Method for processing bone graft material using teeth, and bone graft material processed thereby

A processing method and bone grafting technology, which is applied in the field of bone grafting materials, can solve the problems of low alveolar bone formation speed, limited amount of material, complicated treatment process, etc., and achieve good formation speed and the effect of solving immune problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Enamel powder

[0056] An example in which a crown of an extracted tooth is processed into powder will be described.

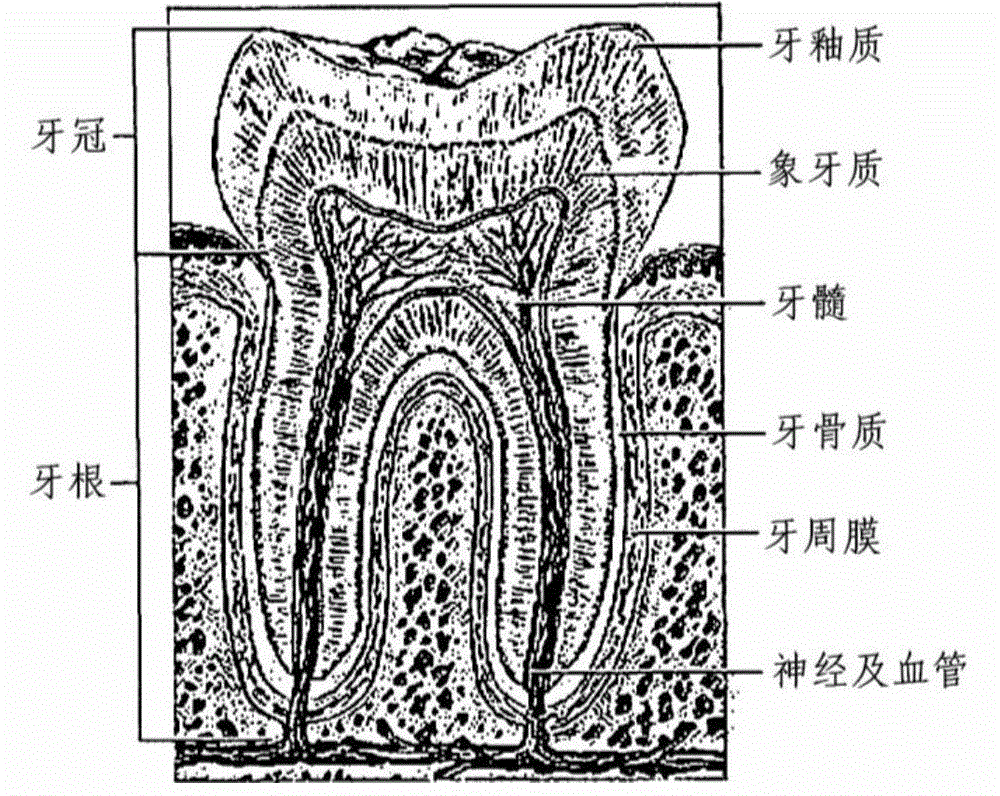

[0057] First, the image 3 The extracted tooth is shown in the Figure 4 and Figure 5 The interface between the crown and the root shown is truncated, and the extracted tooth is a pretreated tooth, and the above pretreatment is to remove the extracted caries or inflammation and other defective parts.

[0058] Such as Figure 6 As shown, after removing the soft tissue and pulp tissue in the crown, wash with distilled water for 30 minutes to 2 hours. Such as Figure 6 As shown, enamel and dentine remain in the crown after removal of soft tissue and pulp tissue.

[0059] Use liquid nitrogen from -160°C to -210°C, for example Figure 6 The dental crowns treated as shown were subjected to rapid freezing for 30 minutes to 2 hours, and then crushed with a pulverizer (Crushing), so that they were processed into such Figure 7 Powders with ...

Embodiment 2

[0068] Embodiment 2: dentin powder

[0069] An example in which a root of an extracted tooth is processed into a powder will be described.

[0070] First, the image 3 The extracted tooth is shown in the Figure 4 and Figure 5 The interface between the crown and the root shown is truncated, and the extracted tooth is a pretreated tooth, and the above pretreatment is to remove the extracted caries or inflammation and other defective parts.

[0071] Such as Figure 6 As shown, after removing the soft tissue and pulp tissue in the tooth root, wash with distilled water for 30 minutes to 2 hours. Such as Figure 6 As shown, dentin and cementum remain in the root after removal of soft tissue and pulp tissue.

[0072] With methods such as quick freezing of embodiment 1 and pulverizing dental crown, process such as Figure 6 The tooth roots shown were treated to make a powder with an average particle size of 200 to 1500 μm.

[0073] Using the same method as in Example 1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com