Tea tree oil antibacterial microcapsule and preparation method and application thereof

A technology of tea tree oil and microcapsules, which is applied in the direction of antibacterial drugs, pharmaceutical formulations, cosmetic preparations, etc., to achieve the effects of mild conditions, low equipment requirements, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

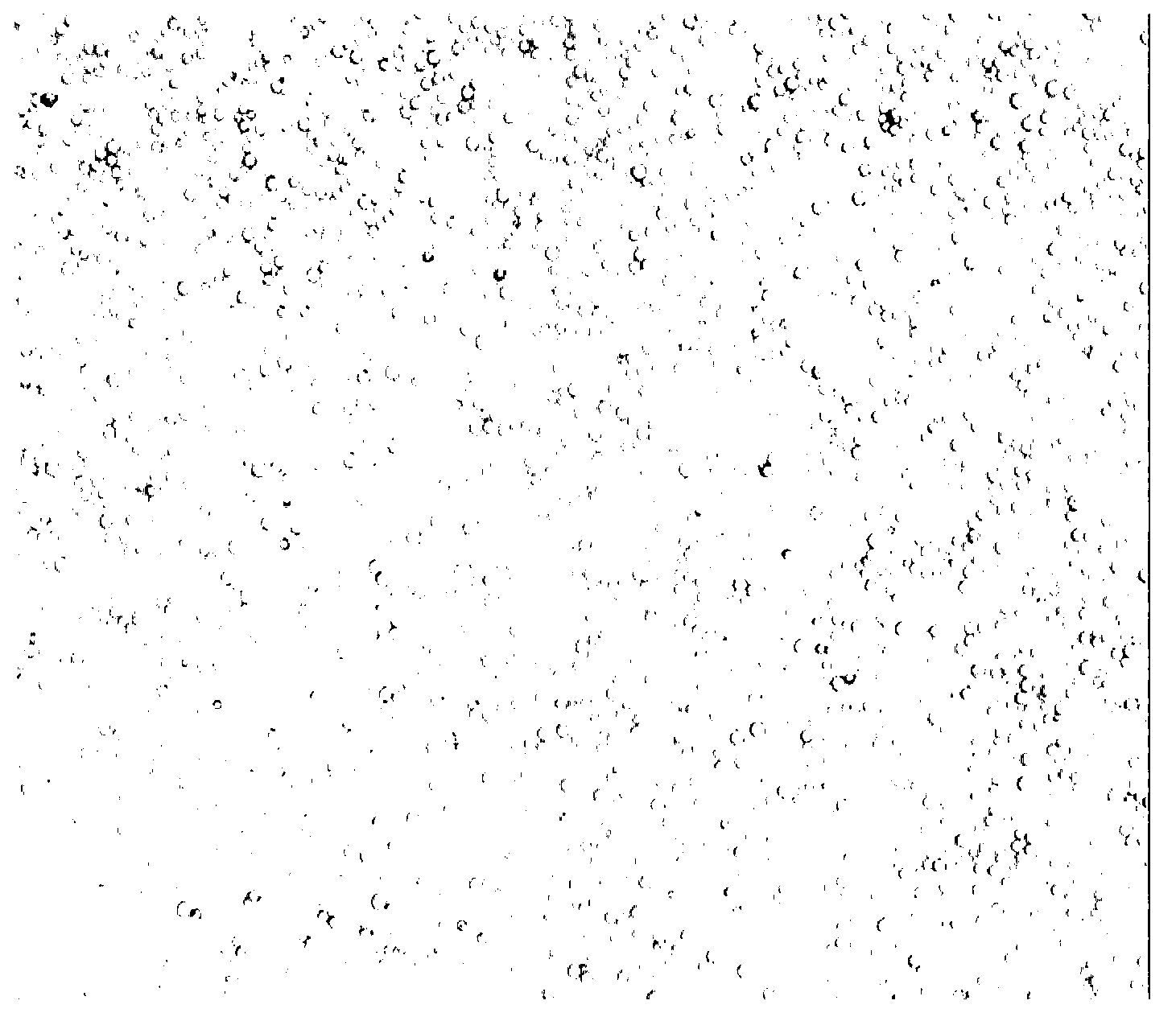

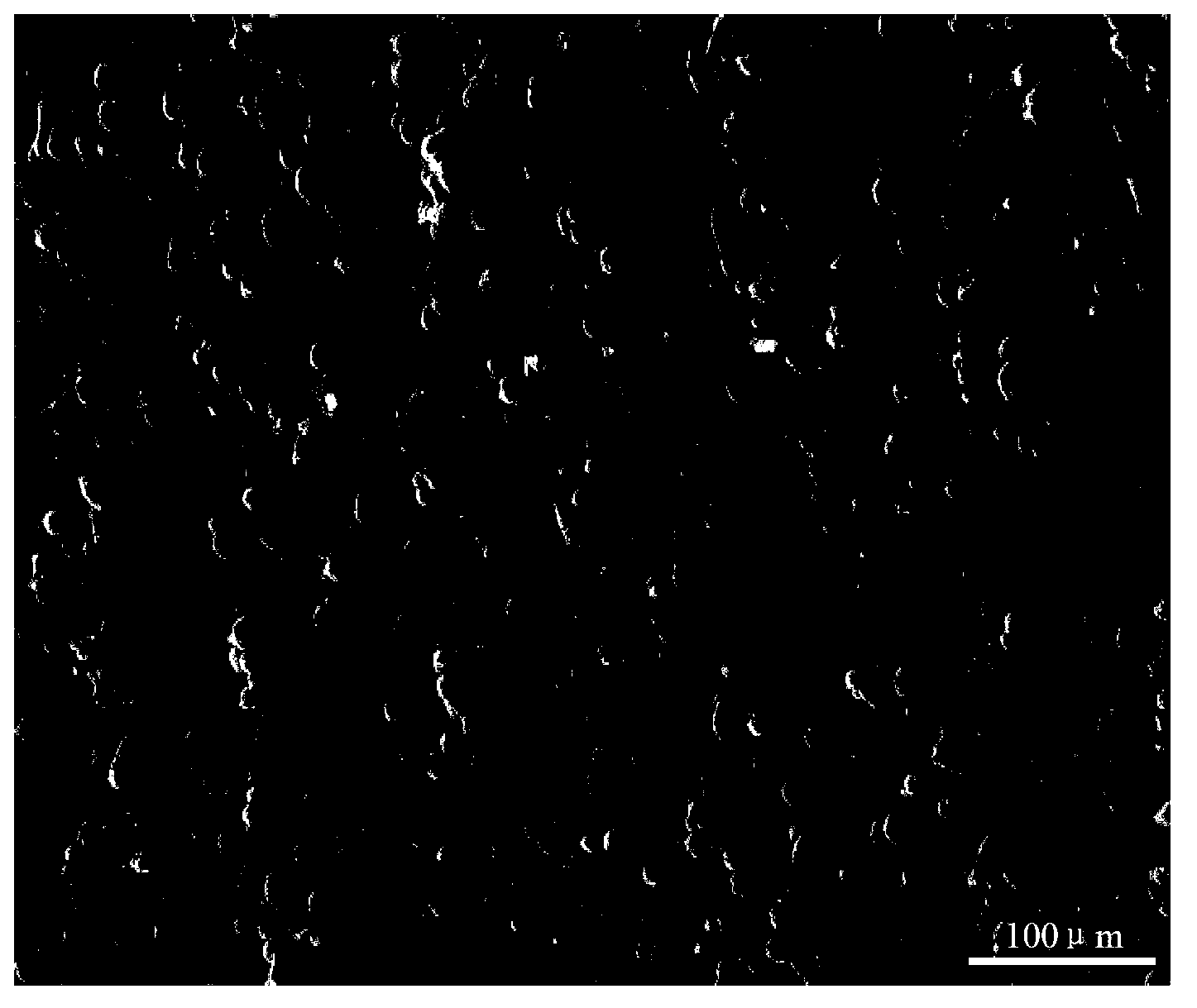

Image

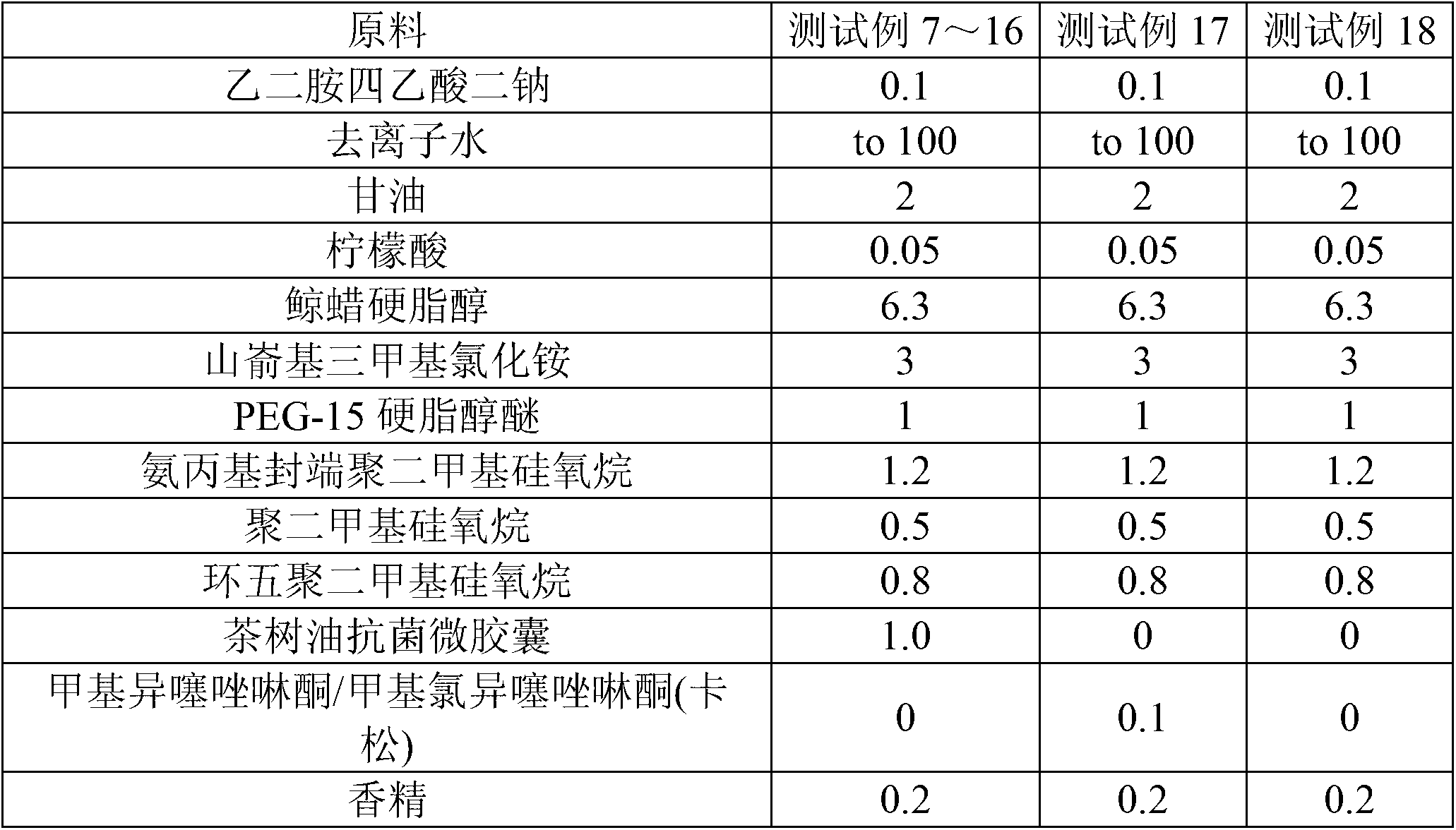

Examples

Embodiment 1

[0059] (1) Dissolve 2 mass parts carboxymethyl chitosan (CPCTS, molecular weight 50,000, carboxylation degree 70.0%, Zhejiang Jinke Biochemical Co., Ltd.) in 98 mass parts deionized water to prepare 2.0% mass fraction Carboxymethyl chitosan aqueous solution was added with 0.5 parts by mass of dimethyldiallylammonium chloride-acrylic acid copolymer (viscosity average molecular weight 4500, Guangzhou Chaohui Chemical Technology Co., Ltd.), stirred and dissolved to obtain solution I.

