Method for manufacturing bionic flower made of compound fabric and capable of expanding under humidity control

A technology of composite fabrics and bionic flowers is applied in the field of textile imitation to achieve the effects of strong authenticity, suitable for viewing and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 A manufacturing method for absorbing water and automatically stretching leaves:

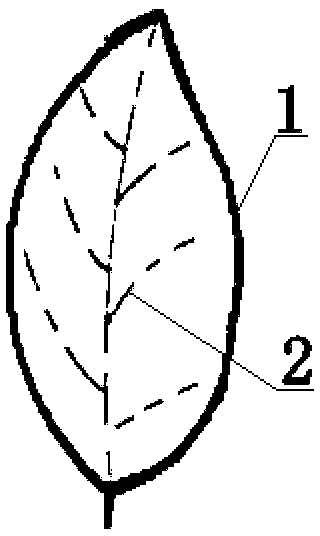

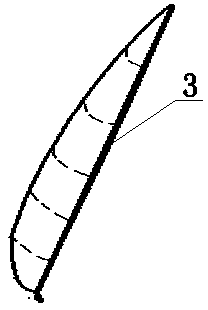

[0036] Such as Figure 1-2 As shown, the gram weight of cutting 2 pieces of elliptical plant leaf shape is 15g / m respectively 2 and 15g / m 2 The green polyester non-woven fabric 1 is completely spliced, and the layers are evenly filled with 10g / m 2 Weighted polylactic acid swelling fibers, after suturing around four weeks, press as figure 1 The pattern shown in step 1 is used to sew ribs, and branches 3 of other hard materials can be inserted or pasted in the middle of the interlayer. The branches 3 are generally made of plastic materials, and are made of figure 2 The leaf that absorbs water or absorbs moisture in the shown dry roll-up state can automatically expand, and the state after absorbing water and swelling is as follows: figure 1 shown.

[0037] In this embodiment, non-woven fabrics of the same grammage are used to replace the green polyester non-woven fabrics of th...

Embodiment 2

[0039] Example 2 A manufacturing method for absorbing water and automatically stretching leaves:

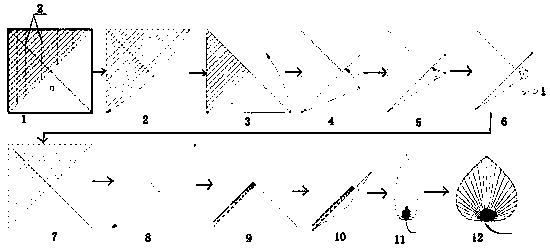

[0040] Such as image 3 As shown, take 2 pieces of 10×10cm and the weight is 15g / m 2 and 30g / m 2 green polypropylene non-woven fabric, press image 3 As shown in step 1, uniformly fill 30 g / m between the upper left half of the non-woven fabric 2 The weight of sodium polyacrylate resin particles, the blank part in the lower right corner is not filled with adsorption expansion material, and 7 ribs 2 are sewn at intervals of 1cm, 1cm, 2cm, 2cm, 2cm, 2cm and diagonally, and after sewing around, the Composite fabric of 10×10cm that can be automatically unfolded when it absorbs water (moisture absorption) when it is folded or rolled up;

[0041] Using the expandable composite fabric directly according to image 3 The method shown in steps 1 to 11 folds and makes a shape of a folded leaf (where the upper left corner folds the leaf surface in a Z shape, and the lower right corner...

Embodiment 3

[0042] Example 3 A kind of manufacture method of absorbing water and stretching red rose automatically:

[0043] Such as Figure 4 As shown, take several pieces of 10×10cm and their weights are 30g / m 2 and 50g / m 2 The red nylon non-woven fabric, according to Figure 4 After folding in steps 1 and 2, cut according to the pattern shown in step 3, unfold to form a petal shape as shown in step 4, and fill 40g / m evenly between the two laminated non-woven fabrics 2 The weight of expanded rubber granules, after sewing around the four sides, sew ribs 2 respectively as shown in step 4, in which the inner circle part is not filled with expanded rubber granules, that is, no filling material layer 4, and then gradually rolled up to form rosebuds, and the bottom is adhered On the branches 3 made of other hard materials, form the rose shape shown in step 5, and unfold after absorbing water, as shown in step 6 in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com