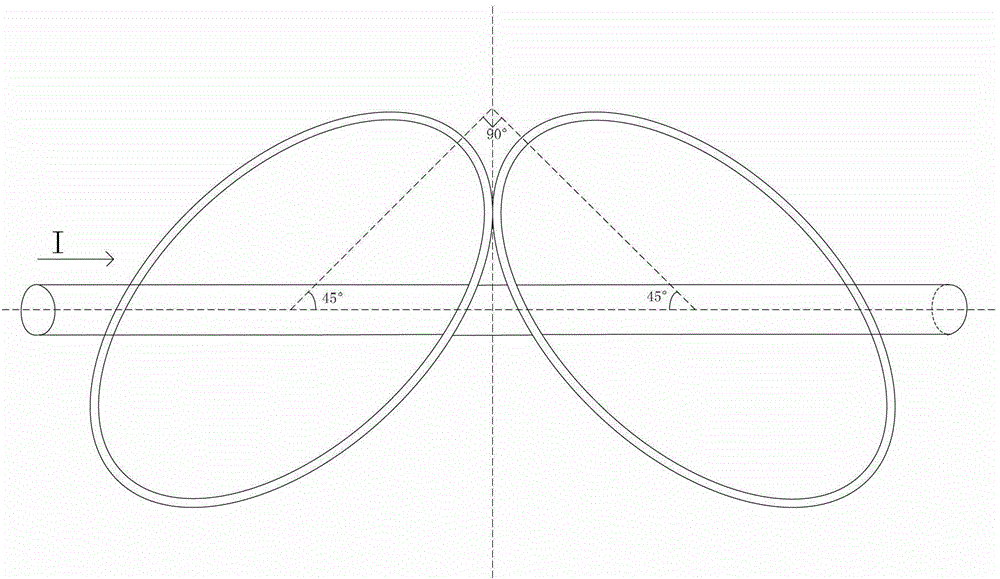

[0029] figure 1 It is a schematic diagram of the twisted optical fiber structure constitut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com