Novel motor controller heat dissipation system

A technology of motor controller and heat dissipation system, applied in cooling/ventilation/heating transformation, etc., can solve the problems of destroying the evaporation of thin liquid film layer, unable to apply heat dissipation, affecting heat dissipation efficiency, etc., to improve the heat dissipation limit, improve efficiency, and improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

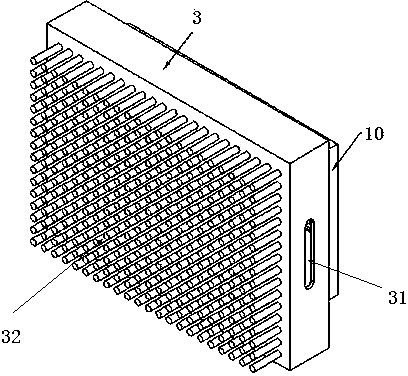

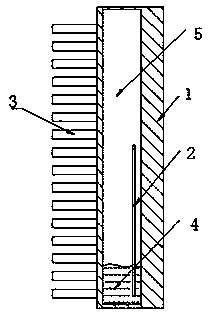

[0028] see figure 1 and image 3 , a novel motor controller heat dissipation system, comprising a sealed cavity 5, in which a liquid phase change medium 4 is arranged, and the phase change medium 4 is a new fluorocarbon compound, such as fluorocarbon nitrogen compound Fla or 3000, this type of compound has a suitable boiling point, does not corrode metals, and has high insulation, which improves the explosion-proof and corrosion resistance of the radiator, and greatly improves the reliability and safety. Compared with the traditional water-cooled radiator, the invention can prevent the motor controller from being affected by water leakage and dew condensation to damage the power components. The cavity wall has a micro-groove wall 1 and a heat dissipation wall 3, the outer surface of the micro-groove wall 1 is used to be close to the heating element 10, and the inner surface of the micro-groove wall 1 is provided with micro-channels 11. The heat dissipation wall 3 is provided...

Embodiment 2

[0032]On the basis of the above-described embodiment, the micro-channels 11 in this embodiment are arranged horizontally and vertically in a staggered manner, and the longitudinal micro-channels are arranged closely adjacent to each other, covering the entire micro-groove wall surface, and are used to seal the phase at the bottom of the sealed cavity 5. The variable medium is adsorbed by capillary action to form a thin liquid film on the microgroove wall; the horizontal microchannels 12 are arranged at intervals, mainly to make the adsorbed phase change medium more evenly distributed on the microgroove wall, so that Improve the evaporation efficiency of microgroove walls.

[0033] In this embodiment, the heat dissipation wall 3 can be positively arranged on the windward side of the electric vehicle. In order to make the cooling effect of the heat dissipation wall 3 better, the heat dissipation fins 32 provided on the outer surface of the heat dissipation wall 3 are removed, see...

Embodiment 3

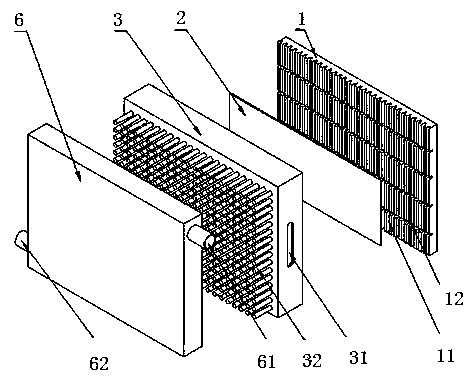

[0037] The cooling device positioned on the cooling wall 3 in the present invention can adopt the form of a cooling plate, as another embodiment of the present invention, in this embodiment as figure 2 As shown in , the cooling device is a water cooling device surrounded by a water-cooled plate cover 6 and a heat dissipation wall 3. The water-cooled plate cover 6 and the heat dissipation wall 3 form a cooling cavity, and the side of the water-cooled plate cover 6 is provided with a water inlet 61 and the water outlet 62, the cooling water enters the cooling cavity from the water inlet 61, and flows out from the water outlet 62 after exchanging heat with the cooling wall 3 and increasing the temperature. The water-cooled plate cover 6 in this embodiment can directly cool the heat dissipation wall 3 without the heat dissipation fins 32 , and this design is suitable for heat dissipation of a motor controller with a small power. The heat dissipation fins 32 can also be arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com