Method of manufacturing solid-state image pickup element, solid-state image pickup element, image pickup device, electronic apparatus, solid-state image pickup device, and method of manufacturing solid-state image pickup device

A technology of solid-state imaging elements and solid-state imaging devices, which is applied in the direction of electric solid-state devices, radiation control devices, electrical components, etc., can solve problems such as deterioration, sensitivity characteristics and shading characteristics, deviation color reproducibility and sensitivity characteristics, etc., to achieve reduction Loss, the effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 example

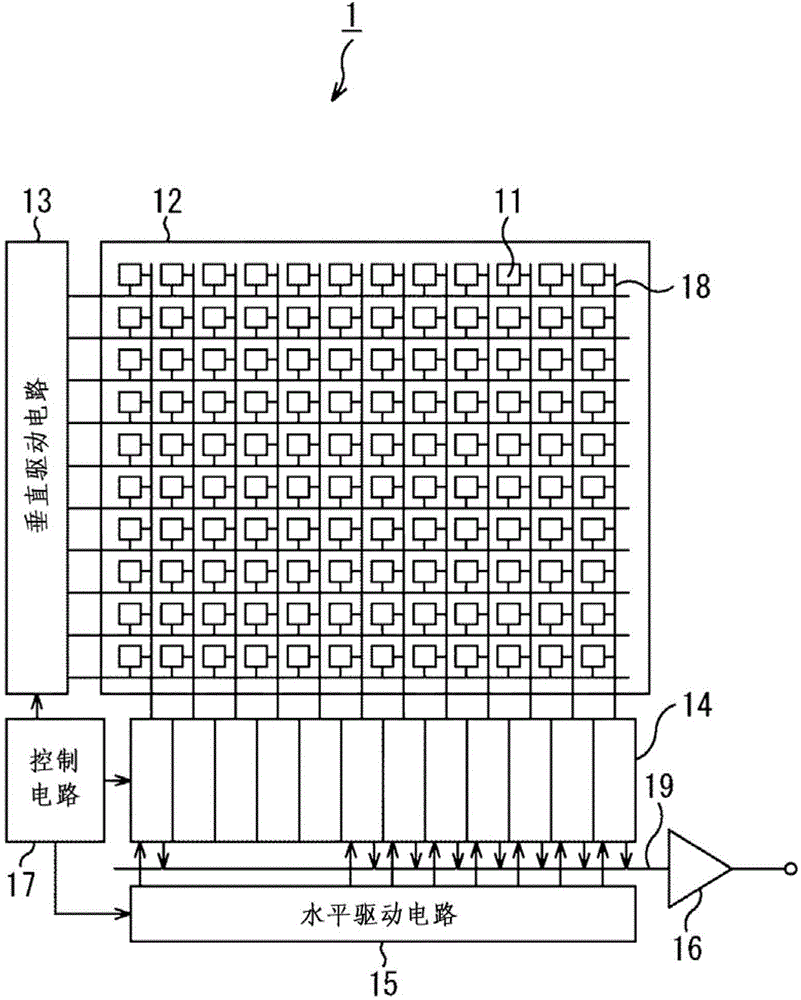

[0256] 6. Fourth Embodiment (Solid-State Imaging Device and Manufacturing Method Thereof)

