Method for cooling condensed fire extinguishing aerosol by using water or water solution

An aqueous solution and fire-extinguishing gas technology, applied in fire rescue and other directions, can solve the problems of increasing the manufacturing cost and use cost of aerosol fire-extinguishing devices, reducing the efficiency of aerosol fire-extinguishing, a large number of chemical cooling substances, etc. The effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

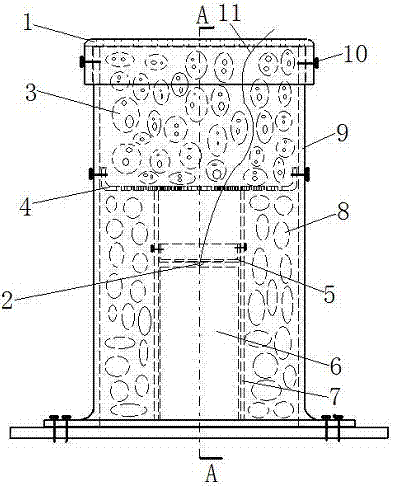

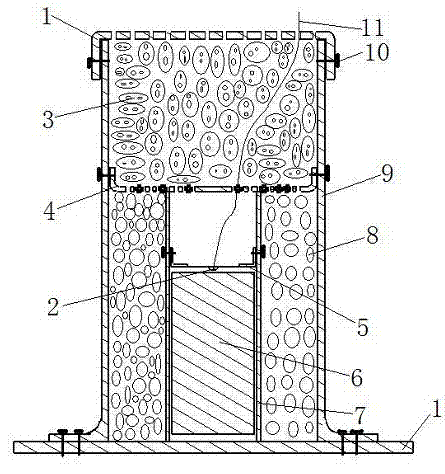

[0013] Embodiment one, as figure 1 , figure 2 Shown is a fire extinguishing hot aerosol generating device cooled by aqueous solution, wherein the aqueous solution ball 8 is a fire extinguishing aerosol cooling agent, which is made of an aqueous solution made of sodium bicarbonate dissolved in water, and then wrapped by a plastic film. structure. The outer orifice plate 1 is connected to the upper end of the casing 9 through the riveting parts 10, and the lower end of the casing 9 is connected to the bottom plate 12 of the cartridge 7 through the riveting parts 10, and the inner orifice plate 4 is arranged in the casing 9 and connected with the riveting parts 10 . The ventilation space between the inner orifice plate 4, the outer orifice plate 1 and the housing 9 is provided with microporous lightweight ceramsite 3 to form a mixing and filtering area of the aerosol generating device. The upper end of the cartridge 7 is loosely connected with the inner hole plate 4, the ca...

Embodiment 2

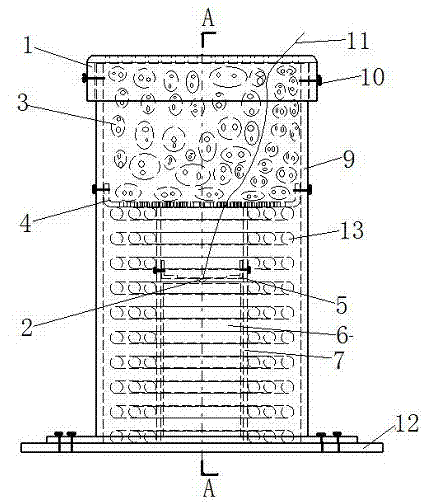

[0014] Embodiment 2, as image 3 and Figure 4 , the water-based fire extinguishing agent ring 13 is a fire-extinguishing hot aerosol cooling agent, which is a ring structure formed by the water-based fire extinguishing agent wrapped by a rubber film; the water-based fire extinguishing agent ring 13 surrounds the periphery of the cartridge 7 of the aerosol generating device, and other structures are implemented with the same structure Embodiment 1, when the aerosol generating agent 6 in the cartridge 7 of the aerosol generating device reacts, a large amount of heat will be generated, and the water system fire extinguishing agent ring 13 will gradually rupture, and the water system fire extinguishing agent therein absorbs heat and evaporates, and combines with the gas The sol is mixed and released at the microporous lightweight ceramsite 3 to implement the purpose of fire extinguishing.

[0015] Through actual testing, when the aerosol generating agent 6 in the cartridge 7 of ...

Embodiment 3

[0016] Example 3, such as Figure 5 , the cooling liquid 14 is water or an aqueous solution, and the structure of the device is similar to that of Embodiment 1, only the lower surface of the inner hole plate 4 is coated with a sealing film 15, and the riveting part 10 between the upper cartridge sealing cover 5 and the cartridge 7 is cancelled. In this way, the heat generated when the aerosol generating agent 6 reacts will cause the sealing film 15 to rupture, and the cooling solution will vaporize and absorb heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com