Vertical friction stud welding method

A friction stud welding and stud technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult to break the oxide film on the surface of aluminum materials, deteriorate the joint strength, and easily produce hard and brittle problems, and achieve Simple and feasible equipment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

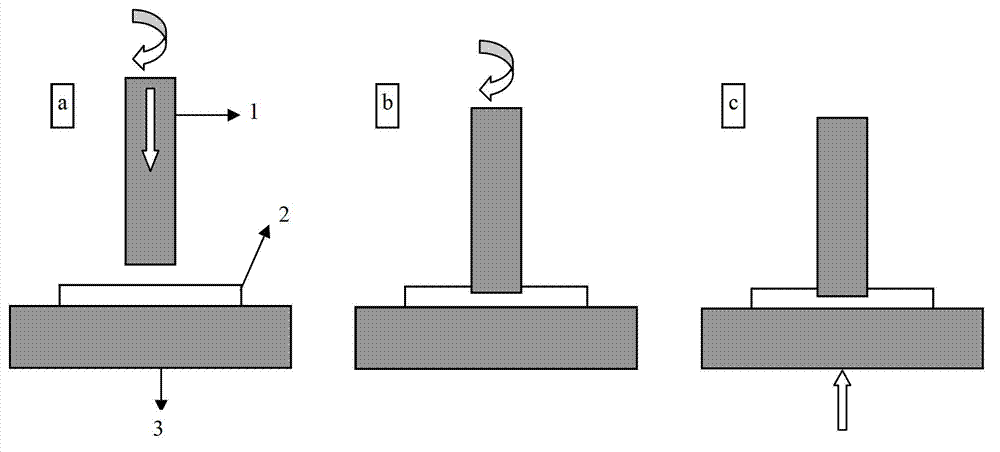

[0041] In order to solve the welding of dissimilar metal friction stud welding, if the friction stir spot welding process of aluminum plate / steel stud is used for friction stud welding of dissimilar metals, the tools used for friction stir spot welding are replaced by steel studs for stud welding, and When canceling the stud extraction process, two major problems arise:

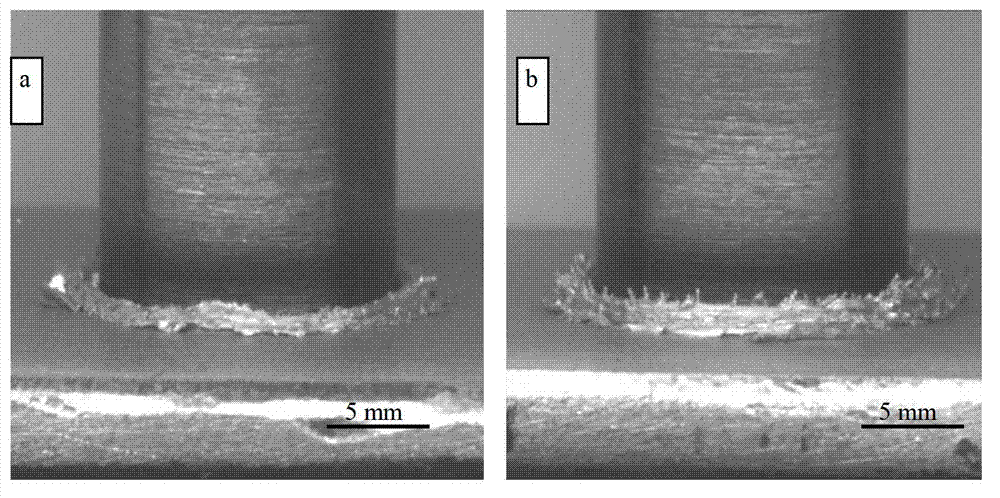

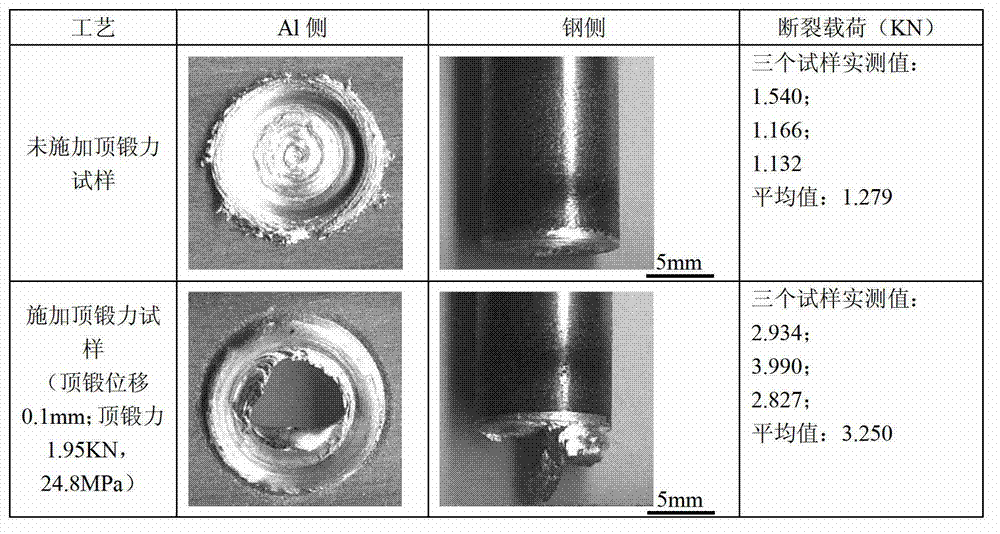

[0042] One is that although the aluminum plate can be firmly adhered to the end of the steel stud, cracks appear in the base metal of the aluminum plate (with the continuous welding of the interface, the real instantaneous friction interface gradually transfers from the original interface to the weak base material with lower strength , the torsion cracks of the secondary friction surface appeared in the weak base metal), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com