Method and device for controlling welding process based on stability of perforated molten bath

A technology of welding process and control method, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problem of welding arc deviating from the welding seam, etc., and achieve the effect of high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

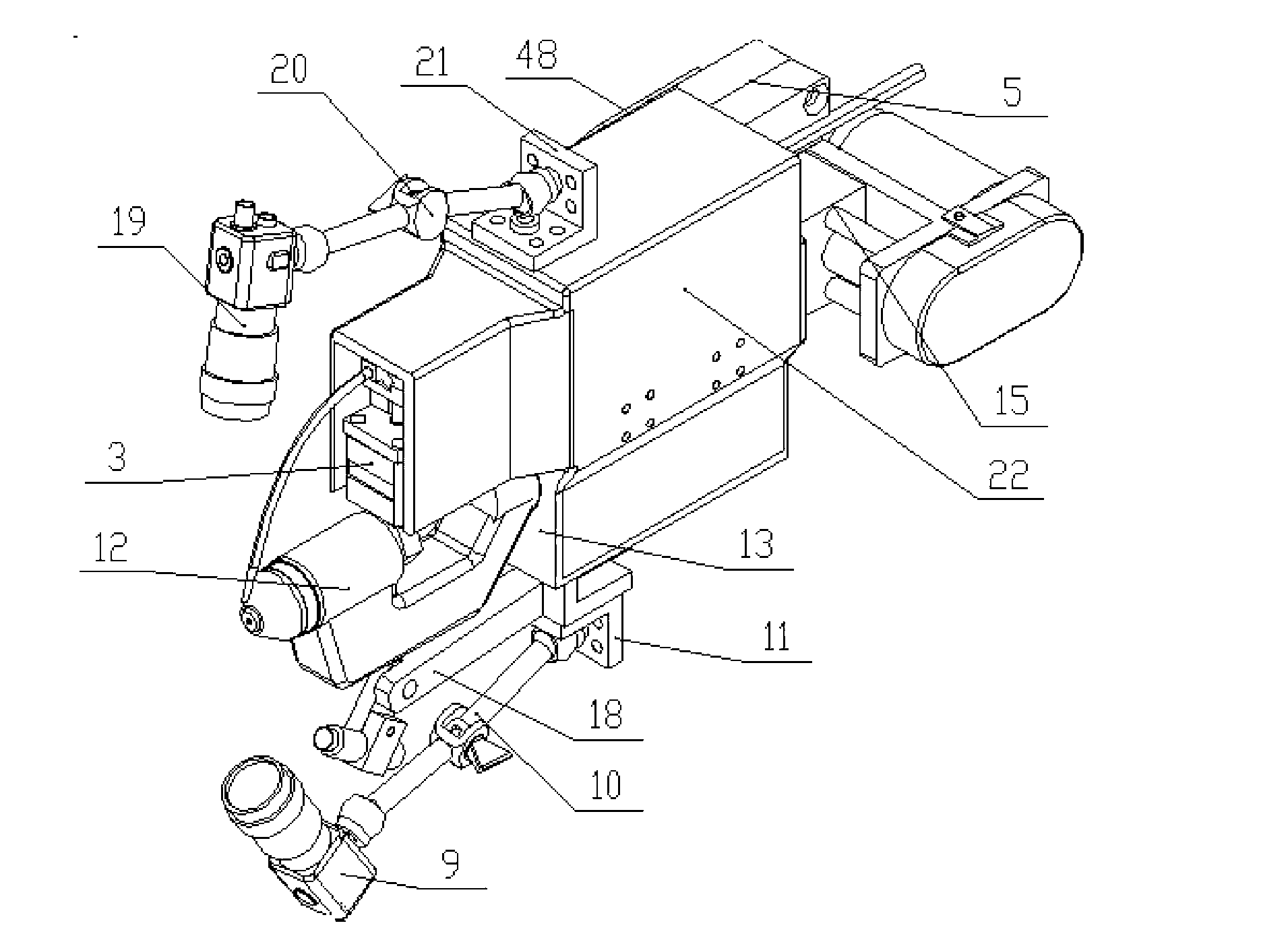

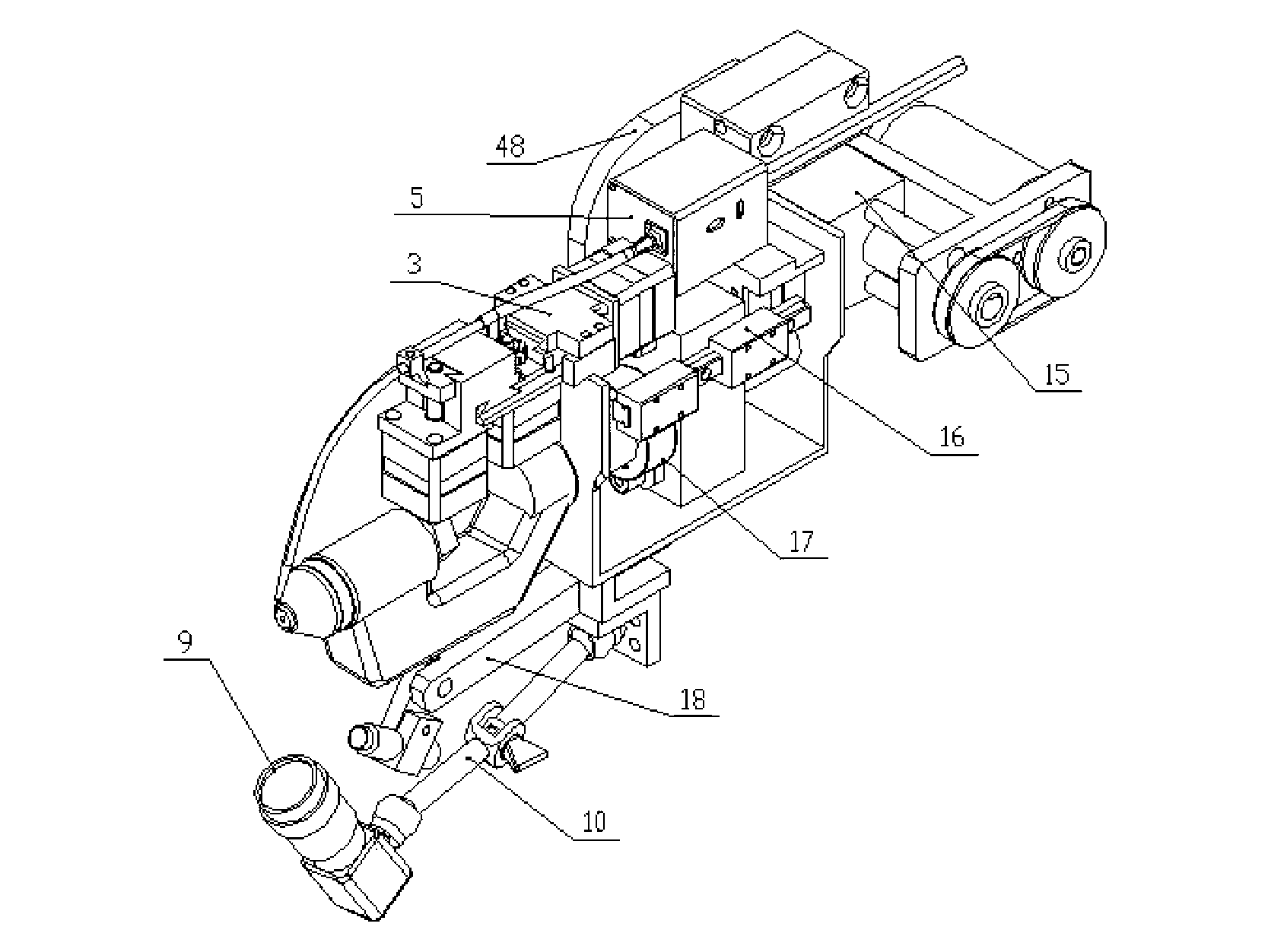

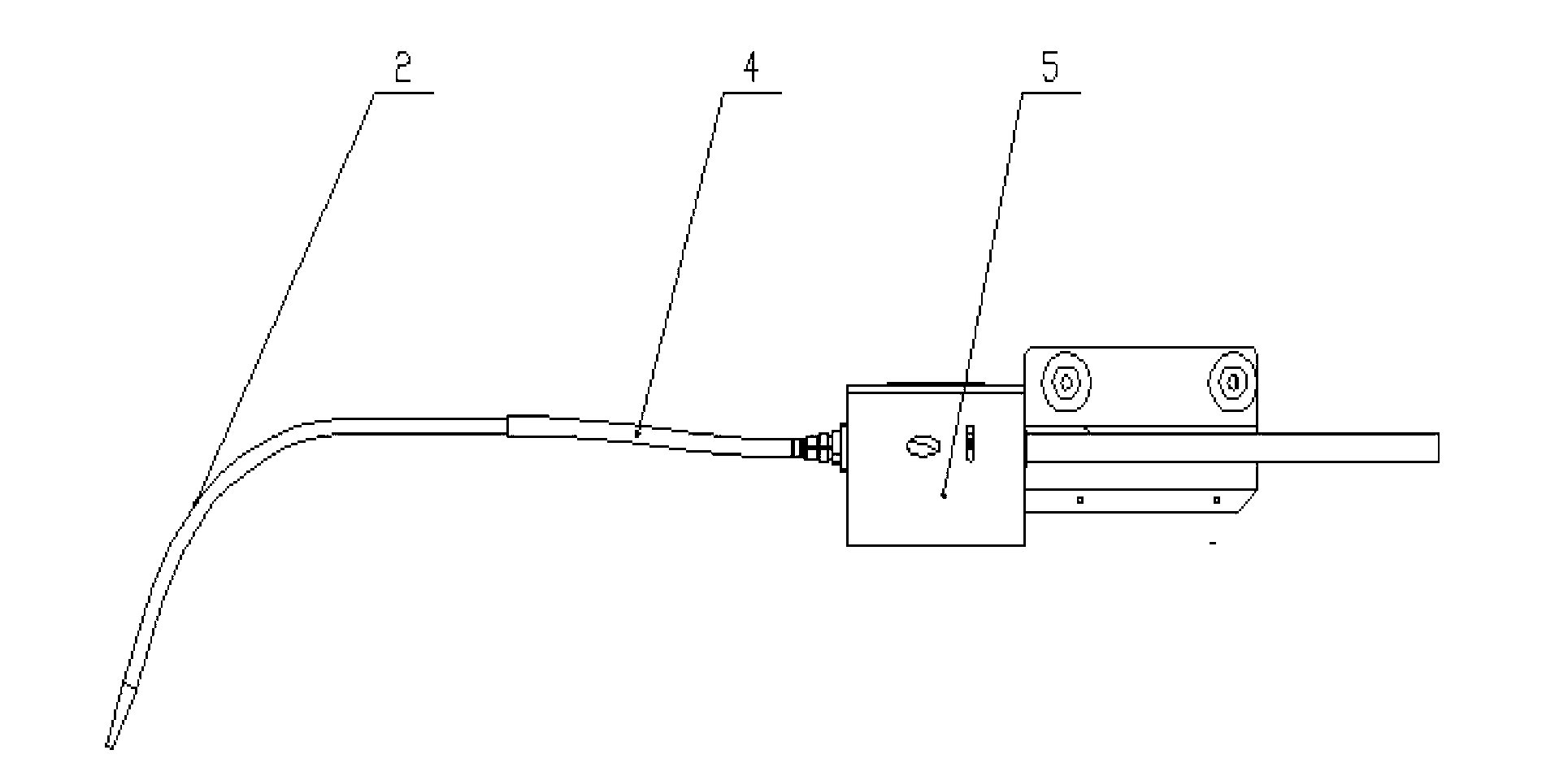

[0036] The structure of the present invention is as figure 1 , figure 2 As shown, the special head for plasma welding includes three-dimensional guide wire adjustment mechanism 3, wire feed regulator 5, plasma welding torch 1, welding torch circumferential adjustment mechanism 17, welding torch axial adjustment mechanism 16, lateral movement adjustment device 15, and arc video monitoring Camera device Ⅰ19, arc video surveillance camera device Ⅱ9, flexible adjustment bracket Ⅰ20, flexible adjustment bracket Ⅱ10, guide wire nozzle 2, guide wire hose 4, L-shaped connecting plate Ⅰ21, L-shaped connecting plate Ⅱ11 and frame Ⅰ22, frame Ⅱ13. The plasma welding torch 1 and the welding torch circumferential rotation adjustment mechanism 17 are installed on the welding torch axial adjustment mechanism 16. The welding torch axial adjustment mechanism 16 passes through the linear guide Ⅰ 6, the linear guide Ⅱ 26 and the slider Ⅰ, Ⅱ, Ⅲ, Ⅳ 7, 8, 12, 14 is installed on frame Ⅰ, frame Ⅰ 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com