[0060] (2) Dissolve 3 parts by mass of chitosan (Chitosan, molecular weight 300,000, deacetylation degree 95.0%, Zhejiang Jinke Biochemical Co., Ltd.) in 97 parts by mass of deionized water, stir, and adjust the pH value to 3.0 with glacial acetic acid , chitosan is completely dissolved, and is prepared into a chitosan aqueous solution with a mass percentage of 3.0%; add 2 mass parts Tween-80 and 4 mass parts tea tree oil (cosmetic grade, Australia AusoilPTYLTD company), 4500r to the chitosan aqueou...

Embodiment 2

[0070] (1) 2 mass parts carboxymethyl chitosan (CPCTS, molecular weight 100,000, carboxylation degree 65.0%, Zhejiang Jinke Biochemical Co., Ltd.) was dissolved in 98 mass parts deionized water to prepare 2.0% mass fraction Add 0.2 parts by mass of polydimethyldiallylammonium chloride (viscosity average molecular weight: 3000, Guangzhou Chaohui Chemical Technology Co., Ltd.) to an aqueous solution of carboxymethyl chitosan, stir and dissolve to obtain solution I.

[0071] (2) Dissolve 3 parts by mass of chitosan (Chitosan, molecular weight 500,000, degree of deacetylation 95.0%, Zhejiang Jinke Biochemical Co., Ltd.) in 97 parts by mass of deionized water, stir, and adjust the pH value to 3.0 with glacial acetic acid , make chitosan dissolve completely, be mixed with the chitosan aqueous solution of mass percent 3.0%; Add 0.5 mass part Tween-20, 0.5 mass part Span-80 and 2 mass parts tea tree oil (cosmetics) in chitosan aqueous solution Grade, Australia Ausoil PTY LTD company),...

Embodiment 3

[0075] (1) Dissolve 2 mass parts carboxymethyl chitosan (CPCTS, molecular weight 80,000, carboxylation degree 67.85%, Zhejiang Jinke Biochemical Co., Ltd.) in 98 mass parts deionized water to prepare 2.0% mass fraction Carboxymethyl chitosan aqueous solution was added with 0.4 parts by mass of dimethyldiallylammonium chloride-acrylamide copolymer (viscosity average molecular weight: 5000, Guangzhou Chaohui Chemical Technology Co., Ltd.), stirred and dissolved to obtain solution I.

[0076] (2) Dissolve 3 parts by mass of chitosan (Chitosan, molecular weight 450,000, degree of deacetylation 95.0%, Zhejiang Jinke Biochemical Co., Ltd.) in 97 parts by mass of deionized water, stir, and adjust the pH value to 3.0 with glacial acetic acid , chitosan is completely dissolved, and is prepared into an aqueous chitosan solution with a mass percentage of 3.0%; 2 mass parts Tween-80 and 3 mass parts tea tree oil (cosmetic grade, Australia Ausoil PTY LTD company) are added to the chitosan a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com