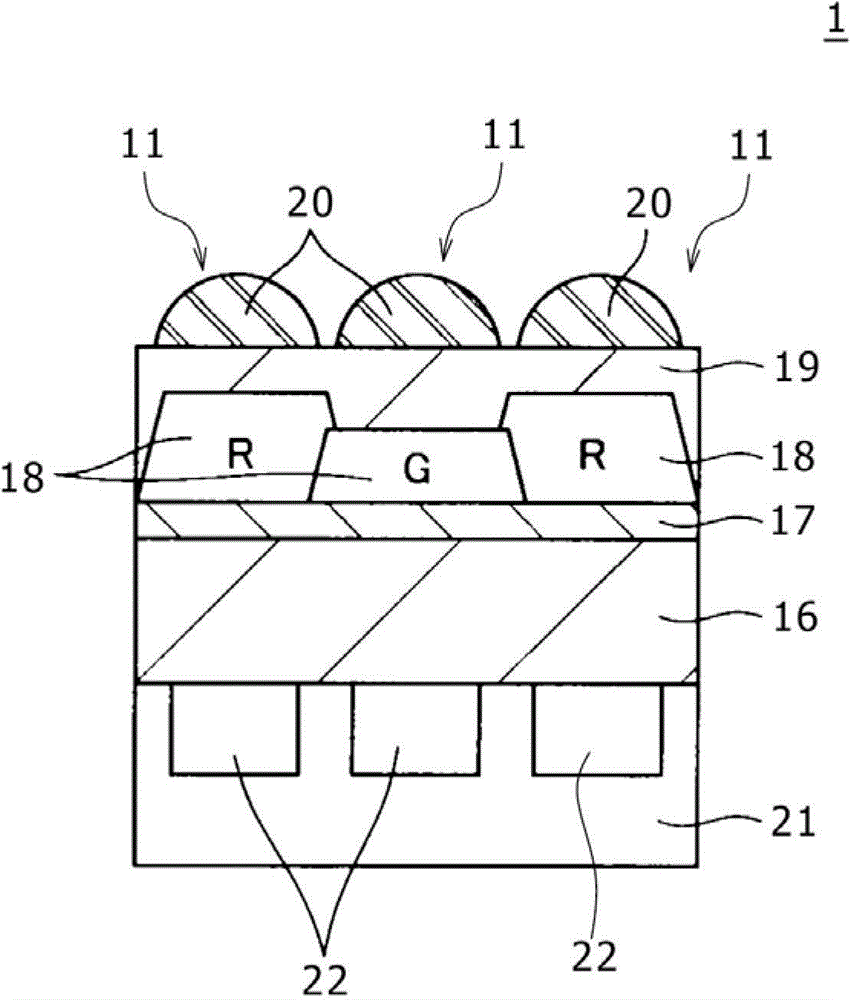

[0257] Figure 9 is a cross-sectional view showing the structure of the main part of the solid-state imaging element of the fourth embodiment of the present invention. Additionally, something like figure 2 The solid-state imaging element 1 of the first embodiment shown in and Figure 4 In the case of the solid-state imaging element 2 of the second embodiment shown in, Figure 9 A cross section of three pixels 11 of the solid-state imaging element 4 of the fourth embodiment is shown. Note that, in the solid-state imaging device 4 of the fourth embodiment, constituent elements corresponding to those in the solid-state imaging device 1 of the first embodiment are denoted by the same reference numerals or symbols, respectively, and are abbreviated here for simplification. Descriptions of them are appropriately omitted.

[0258] The solid-state imaging element 4 of the fourth embodimen...

no. 5 example

[0282] 7. Fifth Embodiment (Solid-State Imaging Device and Manufacturing Method Thereof)

[0283] Cross-sectional view of a pixel

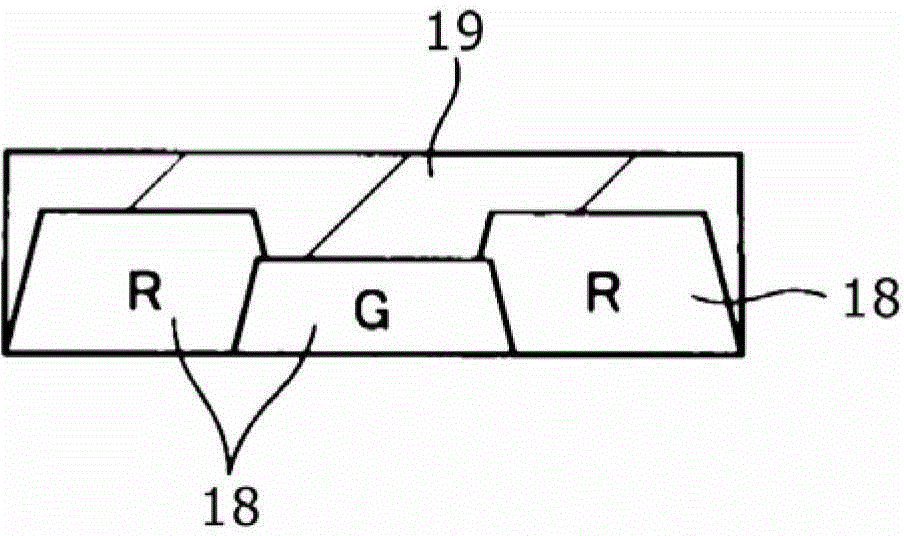

[0284] Figure 18 is a cross-sectional view showing a schematic structure of a pixel 211 within an effective pixel region 2121 of the solid-state imaging element 51 of the fifth embodiment of the present invention.

[0285] In pixel 211, as Figure 18 As shown in , a light receiving region 222 including a photodiode and the like is formed in a semiconductor substrate 221 such as a silicon substrate. A light shielding film 223 is formed in a boundary portion between respective adjacent pixels 211 on the semiconductor substrate 221 , and a planarizing film 224 is formed on the light shielding film 223 . In addition, a red (R), green (G) or blue (B) color filter 225 is formed on the planarization film 224 . As a material of the color filter 225 , a material obtained by adding an R, G, or B pigment as a dye to a photopolymerization negative photos...

no. 6 example

[0316] 8. Sixth Embodiment (Solid-state Imaging Device and Manufacturing Method Thereof)

[0317] Next, the pixel region 212 in the solid-state imaging element 61 of the sixth embodiment of the present invention will be described. It should be noted that, in the solid-state imaging device 61 of the sixth embodiment, constituent elements corresponding to those in the solid-state imaging device 51 of the fifth embodiment are denoted by the same reference numerals or symbols, respectively, and here for Descriptions of them are simplified and appropriately omitted.

[0318] The sixth embodiment is a solid-state imaging element 61 such as Figure 22An embodiment with a cavity structure is shown in . In this case, the effective pixel area 2121 is a concave central portion of the cavity structure, and the invalid pixel area 2122 is a peripheral portion formed slightly higher than the concave central portion. from Figure 22 In the first process shown in , it can be seen that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com